Battery formed acid loop method of lead acid battery

A technology of battery formation and acid cycle, which is applied in the direction of lead-acid batteries, lead-acid battery construction, battery pack components, etc., and can solve problems such as limited volume of the inner cavity of the battery tank, inability to meet the requirements of acid quantity, and long formation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

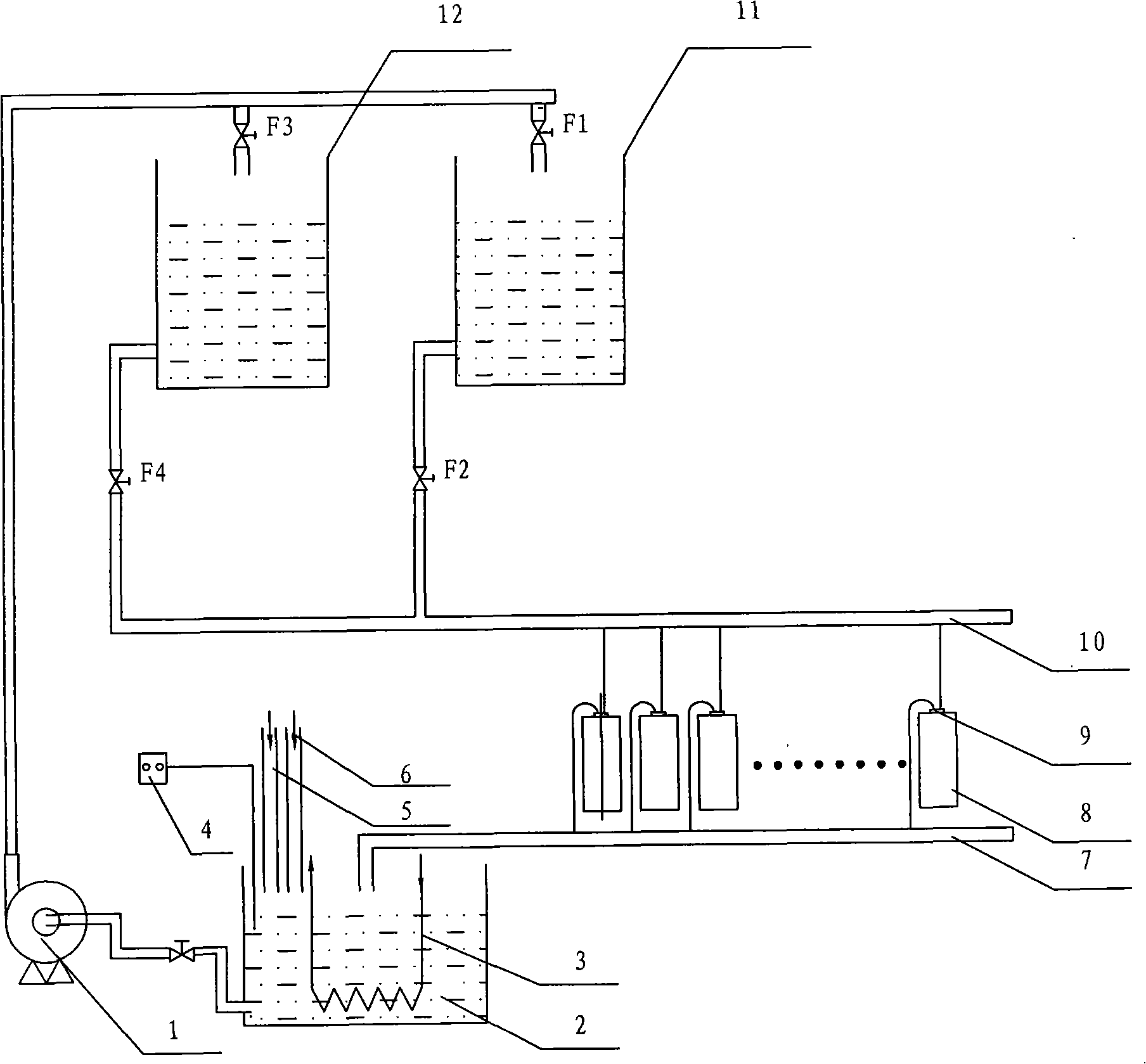

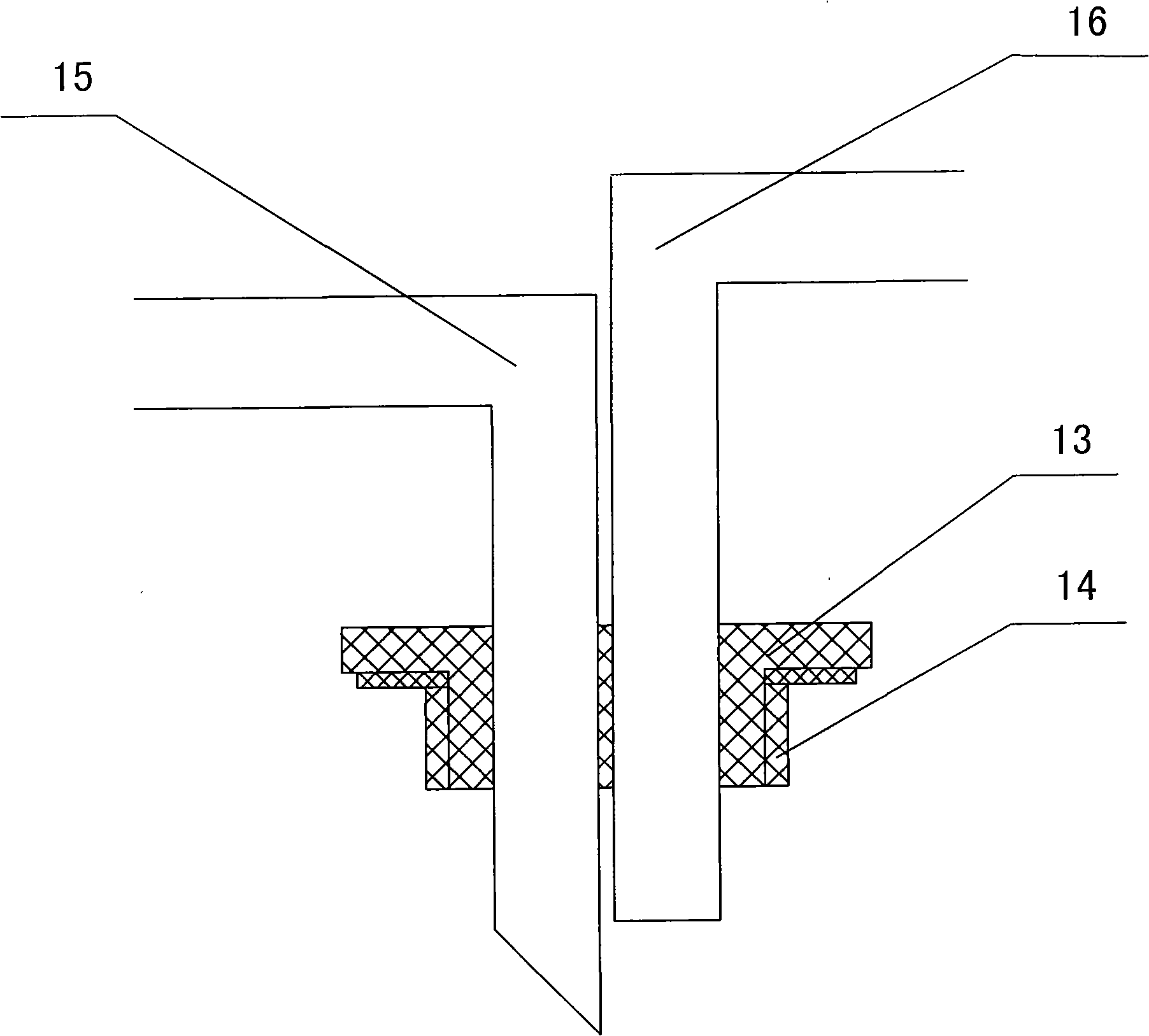

Method used

Image

Examples

Embodiment 1

[0025] Take D-400BS as an example

[0026] According to the above operation method, place a group of (24) batteries on the circuit, and inject the batteries with a density of (1.100±0.005) g / cm 3 (30°C) electrolyte, soak for 2 hours for battery formation, the density of sulfuric acid during the formation process is (1.050±0.005) g / cm 3 (15°C), 6 hours before the end of the formation, switch the high-level acid storage tank, adjust the density of the electrolyte, the sulfuric acid density in the high-level high-density acid tank is (1.280±0.005) g / cm 3 (30°C). The cycle acid change time is 6 hours. The liquid level height is 20mm, and the total forming time is 46 hours.

[0027] When the electrolyte in the battery flows into the low-level acid storage tank and the density of the electrolyte is low, turn on the function of adding concentrated acid and adjust the density to 1.280±0.005g / cm 3 (30°C).

[0028] The battery performance test was carried out on the above-mentioned...

Embodiment 2

[0032] Take D-700 as an example

[0033] According to the above operation method, place a group of (24) batteries on the circuit, and inject the batteries with a density of (1.100±0.005) g / cm 3 (30°C) electrolyte, soak for 2 hours for battery formation, the density of sulfuric acid during the formation process is (1.050±0.005) g / cm 3 (15°C), 8 hours before the end of the formation, switch the high-level acid storage tank, adjust the density of the electrolyte, the sulfuric acid density in the high-level high-density acid tank is (1.290±0.005) g / cm 3 (30°C). The circulating acid change time is 8 hours, and the liquid level is 22mm.

[0034] When the electrolyte in the battery flows into the low-level acid storage tank and the density of the electrolyte is low, the automatic density adjustment system will start the function of adding concentrated acid to adjust the density to 1.290±0.005g / cm 3(30°C). The total integration time is 48 hours.

[0035] The battery performance t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com