Anesthesia apparatus and calibration method of suction valve thereof

A calibration method and inspiratory valve technology, applied in the field of anesthesia machines, can solve the problems of large airway pressure monitoring error, difficult calibration of low flow rate, flow sensor deviation, etc., to eliminate circuit resistance, simplify maintenance work, and not easily damaged deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

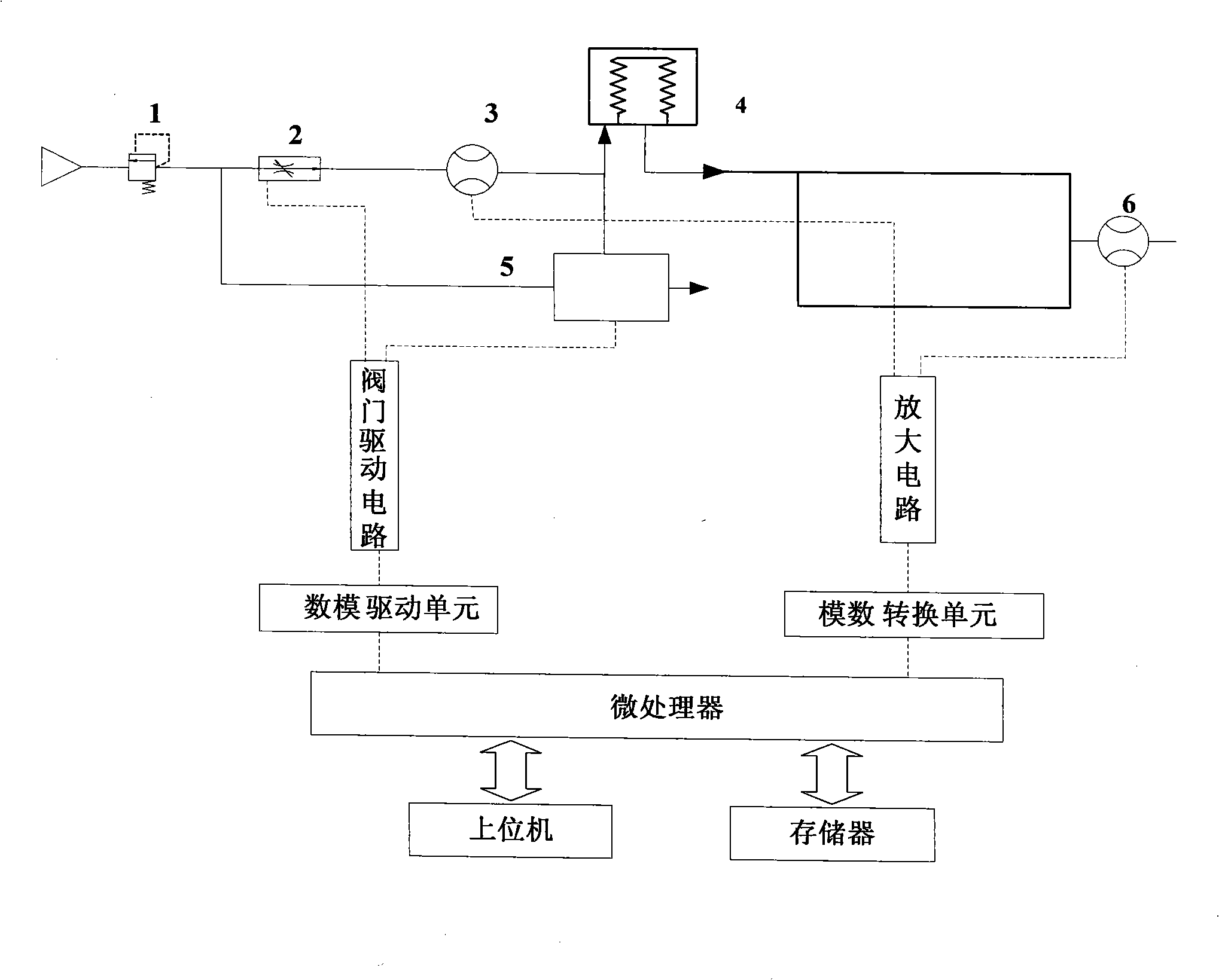

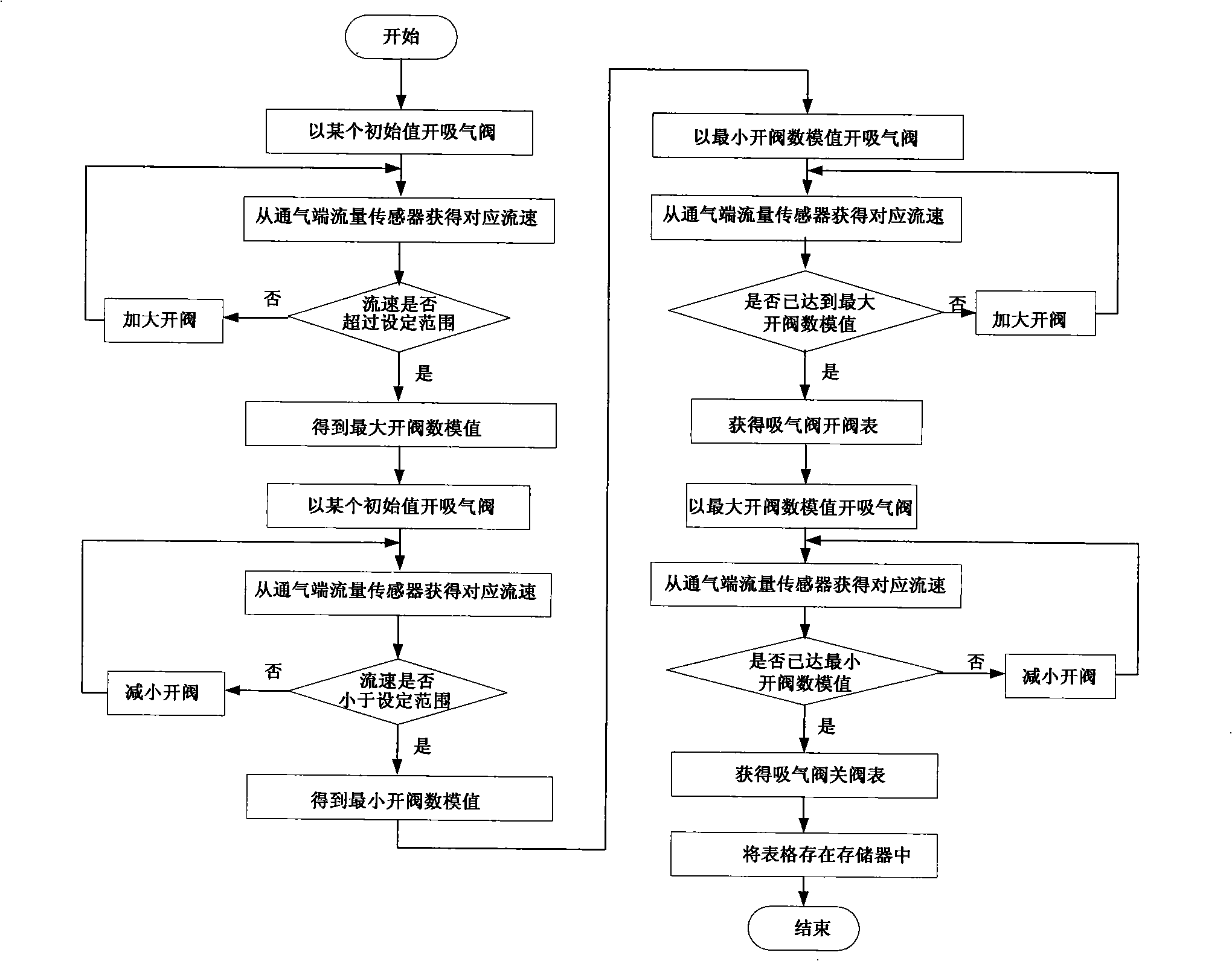

[0025] The specific embodiment of the present invention mainly realizes the automatic calibration of the inspiratory valve by installing a stable and reliable inspiratory valve flow detection device on the driving gas control pipeline inside the breathing air circuit of the original anesthesia machine as the flow rate measurement reference, so as to improve the inspiratory valve. Air valve accuracy. The suction valve flow detection device in this embodiment is the suction valve flow sensor 3 , specifically a fixed-aperture differential pressure flow sensor.

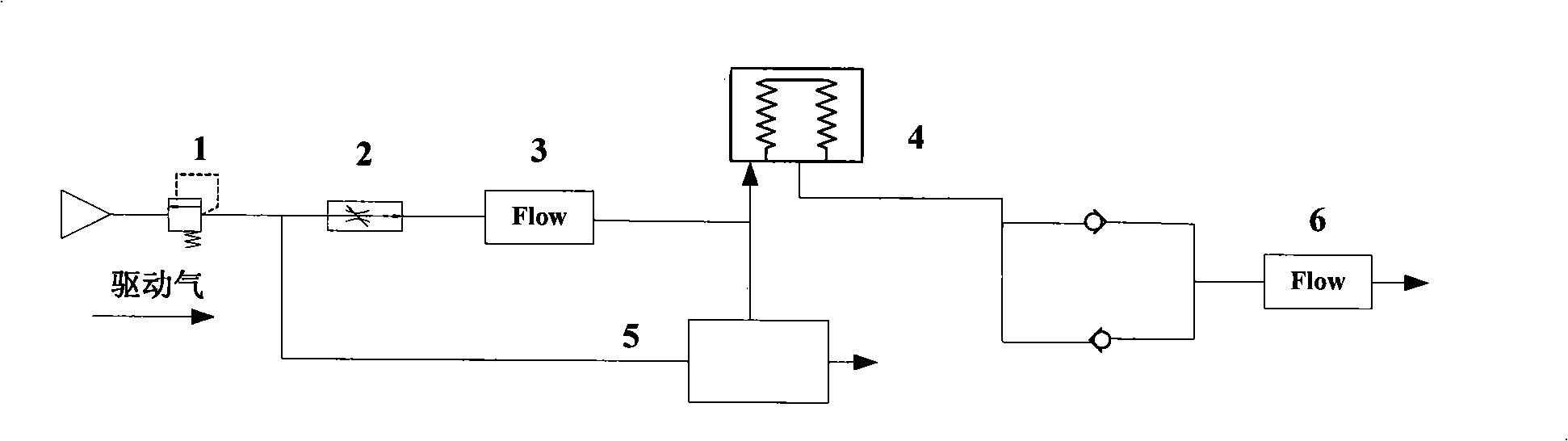

[0026] figure 1 It is a schematic diagram of the air circuit system of the inspiratory valve calibration device of an anesthesia machine according to the specific embodiment of the present invention. The driving air flow passes through the pressure reducing valve 1 and then enters the suction valve 2. During normal work, the gas flowing out of the suction valve 2 will flow into the shell of the bellows 4, and the foldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com