Optical inspection device

A technology of optical inspection and irradiation of light, applied in the direction of using optical devices, measuring devices, optical radiation measurement, etc., can solve the problems of difficult inspection and reduced productivity, and achieve the effect of high-quality inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

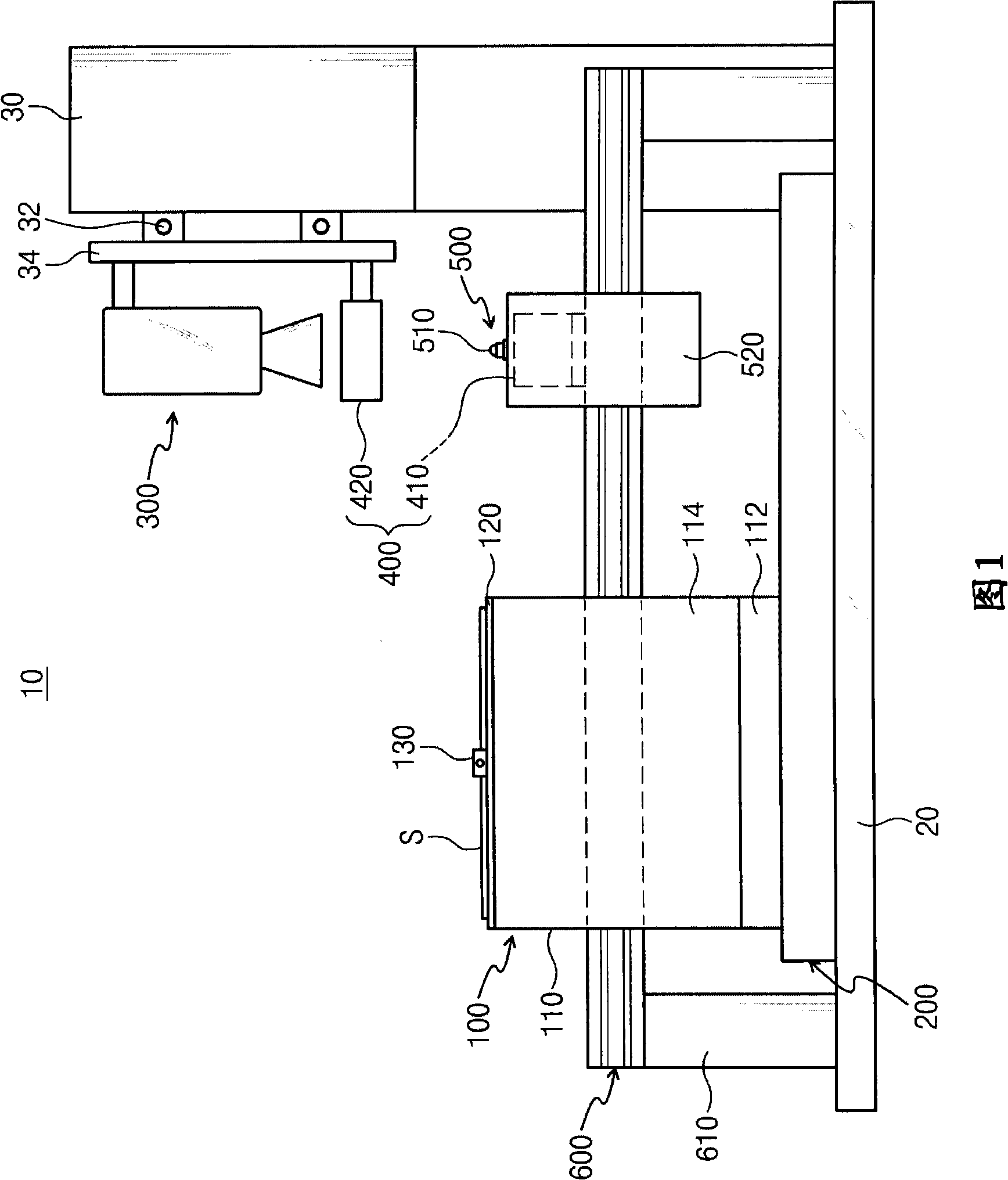

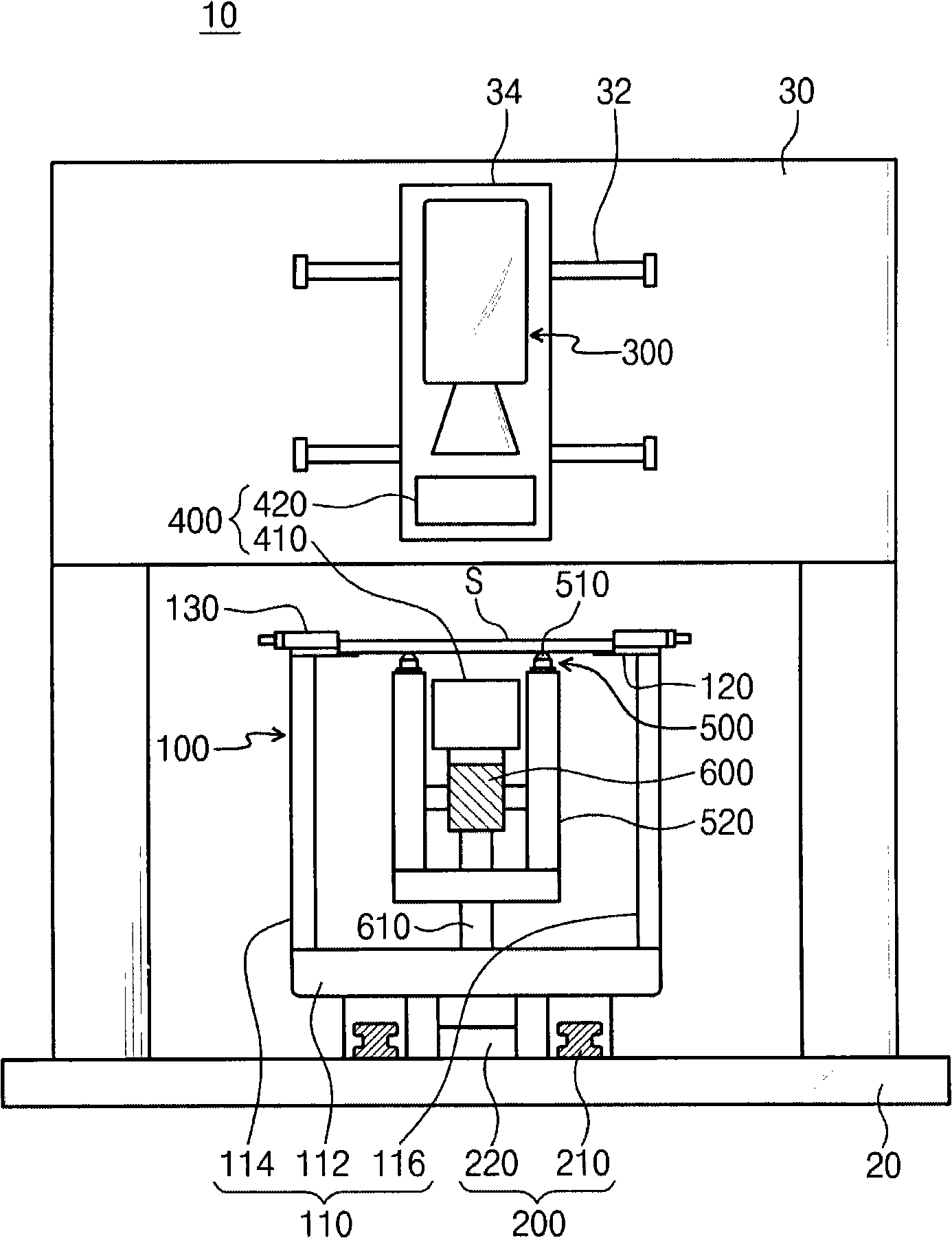

[0042] FIG. 1 is a front view illustrating the structure of an optical inspection device according to a first embodiment of the present invention, figure 2 It is a side view illustrating the structure of the optical inspection device according to the first embodiment of the present invention.

[0043] Referring to Figure 1 and figure 2 , the optical inspection device 10 of the present invention includes a stage 100 , a linear movement unit 200 , an imaging unit 300 , an illumination unit 400 and a rolling member 500 .

[0044] Stage

[0045] The stage 100 includes a body 110 having a bottom surface 112 , a first side 114 and a second side 116 . On the upper layer of the fuselage 110 , that is, on the upper layer of the first side 114 and the second side 116 , a bracket 120 and a positioning member 130 are provided. The inspection object S is placed in a state where both side edges are supported on the stand 120 . The positioning member 130 is a cylindrical body for posit...

no. 2 approach

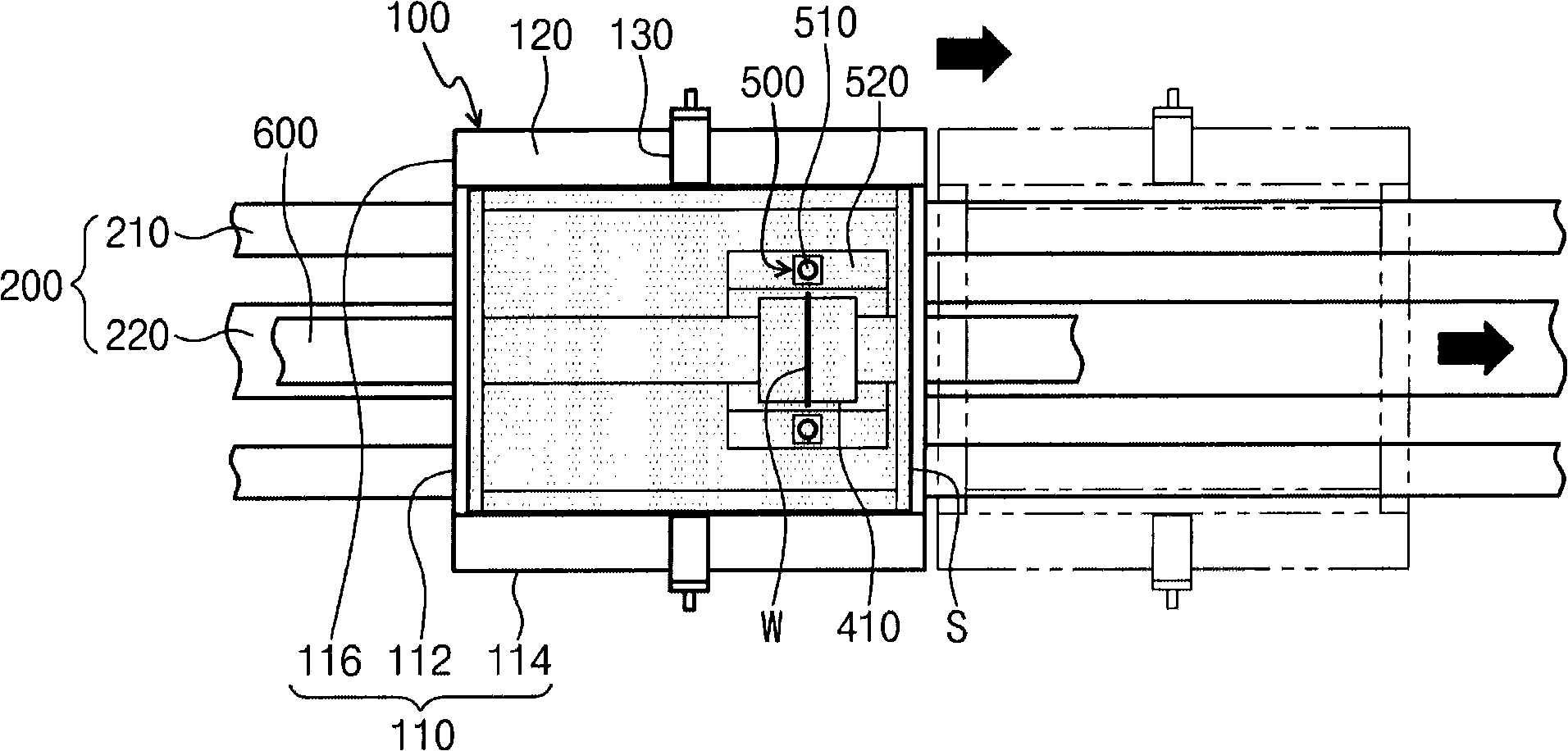

[0060] 5 is a front view for explaining the structure of an optical inspection device according to a second embodiment of the present invention, Figure 6 It is a side view for explaining the structure of the optical inspection apparatus of 2nd Embodiment of this invention.

[0061] Unlike the first embodiment in which the imaging unit, the lighting unit, and the rolling member are fixed, and only the stage is moved to inspect the inspection object, in the second embodiment, the imaging unit and the lighting unit are fixed. The rolling member moves together with the stage, and the inspection object is inspected simultaneously.

[0062] Referring to Figure 5 and Figure 6 , The optical inspection device 10a of the present invention includes a stage 100a, a linear movement unit 200a, a photographing unit 300a, an illumination unit 400a, a rolling member 500a, and the like.

[0063] The stage 100a includes a body 110 having a bottom 112 , a first side 114 and a second side 116 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com