Antifoulant additive and preparation method thereof

An additive and anti-fouling technology, applied in anti-fouling/underwater coatings, biocide-containing paints, coatings, etc., can solve problems such as difficulties, discontinuities, and complicated processes, and achieve good anti-fouling effects, increased inhibition rates, The effect of improving the antifouling ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

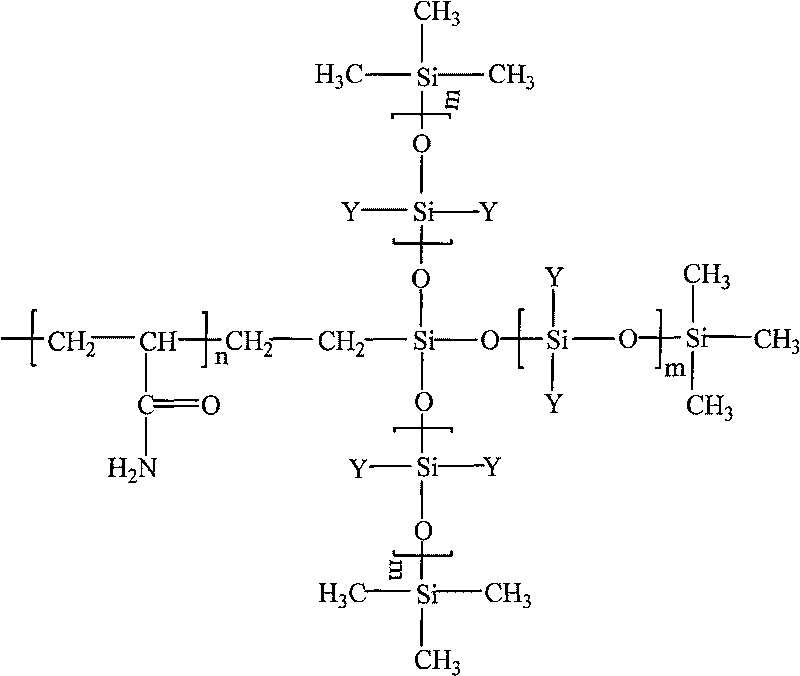

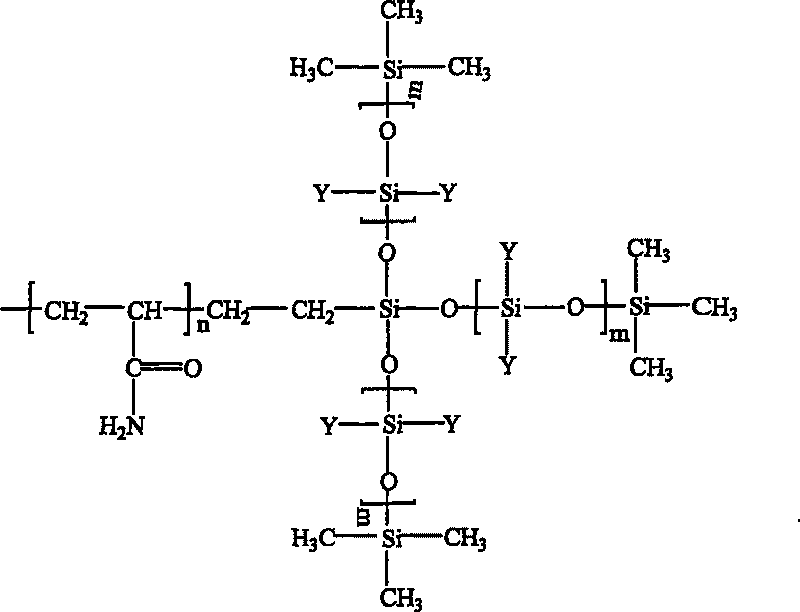

Image

Examples

Embodiment 1

[0017] Embodiment 1: the preparation of antifouling additive

[0018] Add 10g of acrylamide, 0.1g of acrylic acid and 100mL of distilled water successively into a 250mL four-necked flask, and pass nitrogen (N 2 ) protection for 30 minutes, add 0.05g potassium persulfate (K 2 S 2 o 8 ), continue to pass nitrogen (N 2 ) for 10 minutes, when the temperature rises to 50°C, stop heating, start timing after the temperature rises to 70°C, react for 30 minutes, add 0.03g potassium persulfate (K 2 S 2 o 8 ) continue to pass nitrogen (N 2 ) for 30 minutes;

[0019] Then the temperature was raised to 90° C., 0.25 g of potassium hydroxide (KOH) was added, and nitrogen gas (N 2 ) 10 minutes later, start timing and add dropwise 1g coupling agent vinyltriethoxysilane (AH-151), 2g octamethyltetrasiloxane (D4), 0.1g hexamethyldisiloxane (MM ) and 0.4g dimethyl sulfoxide (DMSO), dropwise in 30 minutes, stop heating after 3 hours of reaction, after cooling to room temperature, discharge...

Embodiment 2

[0021] Embodiment 2: the preparation of antifouling additive

[0022] Add 10g of acrylamide, 0.1g of acrylic acid and 100mL of distilled water successively into a 250mL four-necked flask, and pass nitrogen (N 2 ) to protect for 30 minutes, after adding 0.05g azobisisobutyronitrile, continue nitrogen gas (N 2 ) for 10 minutes, when the temperature rises to 50°C, stop heating, start timing after the temperature rises to 70°C, react for 30 minutes, add 0.03g azobisisobutyronitrile and continue to flow nitrogen (N 2 ) for 30 minutes;

[0023] Then the temperature was raised to 90° C., 0.25 g of potassium hydroxide (KOH) was added, and nitrogen gas (N 2 ) 10 minutes later, start timing and add dropwise 1g coupling agent vinyltriethoxysilane (AH-151), 2g octamethyltetrasiloxane (D4), 0.1g hexamethyldisiloxane (MM ) and 0.4g dimethyl sulfoxide (DMSO), dropwise in 30 minutes, stop heating after 3 hours of reaction, after cooling to room temperature, discharge to obtain the reactant...

Embodiment 3

[0025] Embodiment 3: the preparation of antifouling additive

[0026] Add 10g of acrylamide, 0.1g of acrylic acid and 100mL of distilled water successively into a 250mL four-necked flask, and pass nitrogen (N 2 ) protection for 30 minutes, after adding 0.05g dibenzoyl peroxide, continue nitrogen (N 2 ) for 10 minutes, when the temperature rises to 50°C, stop heating, and start timing after the temperature rises to 70°C, react for 30 minutes, add 0.03g dibenzoyl peroxide and continue nitrogen flow (N 2 ) for 30 minutes;

[0027] Then the temperature was raised to 90° C., 0.25 g of potassium hydroxide (KOH) was added, and nitrogen gas (N 2 ) 10 minutes later, start timing and add dropwise 1g coupling agent vinyltriethoxysilane (AH-151), 2g octamethyltetrasiloxane (D4), 0.1g hexamethyldisiloxane (MM ) and 0.4g dimethyl sulfoxide (DMSO), dropwise in 30 minutes, stop heating after 3 hours of reaction, after cooling to room temperature, discharge to obtain the reactant;

[0028]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com