Single-phase pipeline shielding electric pump

A technology of shielding electric pumps and shielding motors, which is applied in the directions of pumps, pump devices, pump components, etc., achieves the effects of reliable operation, simple assembly and reduction of raw material costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

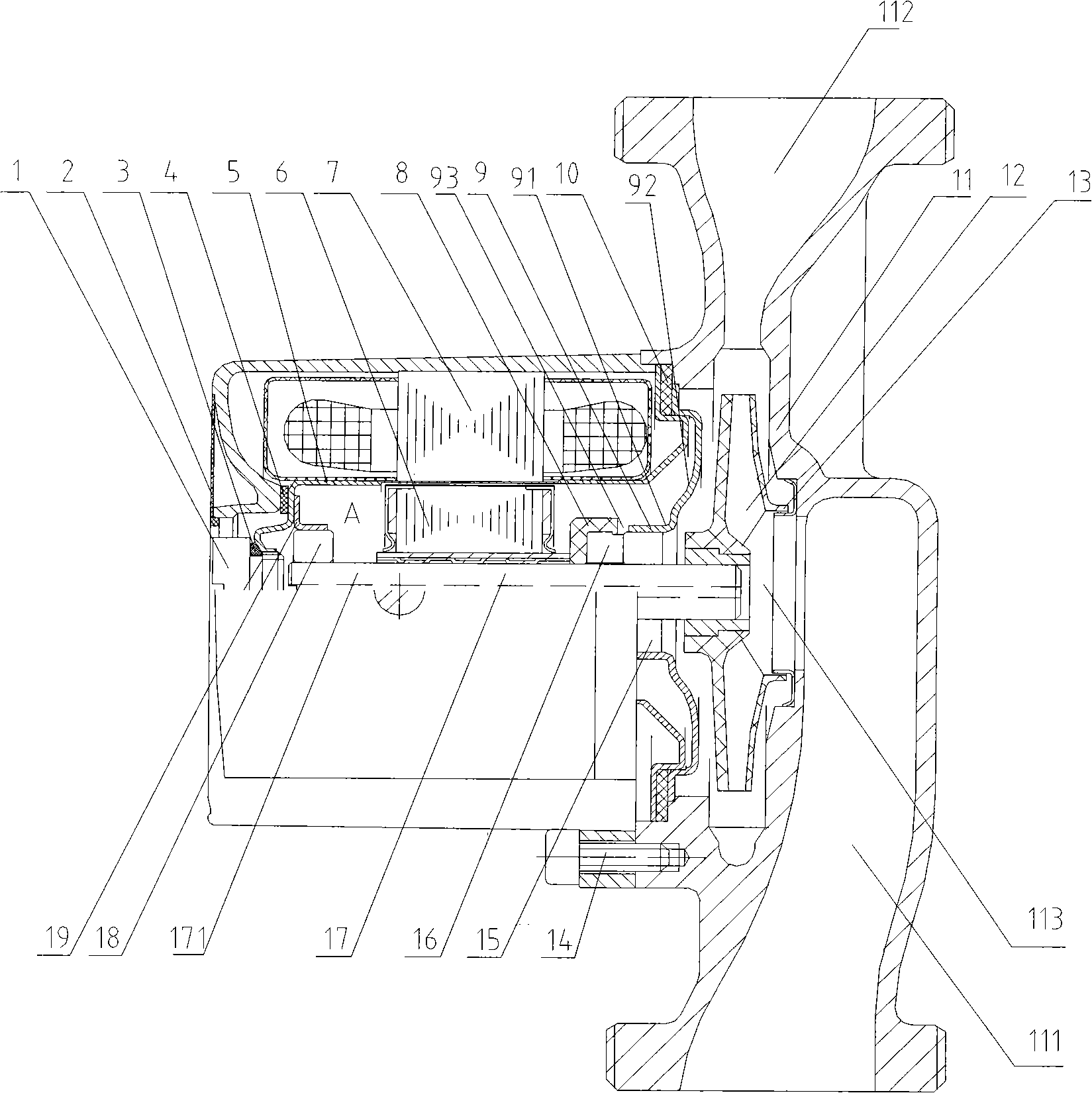

[0014] The structure and working principle of the present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

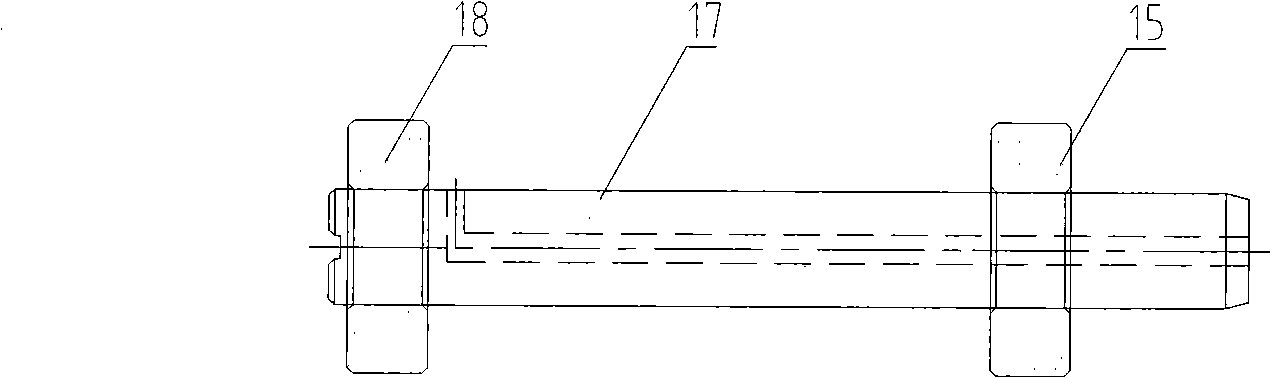

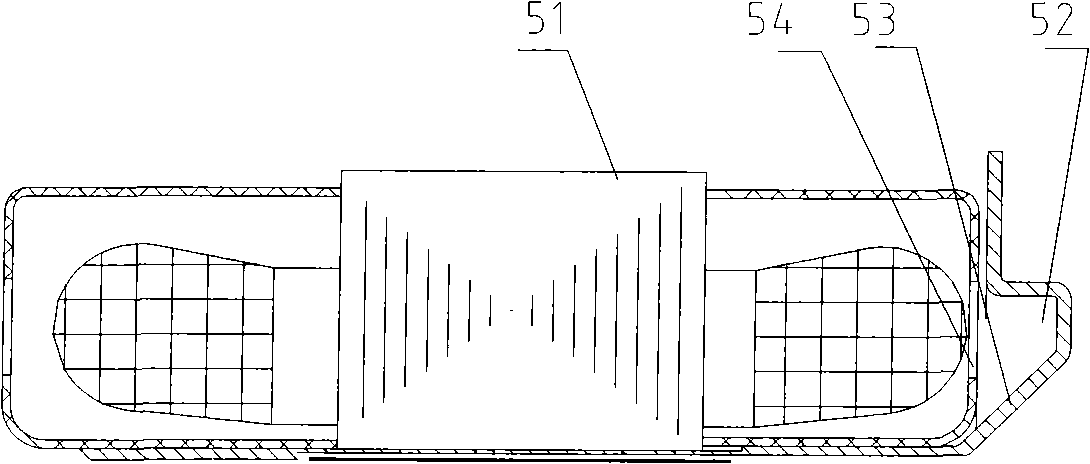

[0015] Such as figure 1 with figure 2 As shown, the single-phase pipeline shielded electric pump includes a pump body 11, an impeller 12 and a shielded motor part. The pump body 11 is provided with inlet and outlet channels 111 and 112 and an impeller chamber 113, and the impeller chamber 113 connects the inlet and outlet channels 111 and 112. The shielded motor part includes motor housing 2, deflation screw 1, sealing ring 3, upper gasket 4, shielding sleeve 5, rotor 6, stator 7, thrust bearing seat 8, lower bearing seat 9, lower gasket 10, impeller 12 , mouth ring 13, lower bearing 15, thrust bearing 16, rotating shaft 17, upper bearing 18, upper bearing seat 19.

[0016] There are three steps at the position where the pump body 11 is used to install the motor casing 2, the shielding sleeve 5 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com