Steel for stamping die and method of manufacture

A manufacturing method and stamping die technology, applied in the direction of manufacturing tools, temperature control, heat treatment process control, etc., can solve the main performance indicators such as yield strength, plastic elongation, section shrinkage, carbide non-uniformity, high production cost, Increase billet energy consumption and product manufacturing costs to achieve the effect of saving energy consumption, reducing billet cost, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1. The chemical composition weight percentage of steel is: C0.38wt%, Mn0.45wt%, Cr5.20wt%, Si0.48wt%, Mo3.71wt%, V0.60wt%, Cu0.21wt%, Ni0.18wt%, P0.011wt%, S0.008wt%, the rest are Fe and unavoidable impurities;

[0041] 2. Process the steel with the above-mentioned chemical composition ratio as follows:

[0042] (1) Casting into 2350Kg steel ingots after electric furnace and refining outside the furnace;

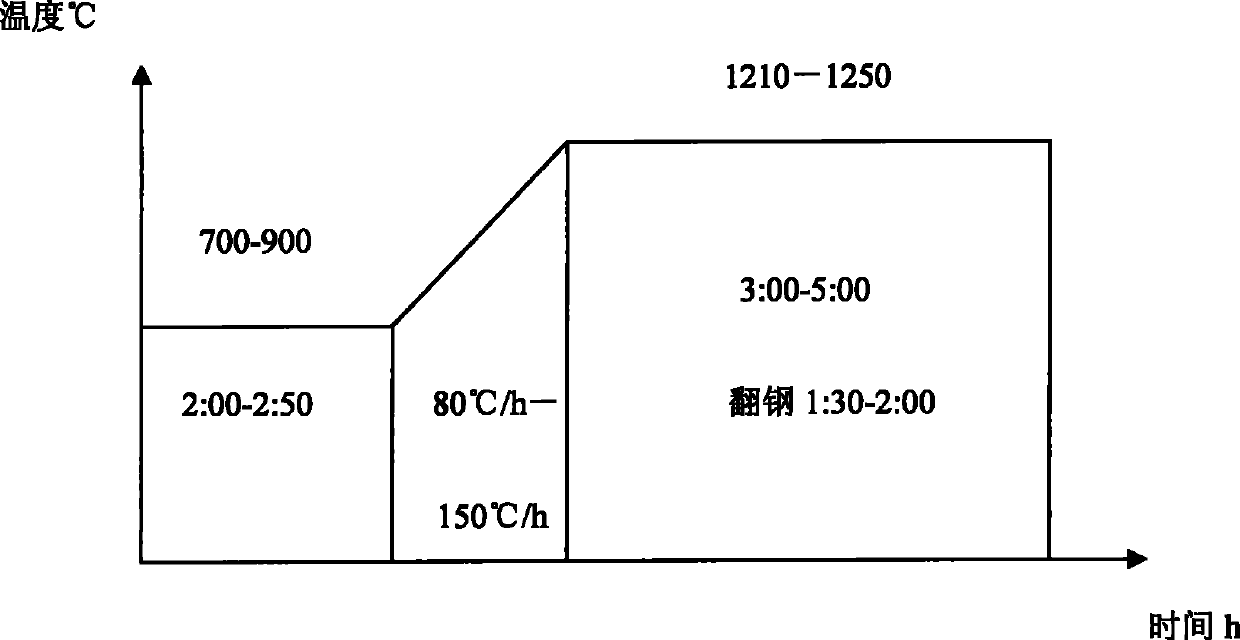

[0043] (2) The steel ingot is heated in the heating furnace of the blooming mill. The furnace temperature of the steel ingot is 780°C. The steel ingot is heated to 1230°C at a heating rate of 100°C / h in the blooming heating furnace and then kept for 4.5 hours. During the heat preservation process, a steel turning treatment is carried out 1.9 hours after the heat preservation starts. The heating process curve is shown in figure 1 shown;

[0044] (3) The steel ingot is first rolled and opened by the blooming mill, the rolling temperature is 1140°C, and the final roll...

Embodiment 2

[0048] 1. The chemical composition weight percentage of steel is: C0.35wt%, Mn0.44wt%, Cr4.70wt%, Si0.50wt%, Mo3.00wt%, V0.55wt%, Cu0.22wt%, Ni0.30wt%, P0.009wt%, S0.007wt%, the rest are Fe and unavoidable impurities;

[0049] 2. Process the steel with the above-mentioned chemical composition ratio as follows:

[0050] (1) Casting into 2350Kg steel ingots after electric furnace and refining outside the furnace;

[0051] (2) The steel ingot is heated in the heating furnace of the blooming mill. The furnace temperature of the steel ingot is 700°C. The steel ingot is heated to 1250°C at a heating rate of 100°C / h in the blooming heating furnace and then kept for 3 hours. During the heat preservation process, a steel turning treatment is carried out 1.7 hours after the heat preservation starts

[0052] (3) The steel ingot is first rolled and opened by the blooming mill, the rolling temperature is 1150°C, and the final rolling temperature is 1020°C;

[0053] (4) After the initial...

Embodiment 3

[0056] 1. The chemical composition weight percentage of steel is: C0.40wt%, Mn0.60wt%, Cr5.23wt%, Si0.30wt%, Mo4.00wt%, V0.40wt%, Cu0.30wt%, Ni0.21wt%, P0.011wt%, S0.015wt%, the rest are Fe and unavoidable impurities;

[0057] 2. Process the steel with the above-mentioned chemical composition ratio as follows:

[0058] (1) Casting into 2350Kg steel ingots after electric furnace and refining outside the furnace;

[0059] (2) The steel ingot is heated in the heating furnace of the blooming mill. The furnace temperature of the steel ingot is 800°C. The steel ingot is heated to 1210°C at a heating rate of 80°C / h in the blooming heating furnace and then kept for 5 hours. During the heat preservation process, a steel turning treatment is carried out 1.5 hours after the heat preservation starts

[0060] (3) The steel ingot is first rolled and opened by the blooming mill, the rolling temperature is 1120°C, and the final rolling temperature is 1070°C;

[0061] (4) After the initial ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com