Gliding resistant foundation structure

A basic structure, anti-slip technology, applied in the field of building infrastructure, can solve problems such as increased self-weight, concrete waste, fracture, etc., to increase the anti-slip capability, economical and reasonable design, and increase reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

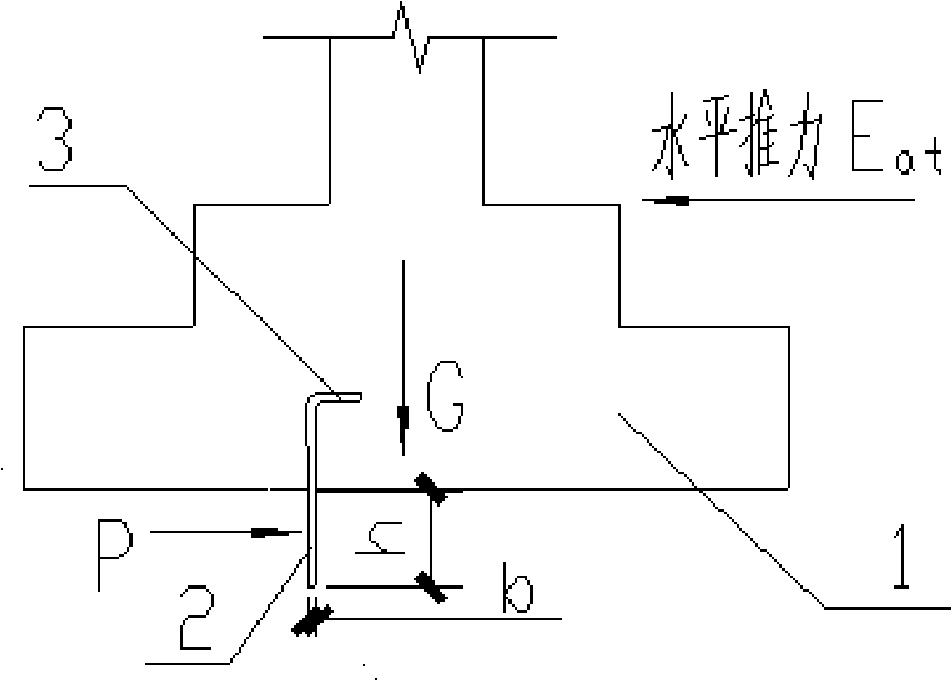

[0023] Embodiment 1, as shown in FIG. 1 , the anti-skid toe 2 is made of steel plate, its upper part goes deep into the foundation base 1 , and its lower part goes deep into the foundation of the foundation. In order to increase the anti-slip capability, there is a bending section 3 at the top of the sliding toe 2 . The steel plate thickness b and height h of the anti-skid toe of the steel plate are determined through design calculations, and their values should be able to meet the shear and bending resistance at the interface between the resistance and the base. After meeting the design requirements, the height h of the anti-skid toe 2 deep into the foundation is 250-450 mm, the height of the upper part deep into the foundation base 1 is the same as the height of the bottom deep into the foundation, and the value of the steel plate thickness b The range should satisfy 0.02h~0.03h, and its length should be set along the general length of the foundation.

Embodiment 2

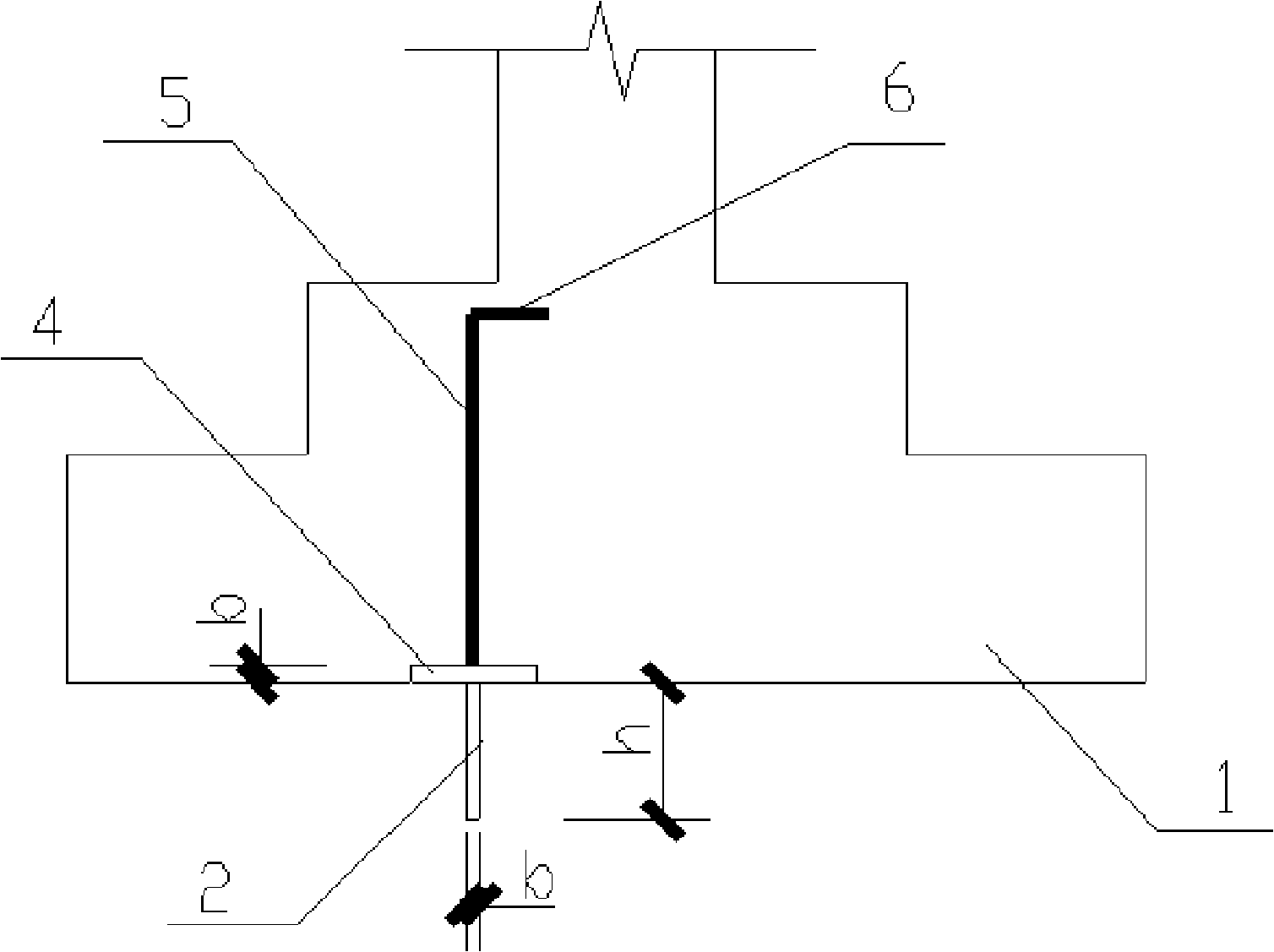

[0024] Embodiment two, as shown in Figure 3, steel plate 4 is set on the top of anti-skid toe 2, adopts " T font fillet weld to connect, and on steel plate 4 welding anchor pulls steel bar 5, anti-skid toe 2, steel plate 4, Anchor the steel bar 5 to form a member, place it in the excavated foundation pit, and then pour the foundation concrete. In order to ensure that the position of the anti-slip toe does not shift during construction, the The anchor bar can be spot-welded with the base plate steel bar for positioning. The steel plate 4 width value is 100mm, and its length value is slightly smaller than the foundation ground width value. In order to increase the anti-sliding ability, there is a bending section at the top of the anchor bar 5 6. The steel plate thickness b and height h of the anti-skid toe of the steel plate are determined through design calculations, and its requirements are the same as those in Embodiment 1. The diameter d of the anchoring steel bar is 8-10mm, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com