Three-way ball valve

A three-way ball valve and valve body technology, applied in the field of machinery, can solve problems such as single function and difficult to achieve, and achieve the effect of simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

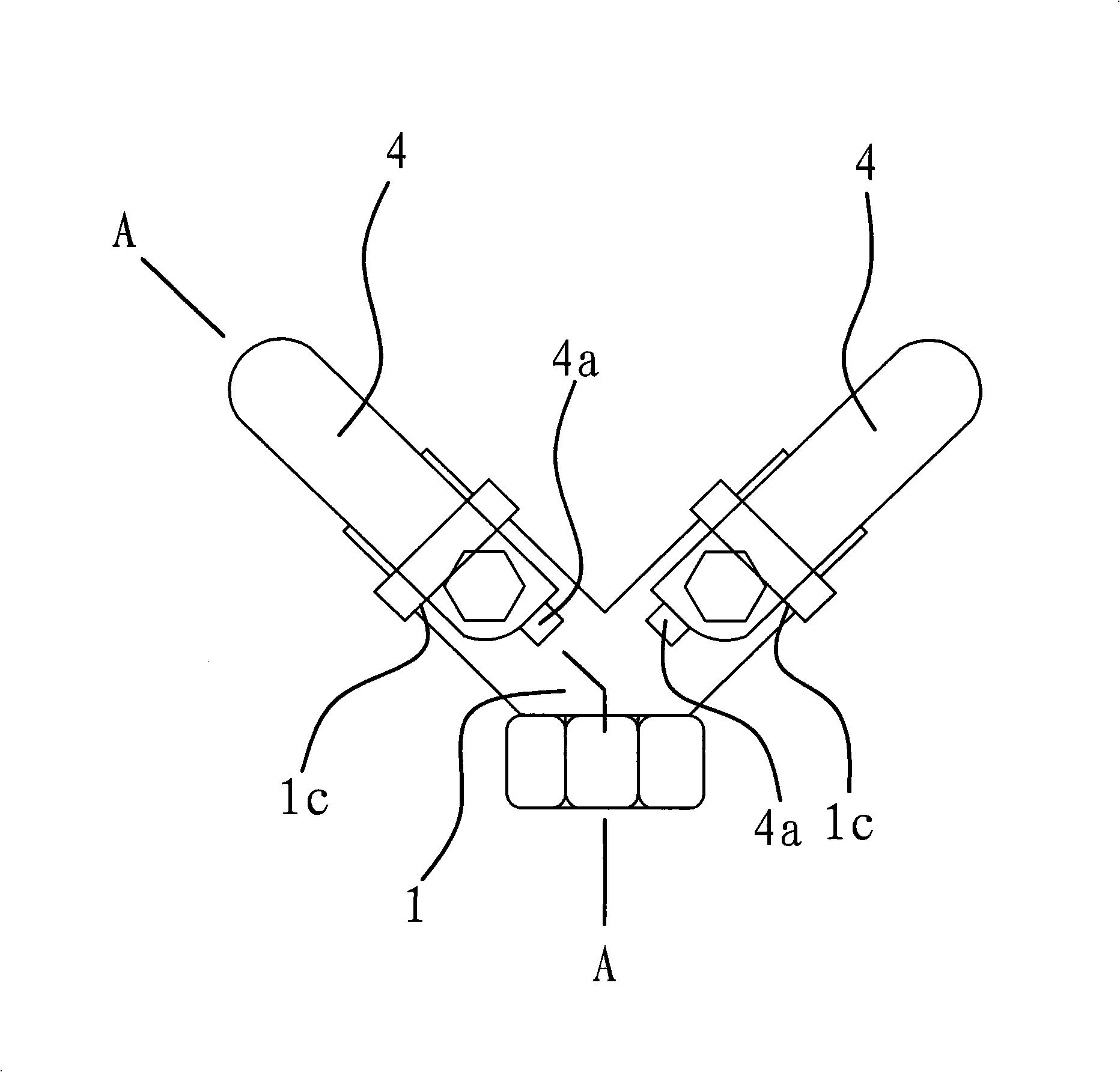

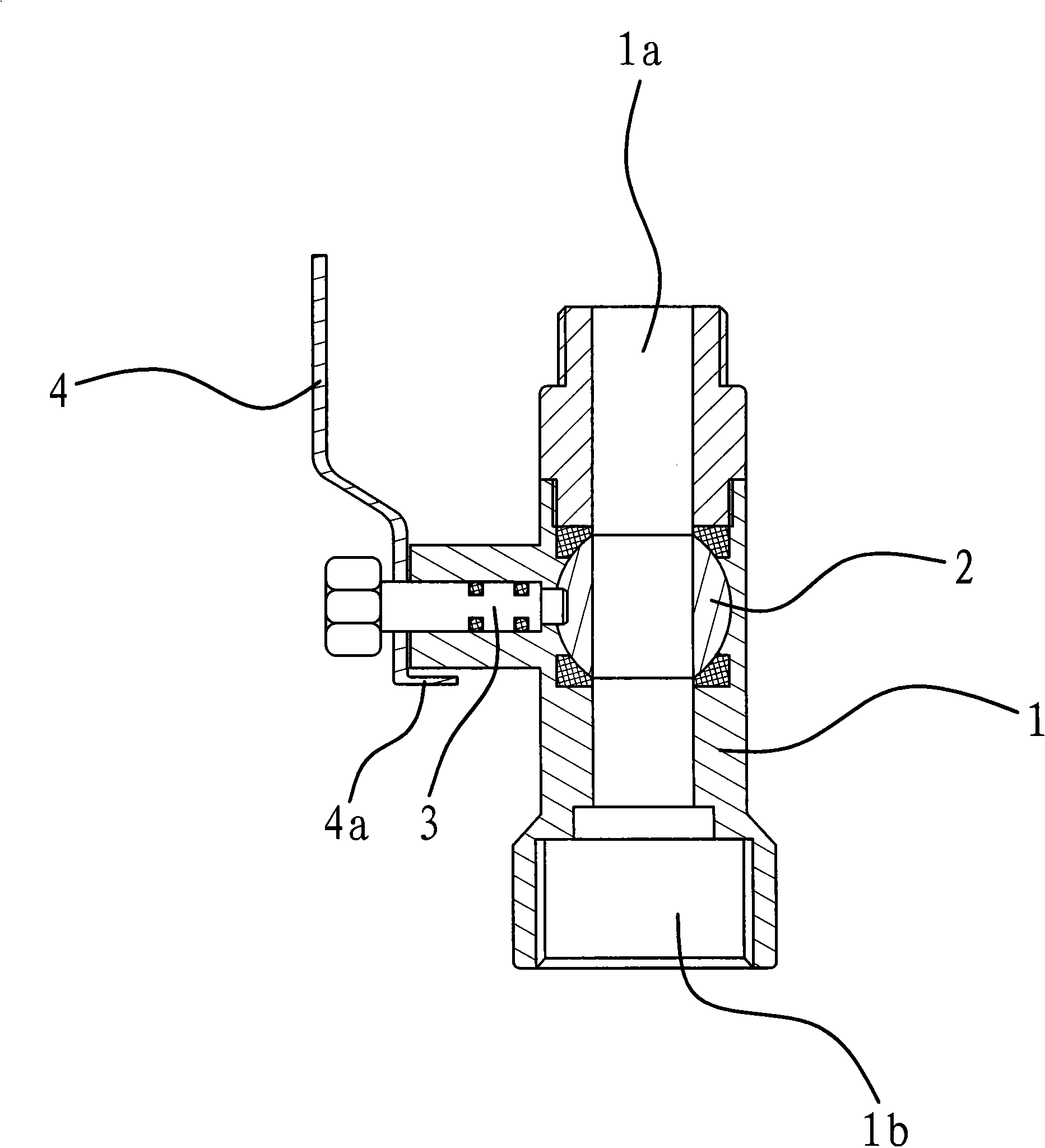

[0021] As shown in Figure 1, the three-way ball valve includes a valve body 1, a valve core 2, a valve stem 3 and a handle 4. The interior of the valve body 1 is a cavity, that is to say, the valve body 1 has two water inlet channels 1a and A water outlet channel 1b.

[0022] The two water inlet channels 1a form an L shape, and the inlet end of the water outlet channel 1b communicates with the corners of the L shape of the two water inlet channels 1a.

[0023] As shown in FIG. 1 and FIG. 2 , there are two valve cores 2 , valve stems 3 and handles 4 . One of the valve cores 2 is installed in one of the water inlet channels 1a, the inner end of the valve stem 3 is fixedly connected with the valve core 2, the outer end of the valve stem 3 passes through the valve body 1, and the handle 4 is fixedly connected with the valve stem 3 outer end. The other valve core 2 is installed in another water inlet channel 1a, and the valve stem 3 and the handle 4 are connected in the same way,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com