Automatic transmission fluid composition using synthetic oil as base oil

A technology of automatic transmission fluid and composition, which is applied in the direction of lubricating composition, petroleum industry, additives, etc., and can solve problems such as insufficient anti-wear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

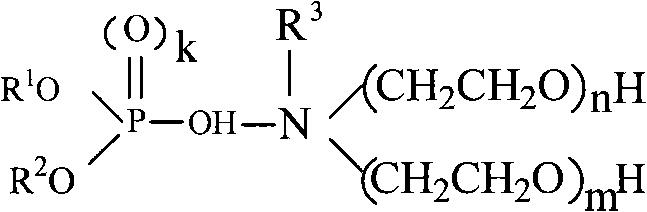

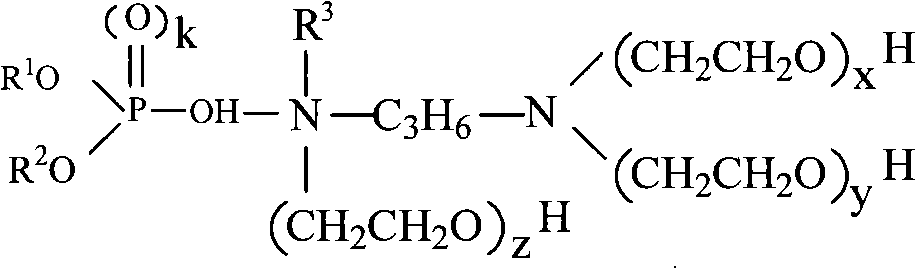

Method used

Image

Examples

preparation example Construction

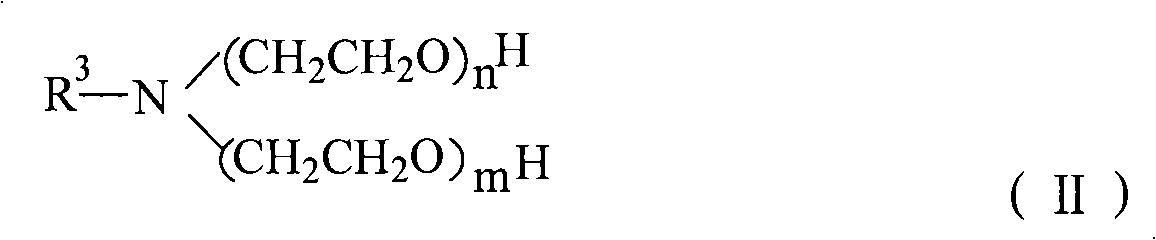

[0047] The preparation method of phosphate amine salt A in the example is: get 195g di-n-butyl phosphite (trade name is T304), add 150g ethoxylated tallow amine (Ethomeen T-12, Akzo Nobel chemical company produces), at 80 Stirring at ±5° C. for 2 h to obtain the phosphate ester amine salt.

[0048] The preparation method of phosphate amine salt B in the example is: get 350g di-n-butyl phosphite, add 425g ethoxylated coconut oil alkylamine (Ethomeen C-15, produced by Akzo Nobel chemical company), at 80 ± 5 ℃ Stir at high temperature for 2 h to obtain the phosphate ester amine salt.

[0049] The preparation method of phosphorous boronated succinimide in the example is: add 195g monopolyisobutenyl succinimide T151, 21.5g di-n-butyl phosphite, 7.8g boric acid, 11g ethoxylated tallow amine (Ethomeen T-12), 1g n-butanol, 2.2g water, blow nitrogen, stir at 95±5°C for 3 hours, gradually raise the temperature to 110°C, remove water and n-butanol under 40mmHg pressure, and obtain phosp...

example 1

[0051] An automatic transmission fluid composition, based on the total weight of the composition, comprising the following components:

[0052] Component (a) phosphate ester amine salt A 0.6%

[0053] Component (b) Monopolyisobutenyl succinimide T151 2%

[0054] Phosphorus boro-succinimide 4%

[0055] Component (c) 2,6-di-tert-butyl-p-cresol T501 0.3%

[0056] Alkyl diphenylamine T534 0.5%

[0057] Base number synthetic calcium sulfonate T105 in component (d) 0.7%

[0058] Component (x) GTL synthetic oil (100°C kinematic viscosity 6.0mm 2 / s) margin

example 2

[0060] An automatic transmission fluid composition, based on the total weight of the composition, comprising the following components:

[0061] Component (a) phosphate ester amine salt A 0.6%

[0062] Component (b) bis-polyisobutenyl succinimide T152 2%

[0063] Boronated succinimide (grade T152B) 4%

[0064] Component (c) 2,6-di-tert-butyl mixed phenol T502 0.2%

[0065] Alkyl diphenylamine T534 0.2%

[0066] Base number sulfurized calcium alkylphenate LZL115A in component (d) 0.2%

[0067] Component (e) polymethacrylate T602D 3%

[0068] Component (i) dodecenylsuccinic acid T746 0.1%

[0069] Component (x) GTL synthetic oil (100°C kinematic viscosity 4.0mm 2 / s) margin

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com