Production method of foldable filter element with high filtration flux

A kind of technology of folding filter element and manufacturing method, applied in the direction of gravity filter, etc., can solve the problems of reducing the service life of the filter element, reducing the recovery rate of the filter membrane flux, decreasing the filtration flux, etc., so as to avoid dead angles and increase the effective filter area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to further describe the technical solution of the present invention, the following will be described in detail in conjunction with the accompanying drawings and embodiments of the specification.

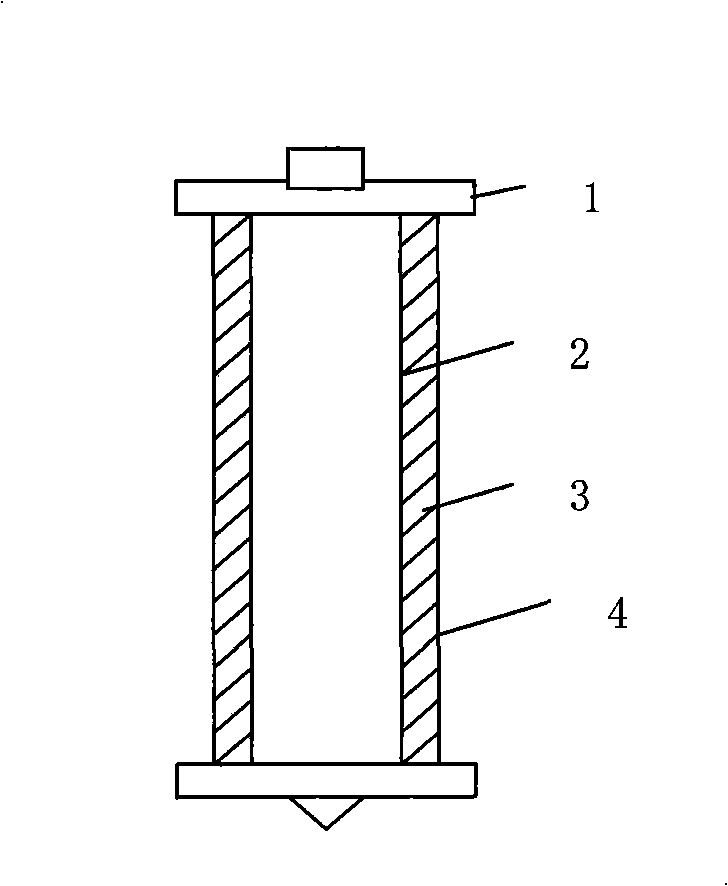

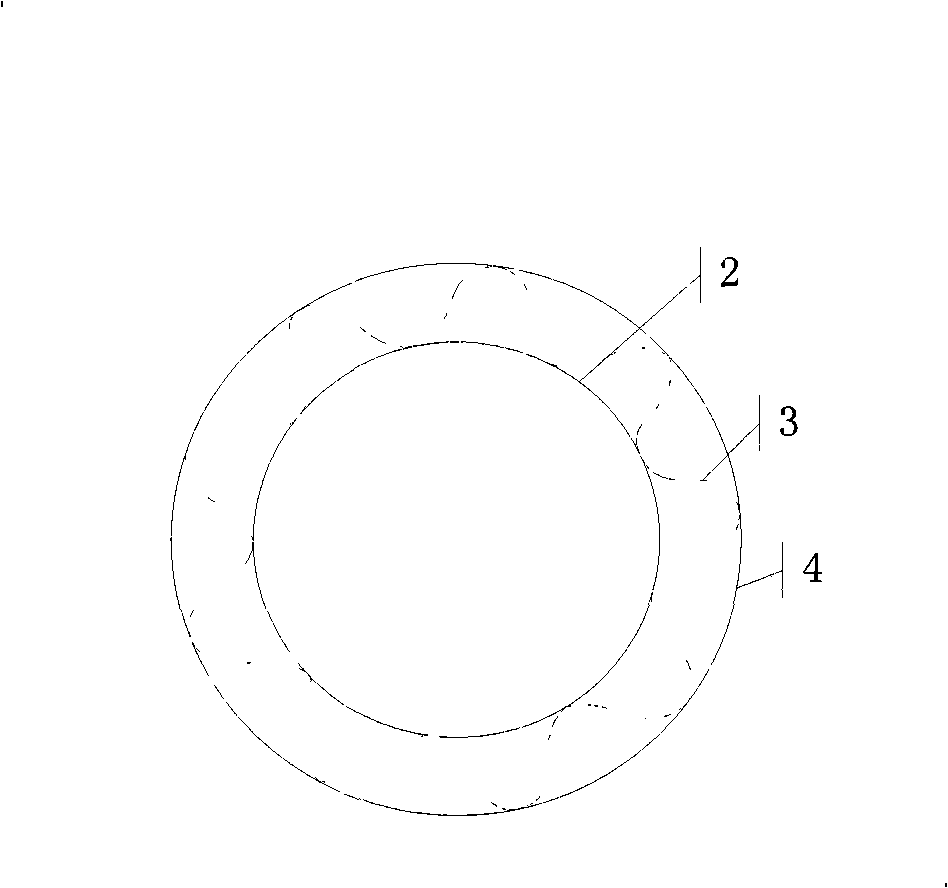

[0011] In the present invention, a layer of elastic support grid is respectively attached to the upper and lower sides of the plate filter membrane, which is folded into an arc-shaped folded filter membrane 3 by a folding machine, and then the two ends of the folded filter membrane are glued together to form a cylindrical shape. , the folded filter membrane 3 is fixed with the inner stainless steel mesh 2 and the outer stainless steel mesh 4, and finally the top and bottom ends of the cylindrical folded filter membrane 3 are sealed and fixed with the filter element fixed head 1, as shown in Figure 1 The cylindrical pleated filter element shown. If it is normal temperature water filtration, use glass mesh as the support grid; if the water temperature is higher than 30 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com