Method for removing obstruction of atomizer

A technology of atomizer and blockage, applied in the direction of injection device, etc., can solve the problems of easily damaged inner pipe, blockage of concentric atomizer, scrapping, etc., and achieve the effect of high safety and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

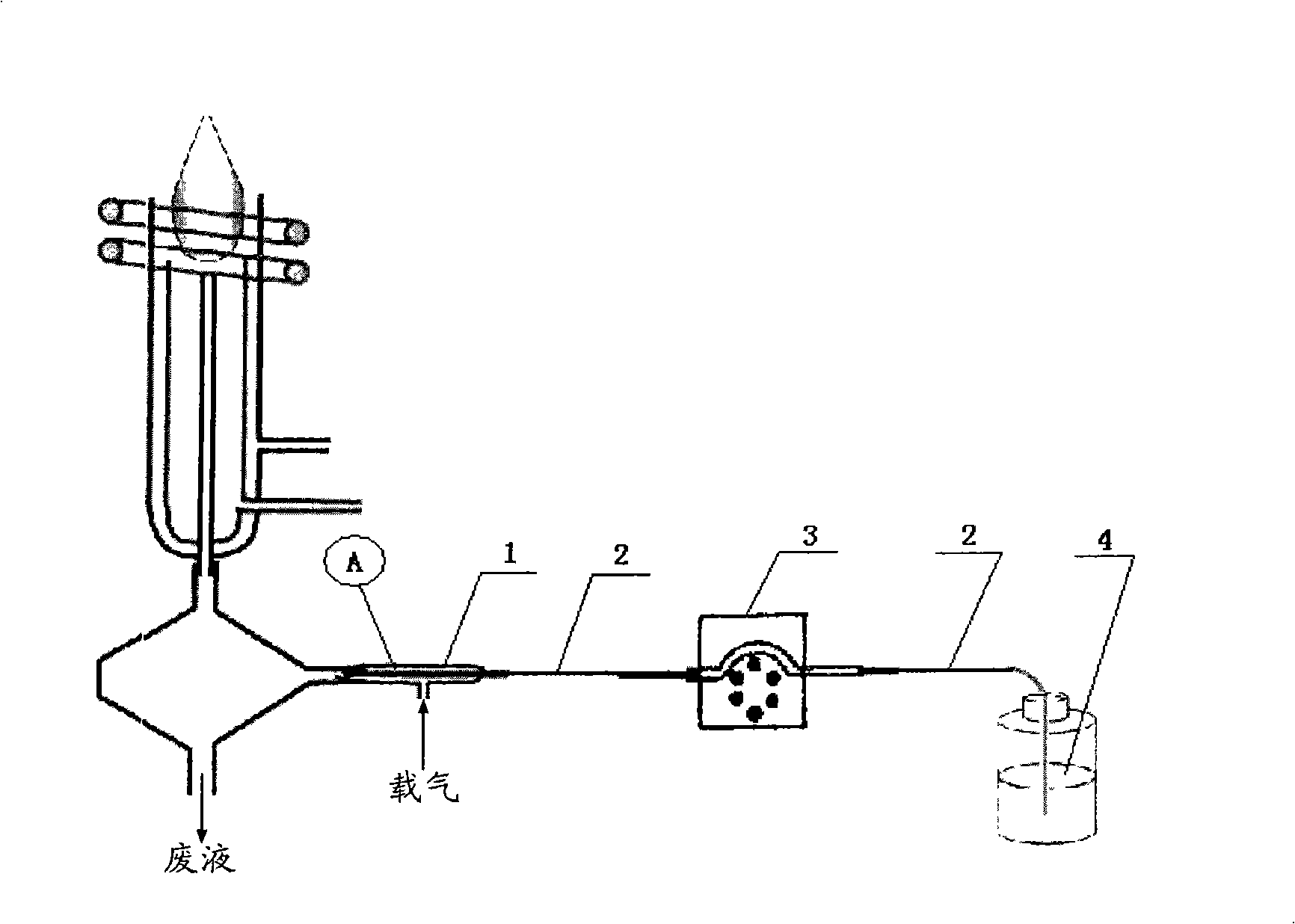

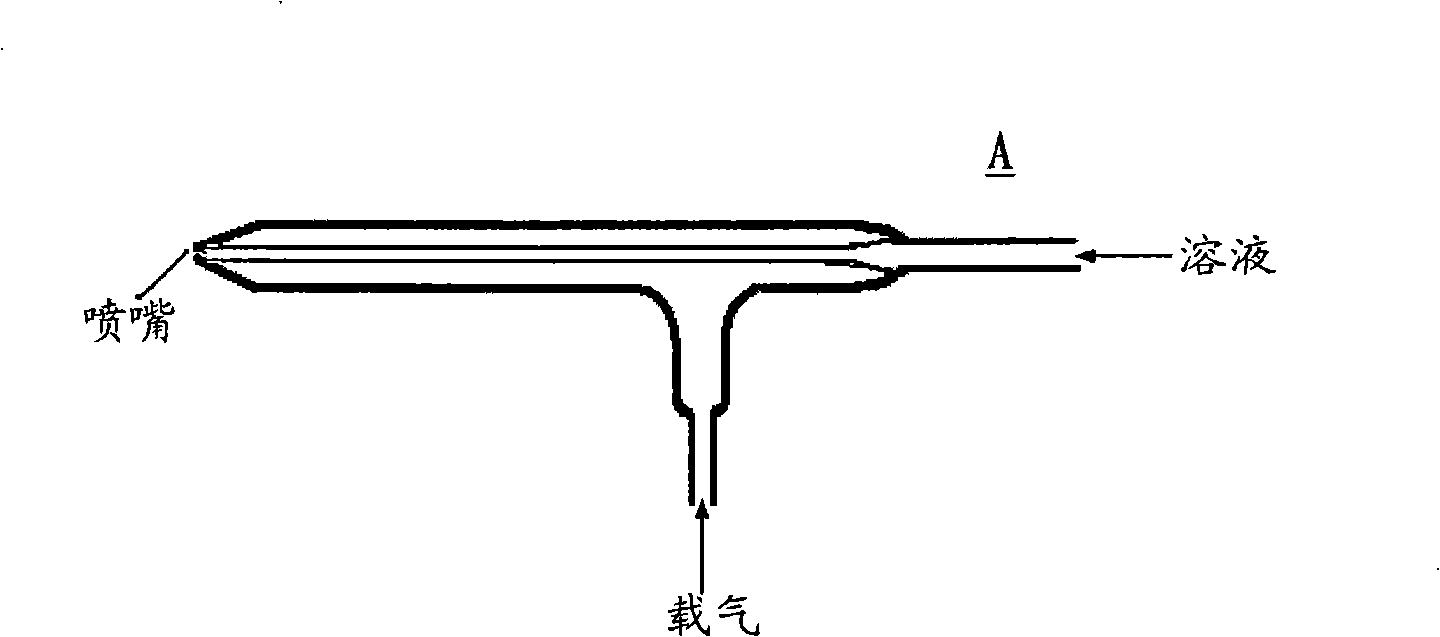

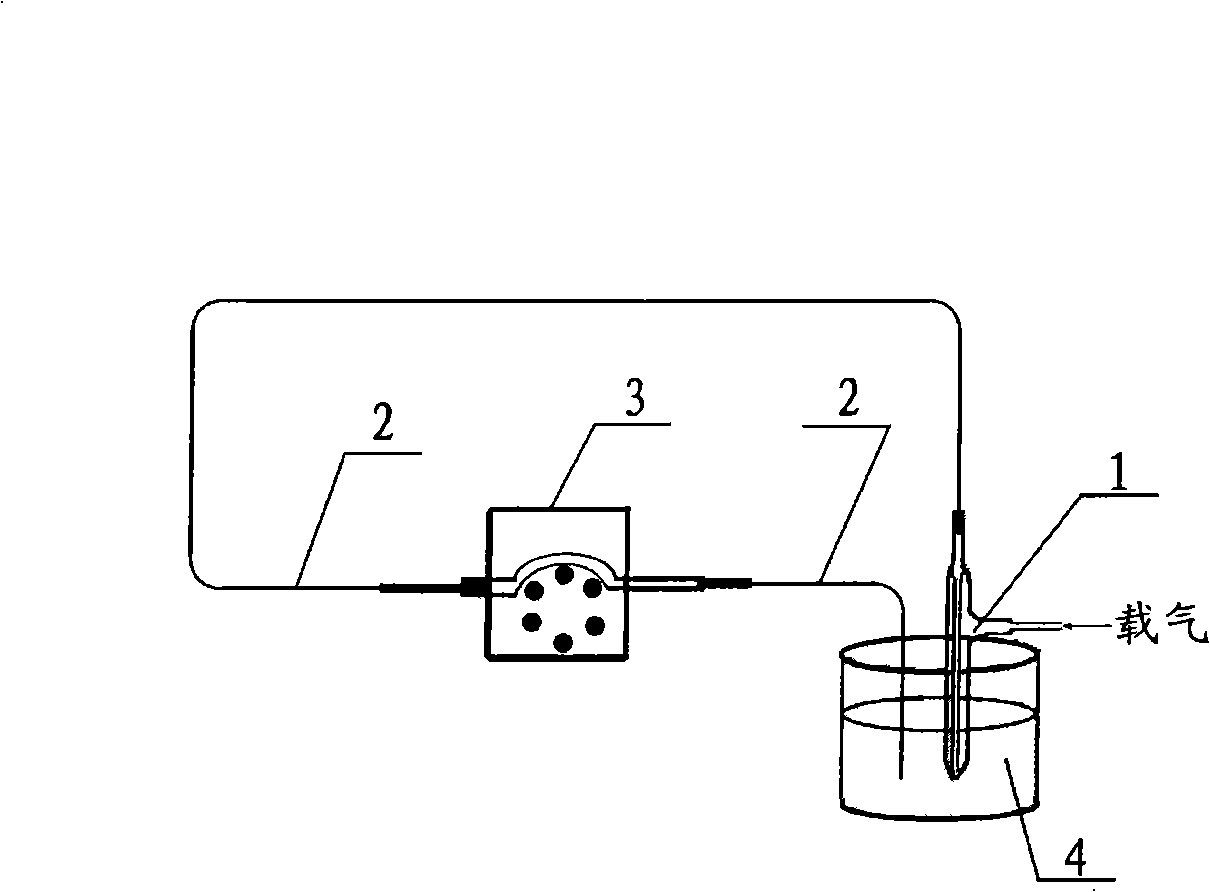

[0023] Embodiment 1, with reference to figure 1 , figure 2 and image 3 .

[0024] The first technical solution of the present invention is a method for removing blockages in an atomizer by using a cleaning solution. The technical solution is to replace the original sample solution with the cleaning solution 4 by using the atomization airflow pipeline, the sampling capillary inner tube 2 and the peristaltic pump 3 on the original equipment under the original normal working connection state. A method of clearing a blockage. During operation, the following working methods are adopted:

[0025] First pull out the atomizer 1 from the atomization chamber, put the nozzle end of the atomizer into the container containing the cleaning solution 4; the cleaning solution 4 is 25mL concentrated hydrochloric acid (HCl) and 15mL concentrated nitric acid (HNO 3 ) mixed solution, then add 80mL distilled water and mix well. Use the peristaltic pump 3 to drive the cleaning solution 4 int...

Embodiment 2

[0027] On the basis of embodiment 1, the cleaning solution that embodiment 2 adopts selects 30mL concentrated hydrochloric acid (HCl) and 10mL concentrated nitric acid (HNO 3 ), then add 90mL of distilled water and mix evenly, and heat the mixed solution to 50°C; the rotation speed of the peristaltic pump 3 is 120 rpm, and the pressure of the atomizing airflow is 25psi.

Embodiment 3

[0029] On the basis of embodiment 1, the cleaning solution that embodiment 3 adopts selects 40mL concentrated hydrochloric acid (HCl) and 20mL concentrated nitric acid (HNO 3 ), then add 100mL of distilled water and mix evenly; the rotation speed of the peristaltic pump 3 is 160 rpm, and the pressure of the atomizing airflow is 40psi.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com