Hydraulic automobile transmission differential mechanism

A differential mechanism and automobile technology, applied in the direction of liquid fuel engines, transmissions, differential transmissions, etc., can solve the problems of unfavorable automobile miniaturization, complex structure, and large volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

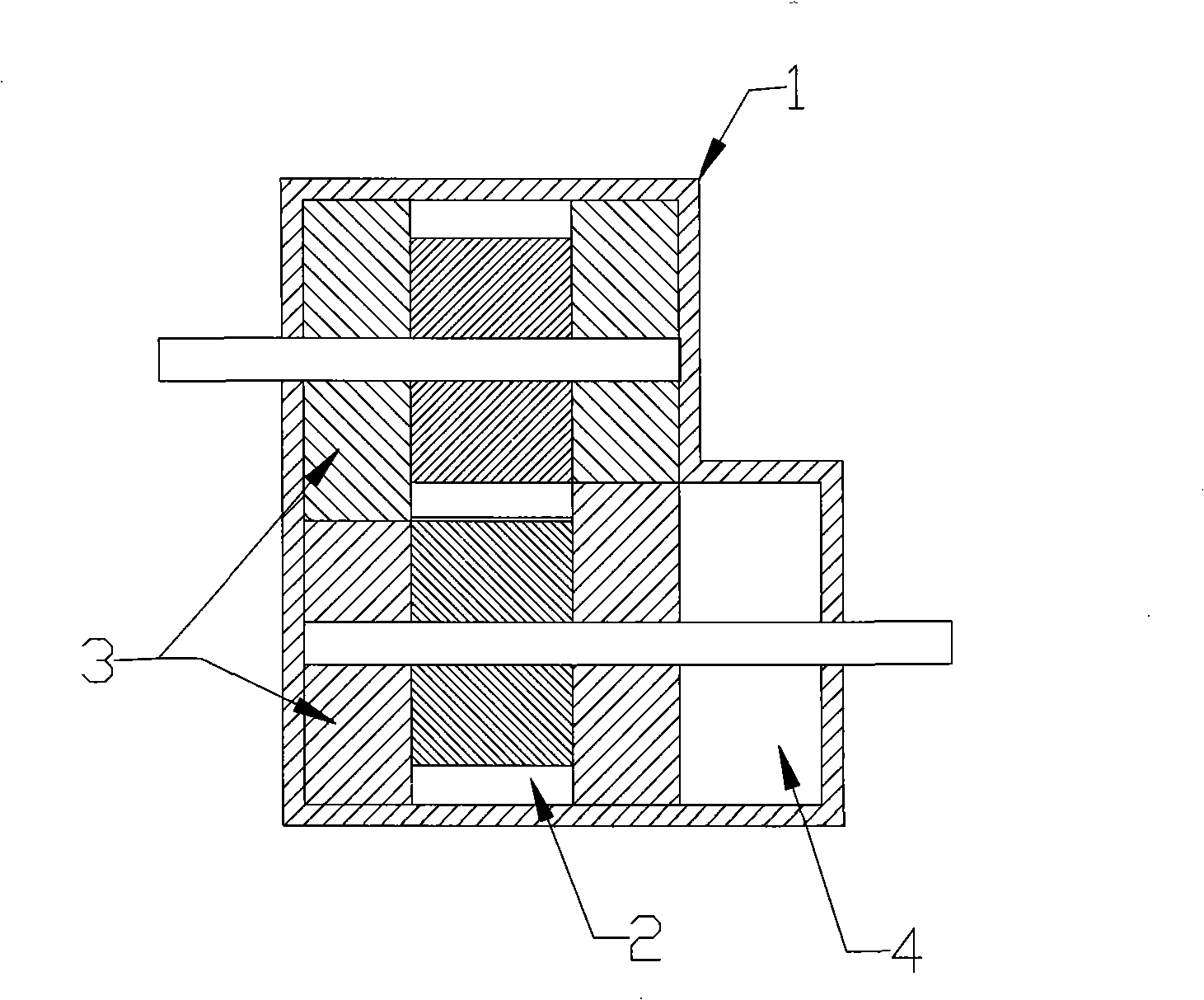

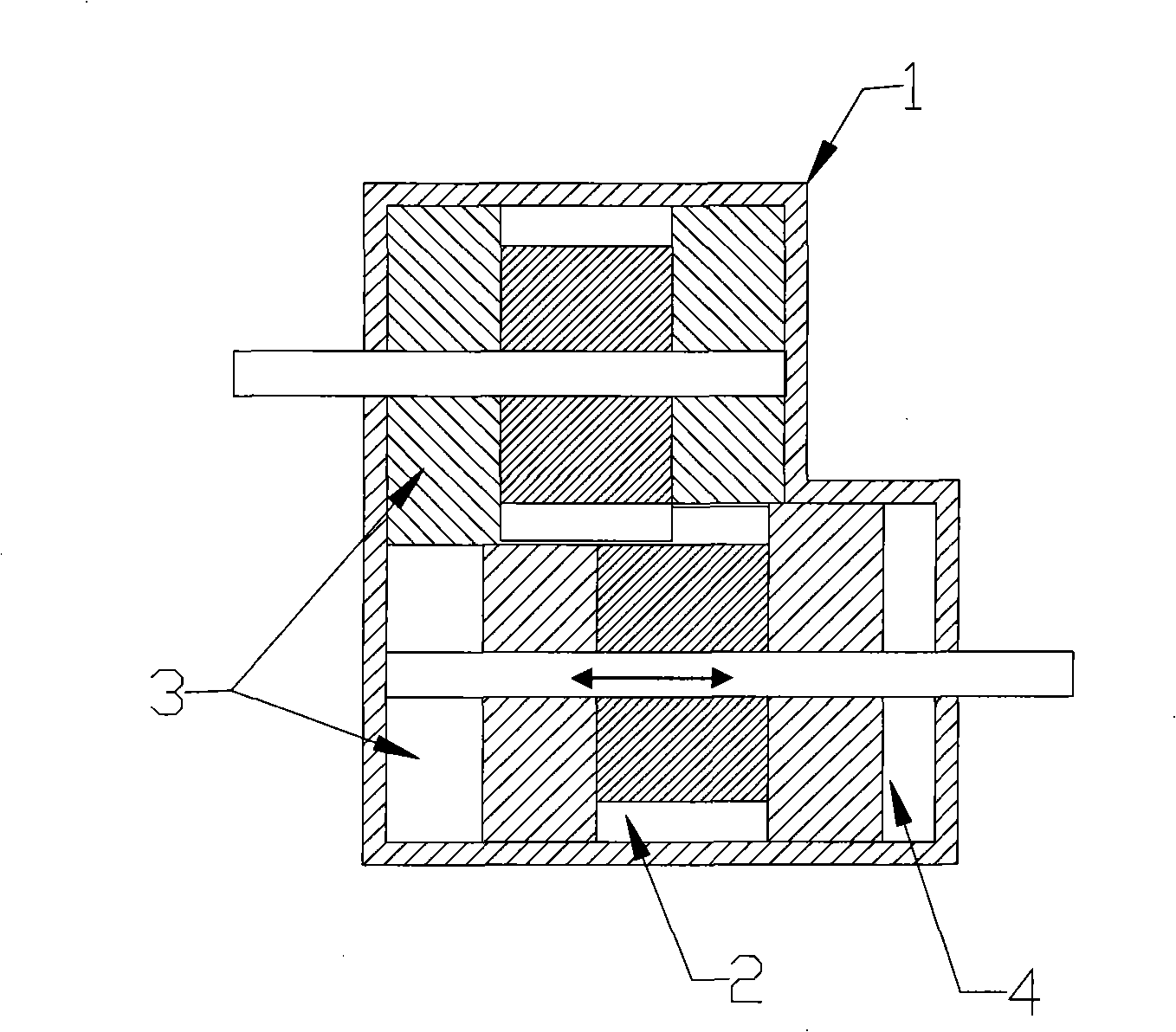

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

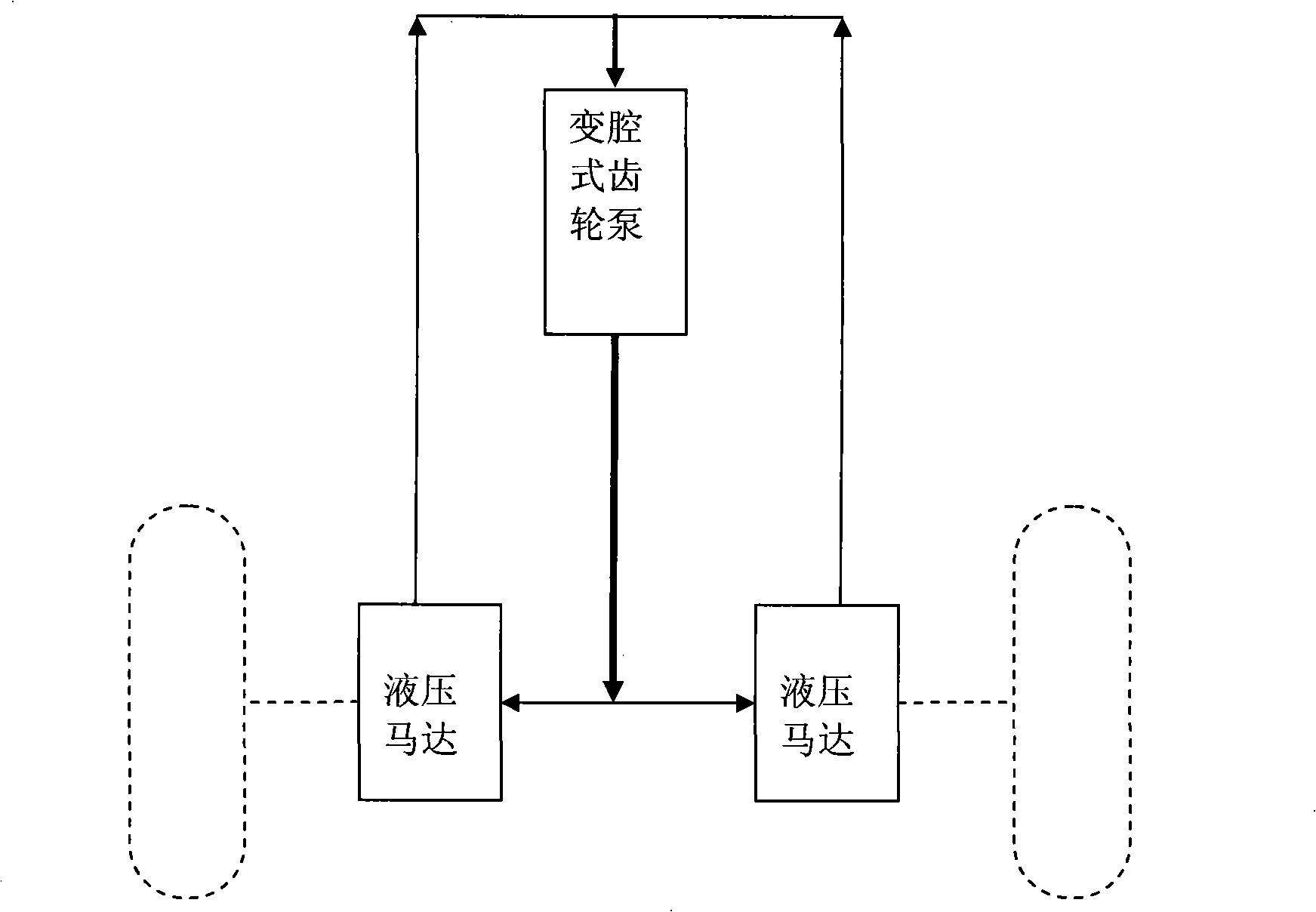

[0023] Such as figure 1 As shown, the hydraulic vehicle transmission and the differential mechanism of the present invention comprise a variable chamber gear pump and two hydraulic motors connected with the half shaft, wherein the liquid outlet of the variable chamber gear pump is connected to the two hydraulic motors The liquid inlets are connected through pipelines, and the liquid outlets of the two hydraulic motors are connected with the liquid inlets of the variable cavity gear pump through pipelines to form two driving oil circuits.

[0024] Among them, the above-mentioned variable cavity gear pump has the characteristics of stepless output power without the need for relief valves or other pressure limiting valves; through the variable cavity gear pump, the power output by the engine can be driven through the pipeline to drive the hydraulic motor t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com