Fastening forming method and special fastening machine thereof

A molding method and buckle machine technology, applied to other household appliances, applications, household appliances, etc., can solve problems such as complex structure, buckle falling off force and position, and irregular change of aluminum buckle shape, so as to simplify the transmission mechanism, The effect of improving work efficiency and simplifying the push button process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings, but they are not intended to limit the present invention.

[0036] The buckle forming method in this embodiment includes the processes of wire feeding, cutting, forming, sealing, and film cutting, which also includes:

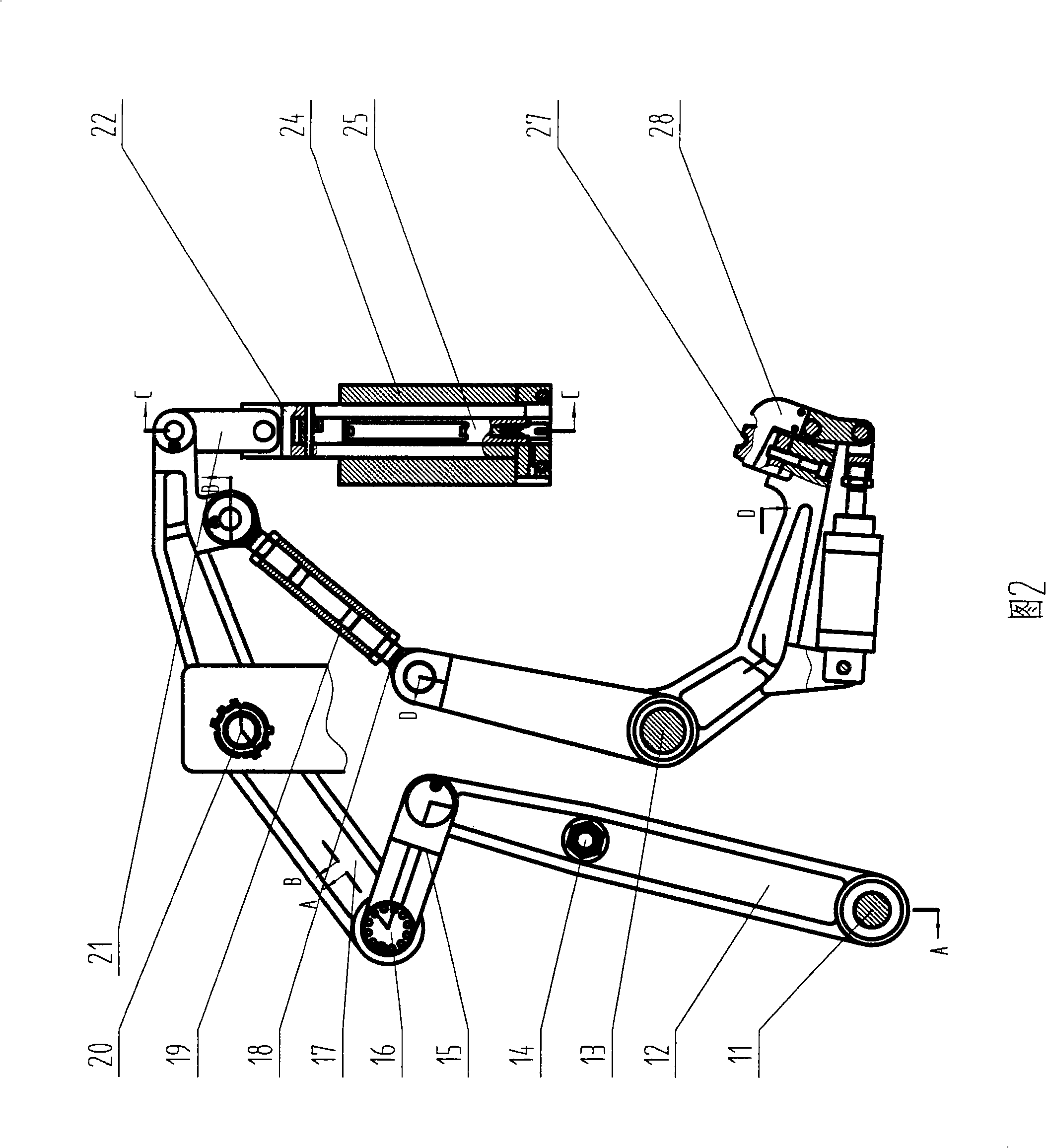

[0037] A. A cam mechanism and a connecting rod mechanism are used to drive sequentially to complete the clamping, stretching, loosening, and stretching mechanism reset actions;

[0038] B. Using another cam mechanism together with the connecting rod mechanism to drive sequentially to complete the buckle forming process in the card punching mechanism.

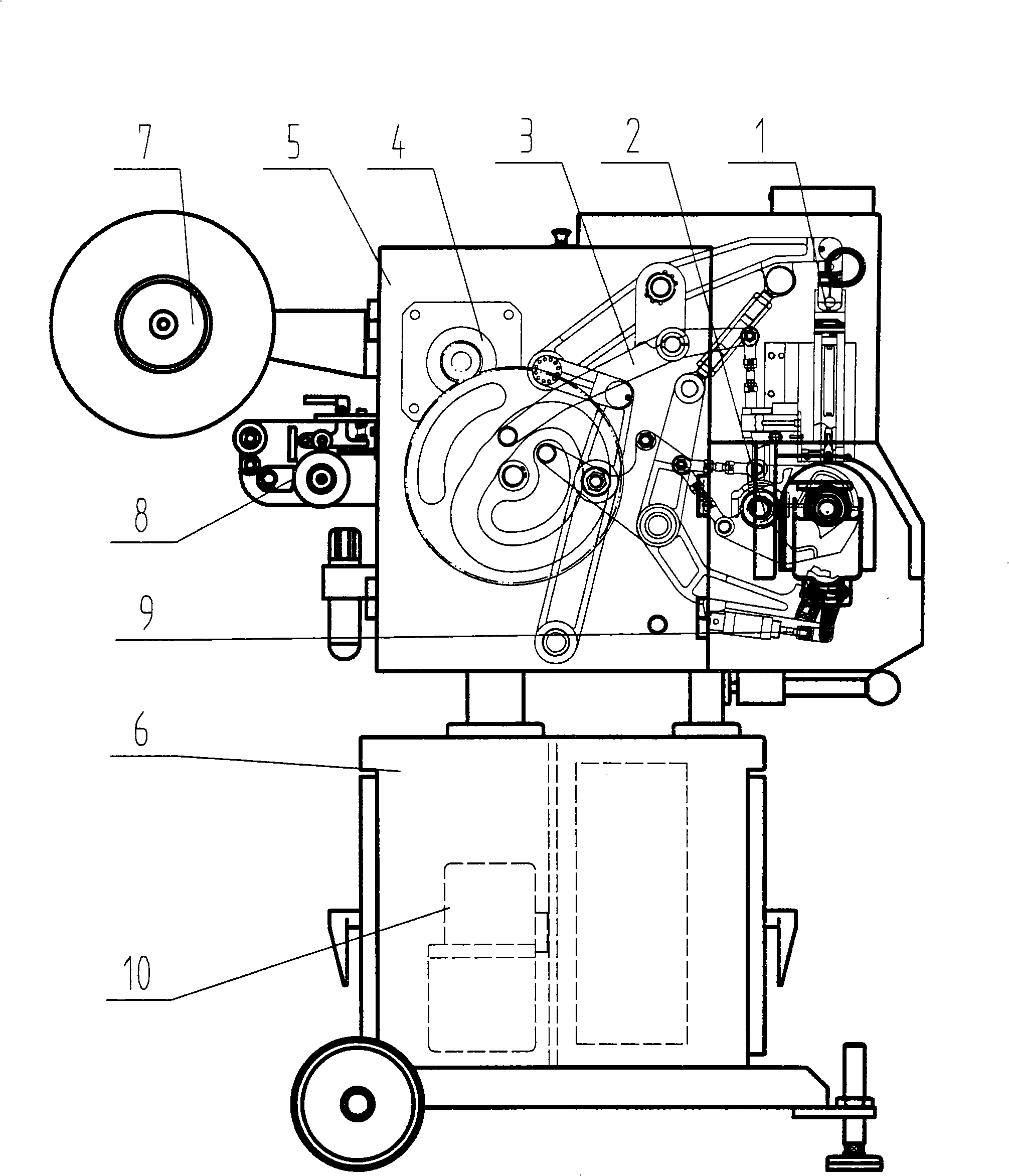

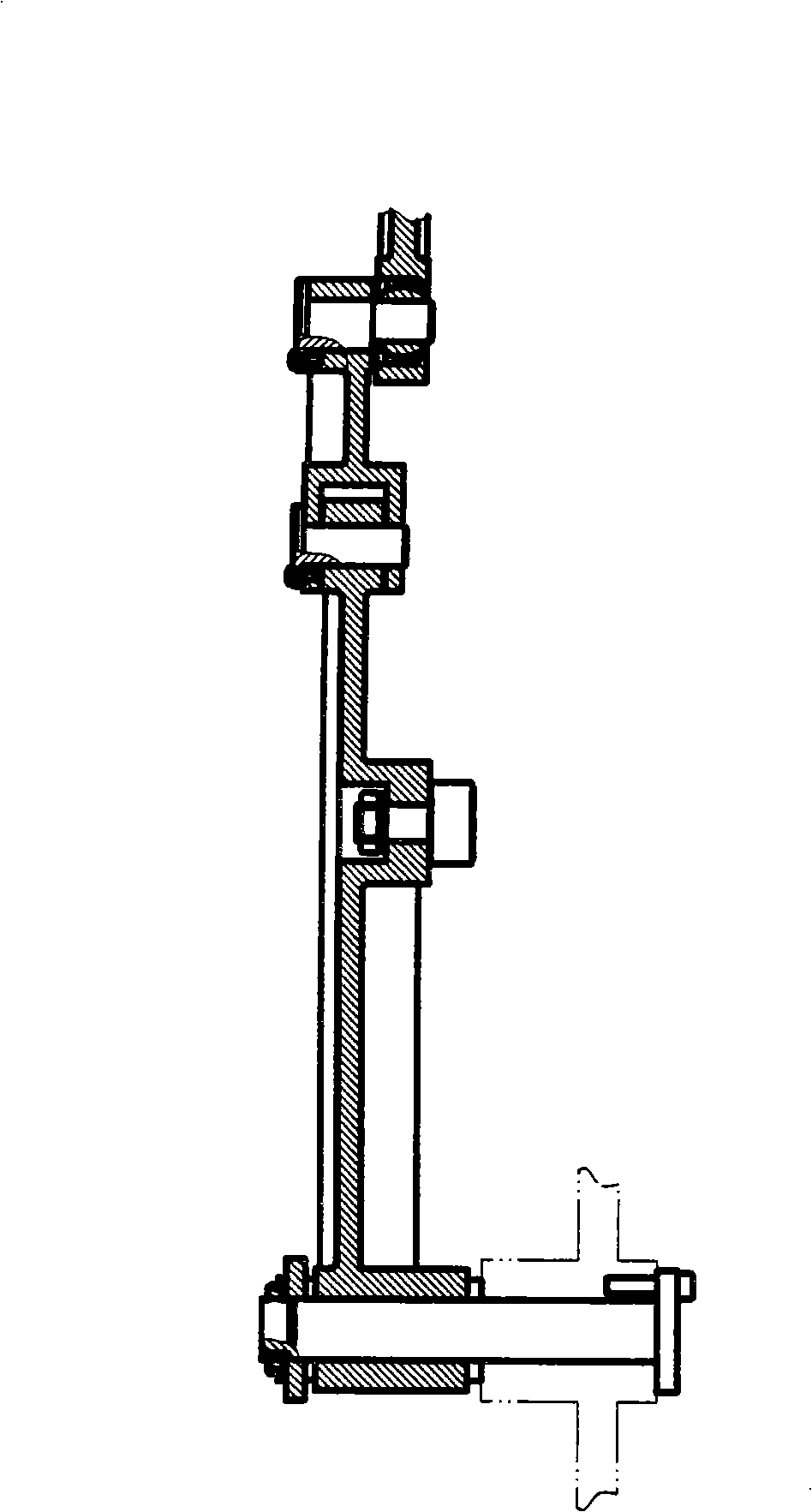

[0039] The special buckle machine for the buckle forming method in this embodiment includes a clamping mechanism 2, a stretching mechanism 3, a punching mechanism 1, a wire feeding mechanism 8, a pneumatic cutting mechanism 9, a lubricating mechanism 10, a power source and a transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com