Oxidative degradation process for high concentrated organic wastewater by microwave cooperating with ferrate catalyst

A technology for organic wastewater, oxidative degradation, applied in chemical instruments and methods, oxidized water/sewage treatment, water/sewage multi-stage treatment, etc. Oxidative degradation rate, excellent adsorption capacity, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

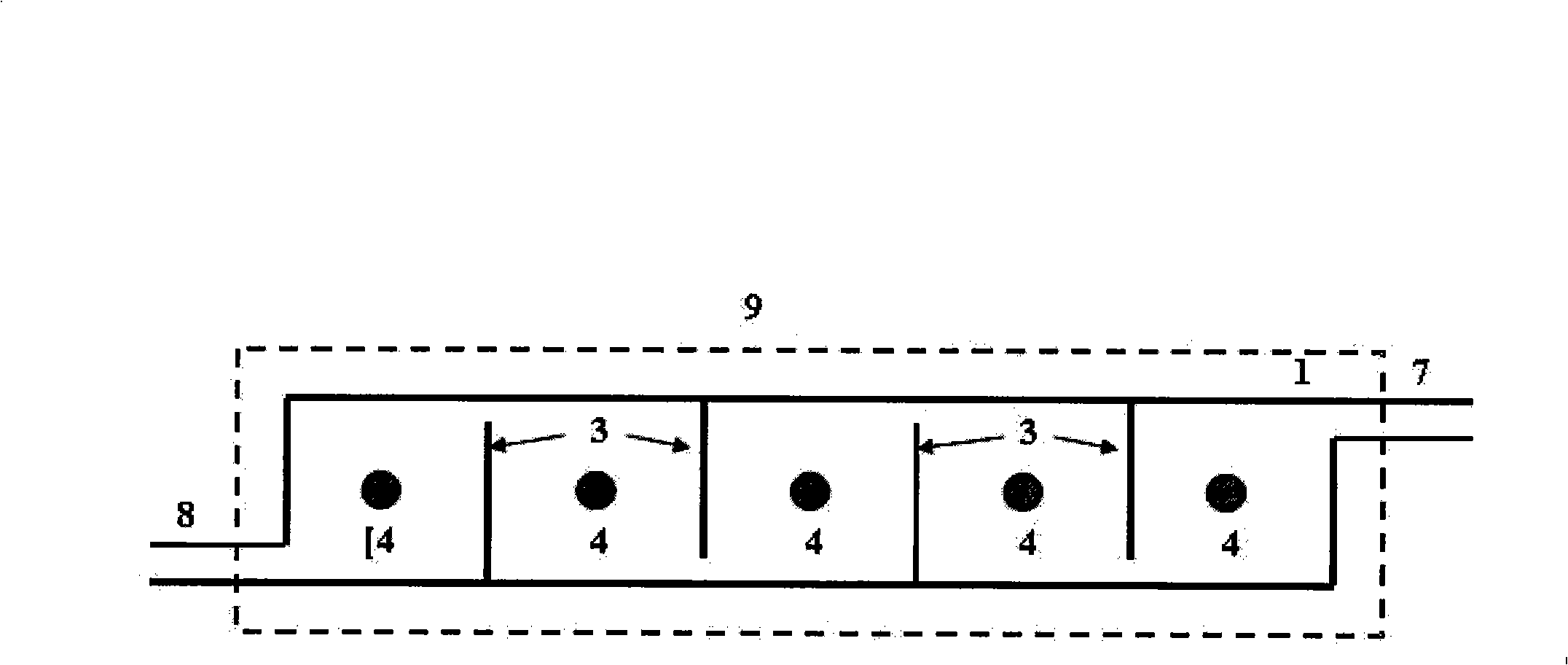

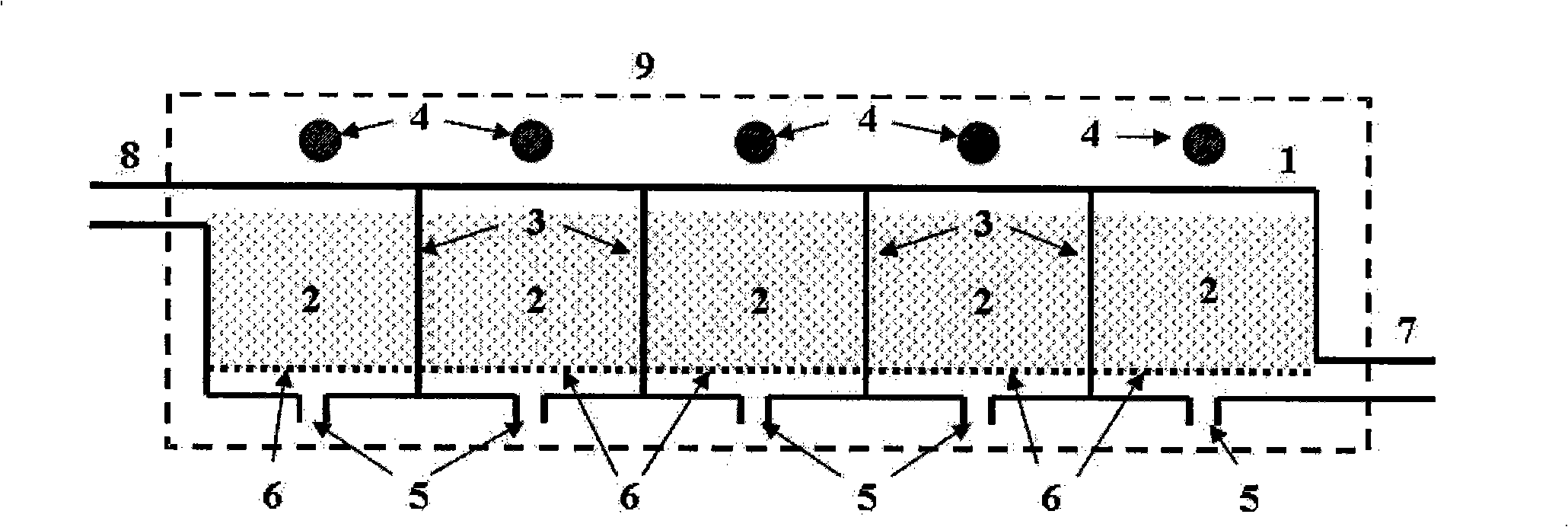

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: the treatment of printing and dyeing wastewater

[0022] Take reactive brilliant red dye wastewater from a printing and dyeing factory, the initial CODc of wastewater r 140mg / L, chromaticity 1200 times, first adjust the pH value of wastewater to 7.0 with calcium hydroxide, remove suspended particles by natural sedimentation, pump into the microwave reaction tank with catalyst manganese ferrite, the amount of manganese ferrite is 10% by weight, and pass into the ozone of 0.001% of the waste water weight, start the microwave launch tube at the same time, the microwave tube is intermittently 0.5 minutes after every 0.5 minutes of opening, and the residence time of the control waste water in the reaction tank is controlled at 30 seconds, and the decolorization rate of the effluent is 100%, COD Cr The removal rate is 85%, and the treated wastewater meets the national discharge standards.

Embodiment 2

[0023] Embodiment 2: Tannery wastewater treatment

[0024] Taking the tannery wastewater from a tannery enterprise, its initial CODc r 4070mg / L, adjust the pH value of the wastewater to 10.0 with calcium carbonate, add 0.1ppm polyacrylamide to flocculate and settle to remove suspended particles, pump it into the microwave reaction tank where the catalyst cobalt ferrite is placed, the amount of cobalt ferrite is the weight of wastewater 0.5% of the waste water, and 0.08% of the weight of the waste water is introduced into the air, and the microwave emission tube is started at the same time. The microwave tube is turned on for 1.5 minutes and then intermittently for 1.5 minutes. The residence time of the waste water in the reaction tank is controlled at 30 minutes, and the effluent COD Cr The removal rate is 90%.

Embodiment 3

[0025] Embodiment 3: papermaking wastewater treatment

[0026] Wastewater from a paper mill, pH=13 before treatment, CODc r It is 2860mg / L, no need to adjust the pH value, add 1ppm polyacrylamide to flocculate and settle to remove suspended particles, pump it into the microwave reaction tank where the catalyst nickel ferrite is placed, the amount of nickel ferrite is 1% of the weight of the wastewater, and pass it into Pure oxygen with 0.005% of the waste water weight, start the microwave emission tube at the same time, the microwave tube is turned on for 1 minute and then pause for 1 minute, control the residence time of the waste water in the reaction tank to 20 minutes, and the effluent COD Cr The removal rate is 80%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap