Diesel engine cylinder cover slant hole processing device

A processing device and cylinder head technology, which is applied to metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve problems such as inability to guarantee the machining accuracy of the inclination angle of inclined holes, high manufacturing accuracy requirements, and difficulty in measuring inclined holes. Improve repeat positioning accuracy, facilitate precise processing, avoid offset and vibration effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

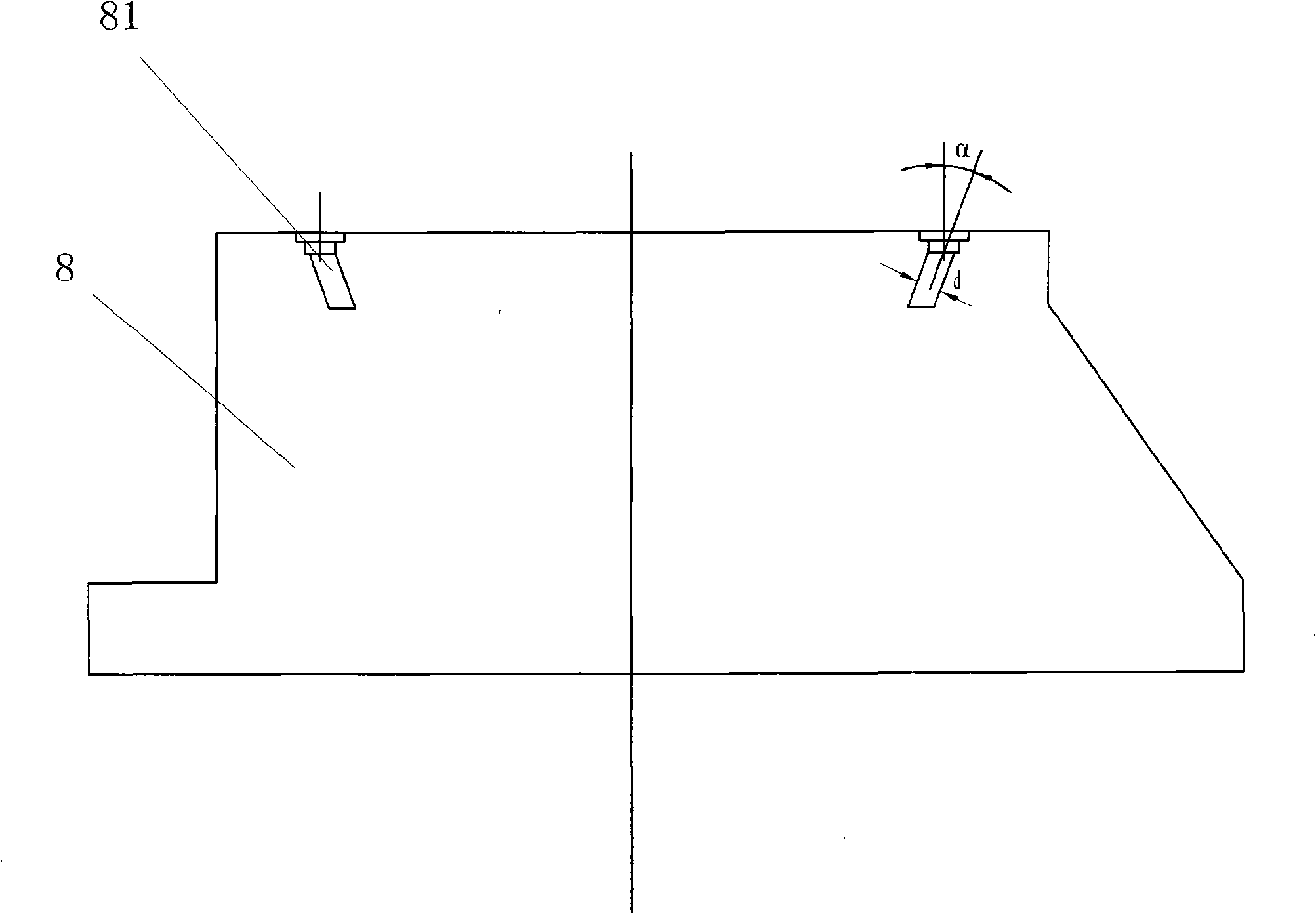

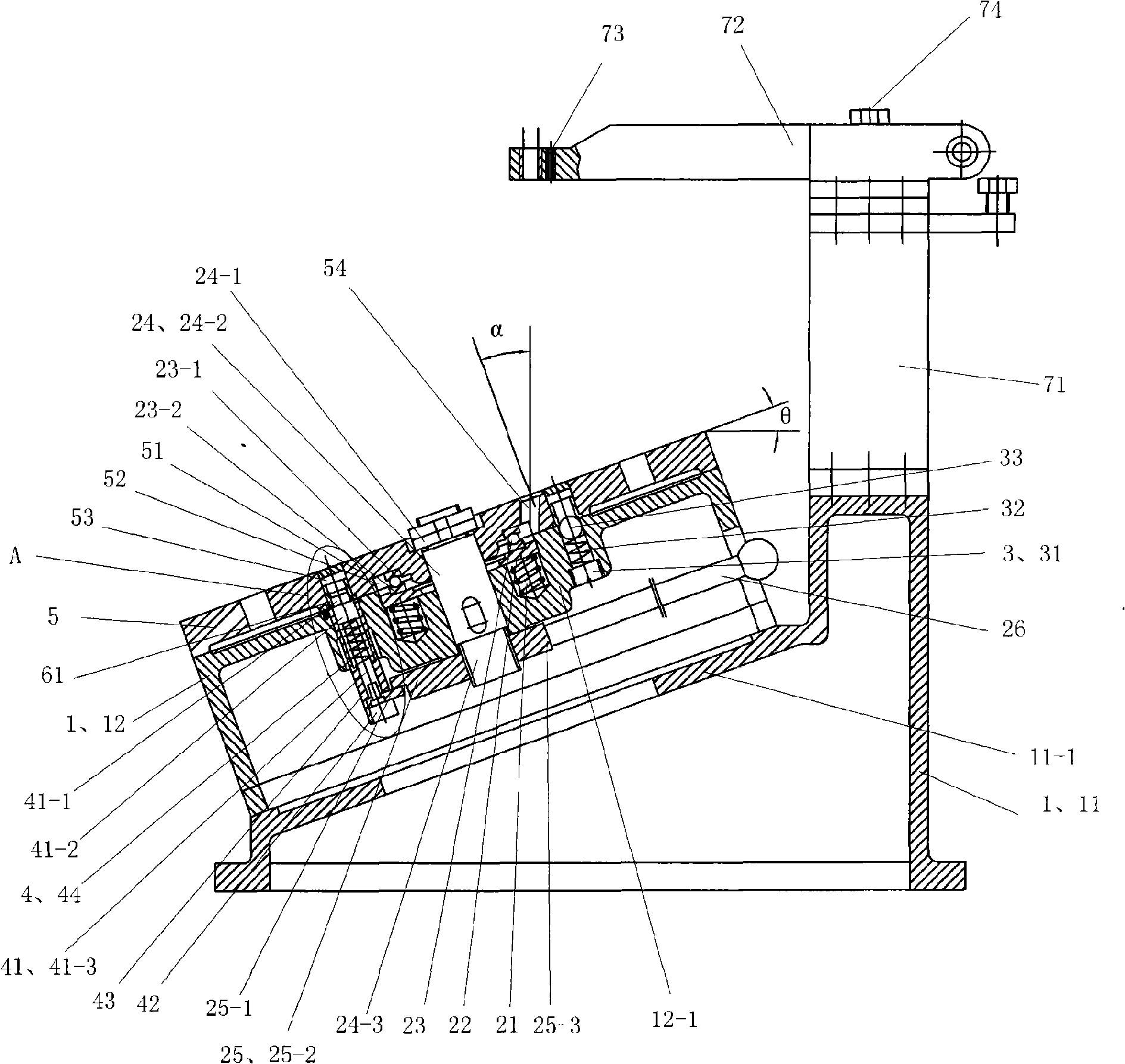

[0014] See Figure 2 to Figure 5 , Diesel engine cylinder head oblique hole processing device of the present invention has a processing table 1 and a rotary indexing plate 5 .

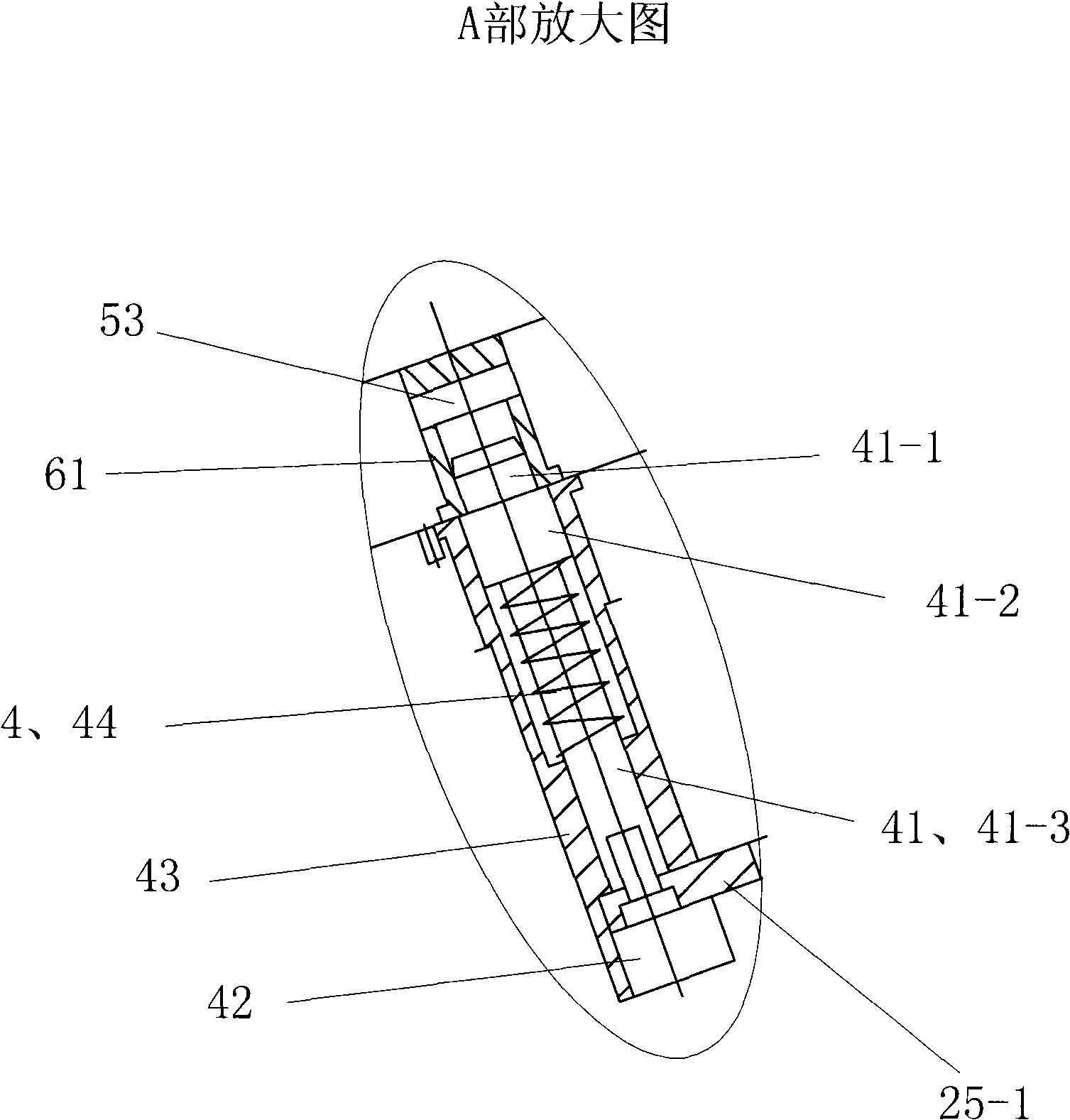

[0015] The processing table 1 includes a base 11 and a rotary support 12 . The base 11 has an oblique rotary support fixing plate 11 - 1 , and the rotary support 12 is fixed on the rotary support fixing plate 11 - 1 of the base 11 . The central mounting part 12-1 of the slewing support 12 is provided with a central hole located in the center and an annular seat cavity for springs with an opening around the central hole facing upward in the axial direction, and a positioning position located outside the annular seat cavity for the springs. The pin hole and the positioning member hole are arranged symmetrically with respect to the axis of the central hole of the slewing support 12 .

[0016] The rotary index plate 5 is provided with a connecting seat portion 51 located in the center, and the connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com