Ultra-high hydraulic double-acting mechanical locking oil cylinder

A mechanical locking, double-acting technology, applied in the direction of fluid pressure actuation device, etc., can solve the problems of uncontrollable speed, affecting the construction progress, slow return speed, etc., to achieve controllable speed, easy layout, and less overall height increase Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

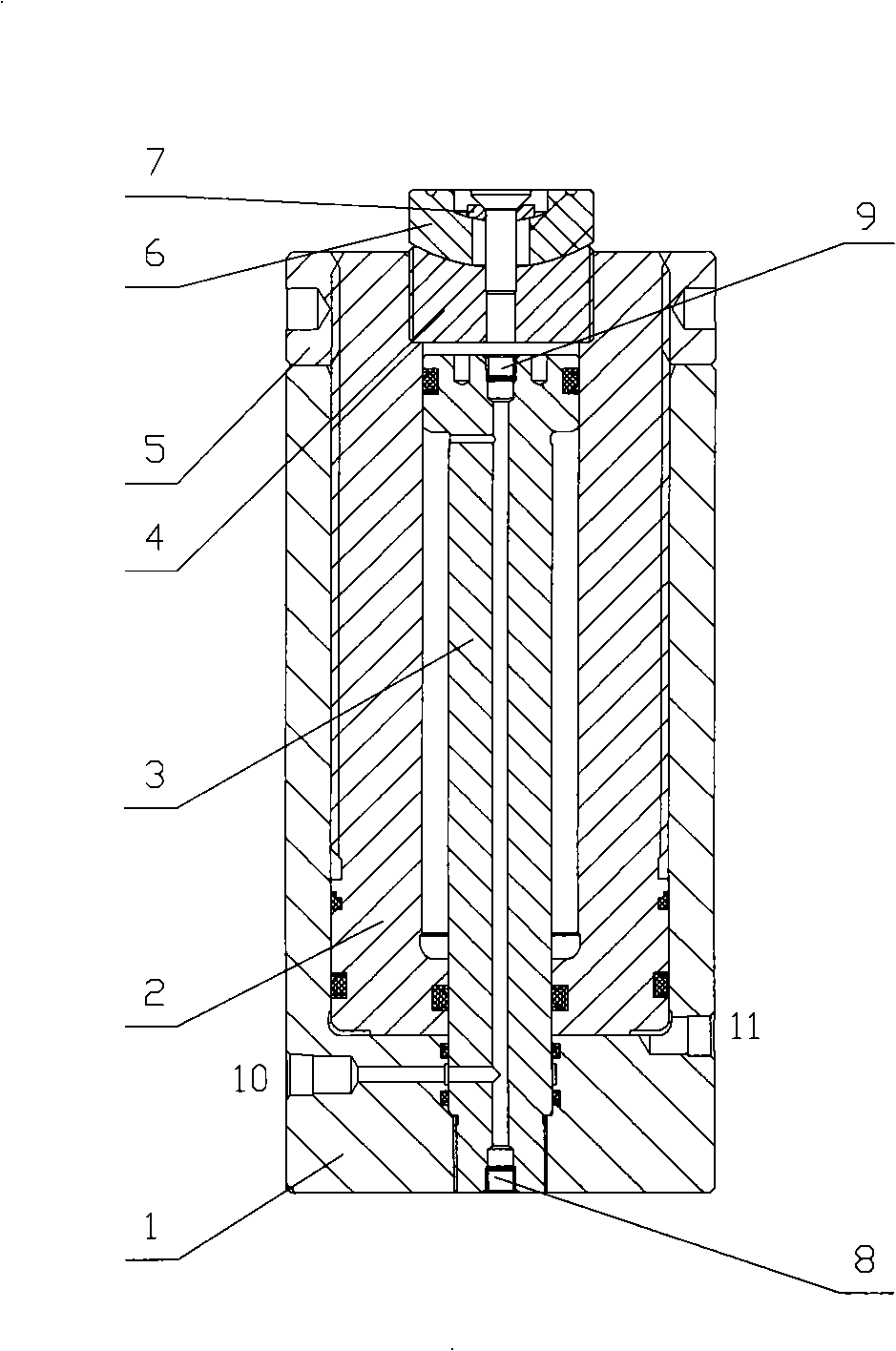

[0015] As shown in Figure 1, it is a schematic structural diagram of an ultra-high hydraulic double-acting mechanical locking oil cylinder. The described ultra-high hydraulic double-acting mechanical locking oil cylinder consists of an oil cylinder barrel 1, a threaded piston rod inner cylinder barrel 2, a hollow Inner guide column 3, spherical top plate seat 4, lock nut 5, spherical top plate 6, spherical gasket 7, lower plug 8, upper plug 9, first oil inlet 10 and second oil inlet 11 .

[0016] The threaded piston rod inner cylinder 2 is installed in the oil cylinder 1, and the lock nut 5 is installed on the upper side of the threaded piston rod inner cylinder 2, and the first oil inlet 10 and the second oil inlet 10 are respectively arranged on both sides of the oil cylinder 1. The second oil inlet 11, the hollow inner guide post 3 is installed in the threaded piston rod inner cylinder 2, the oil cylinder cylinder 1, the threaded piston rod inner cylinder 2 and the hollow i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com