High temperature lead-free glaze health cup and its production technique

A health care cup and lead-free glaze technology, applied in drinking utensils and other directions, can solve the problems of reducing infrared emissivity, destroying the performance of far-infrared ceramic materials, and not being perfect, and achieving the effect of good functional effect, beautiful appearance and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

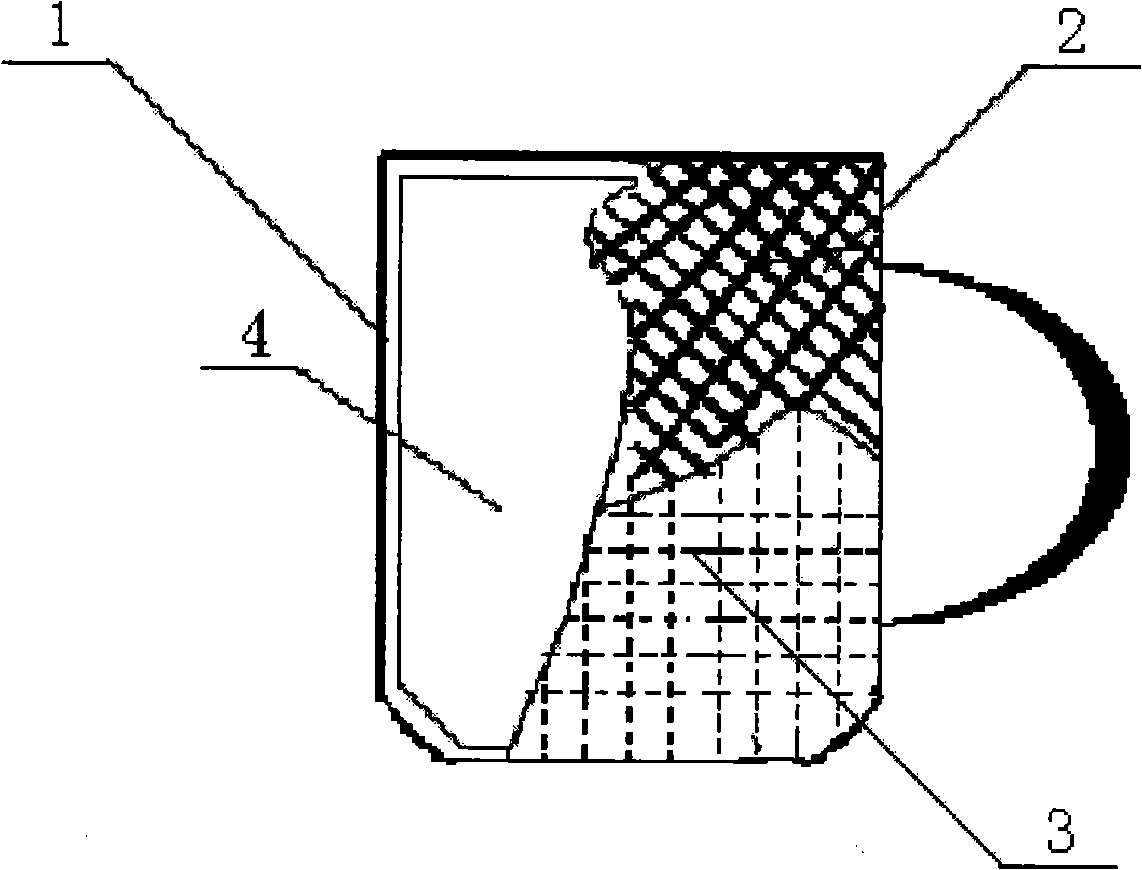

[0024] A high-temperature lead-free glaze health care cup as shown in the accompanying drawing, the main body is a cup body 1, which is characterized in that: the cup body 1 is a ceramic body, and a layer of high-temperature far-infrared lead-free glaze is fired on the inner wall of the ceramic body The material layer 2 is fired with a layer of glass glaze layer 3 on the high-temperature far-infrared lead-free glaze material layer 2 .

[0025] A pattern layer 4 is baked on the outer surface of the cup body 1 .

[0026] The high-temperature far-infrared lead-free glaze is sprayed on the inner wall of the cup body by spraying, dried and then put into a high-temperature furnace for firing.

[0027] A manufacturing process of a high-temperature lead-free glaze health care cup. The far-infrared material is sprayed on the inner wall of the ceramic cup through the inner coating method, and it is firmly integrated with the ceramic body after firing. To solve this problem, a A high-te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com