Hook line transmission mechanism of sewing machine

A transmission mechanism and sewing machine technology, which is applied to the sewing machine collar mechanism, sewing machine components, sewing equipment, etc., can solve the problems of high cost, inconvenient maintenance, high noise, etc., and achieve the effect of low cost, simple structure and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings.

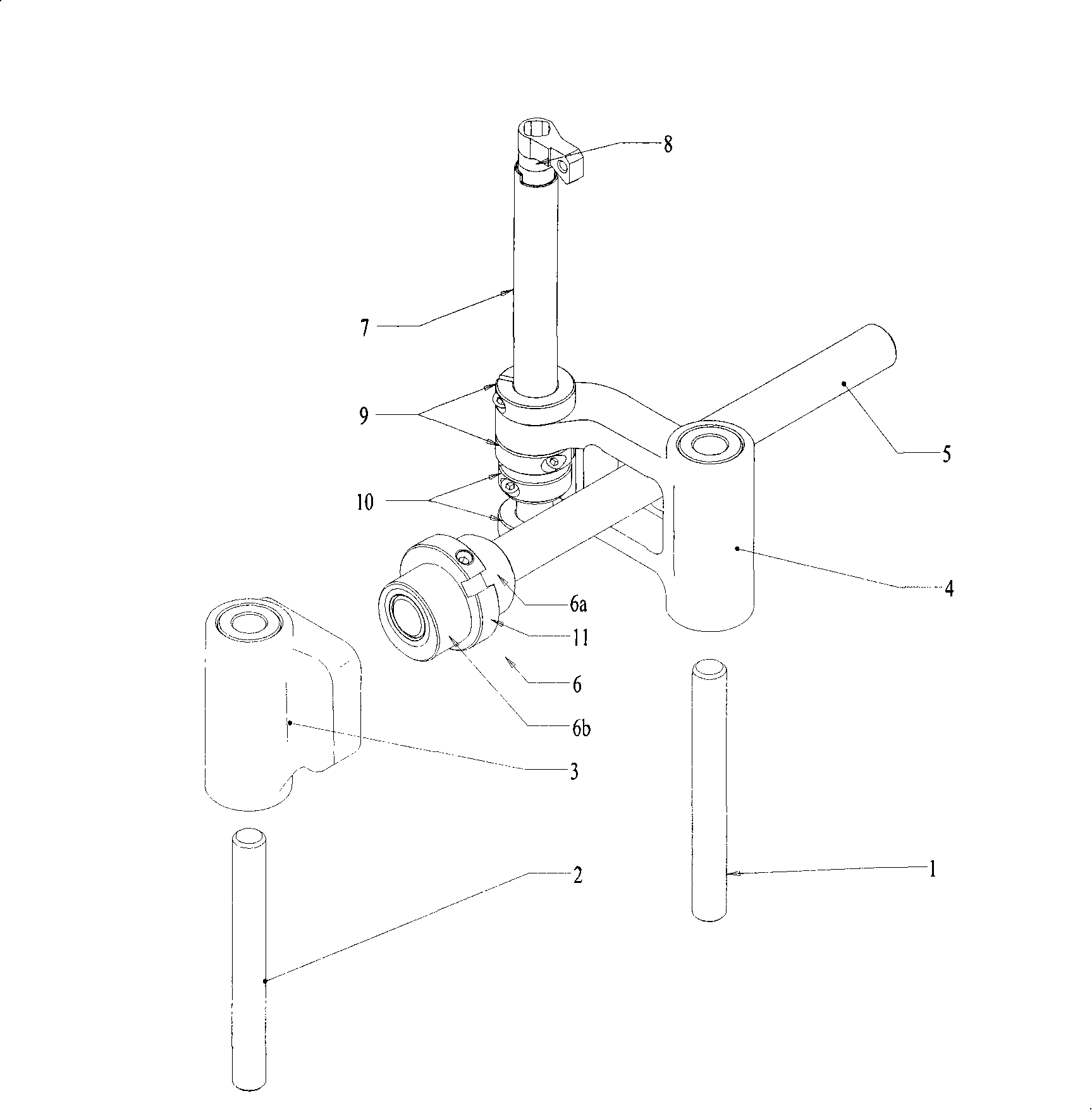

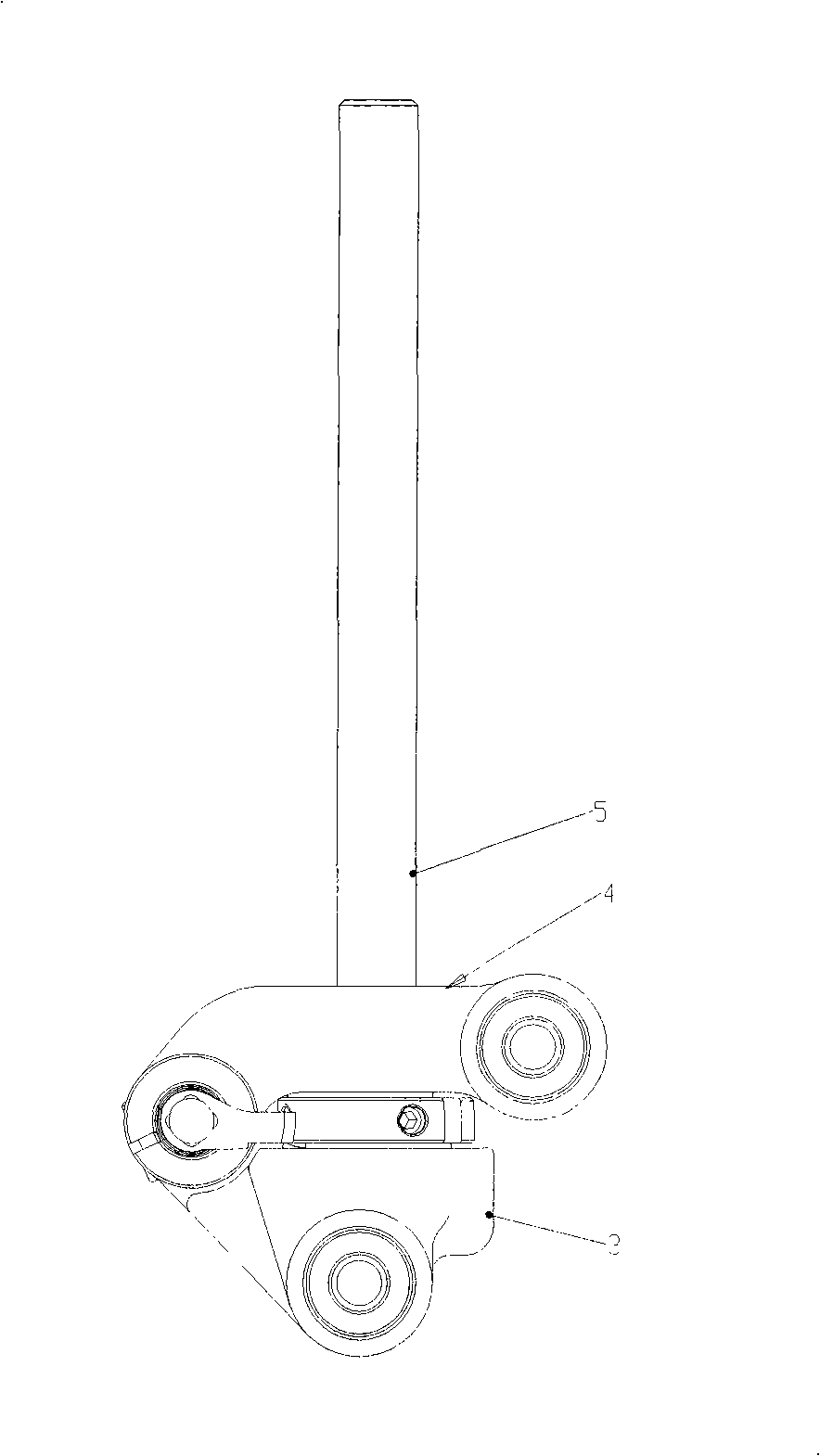

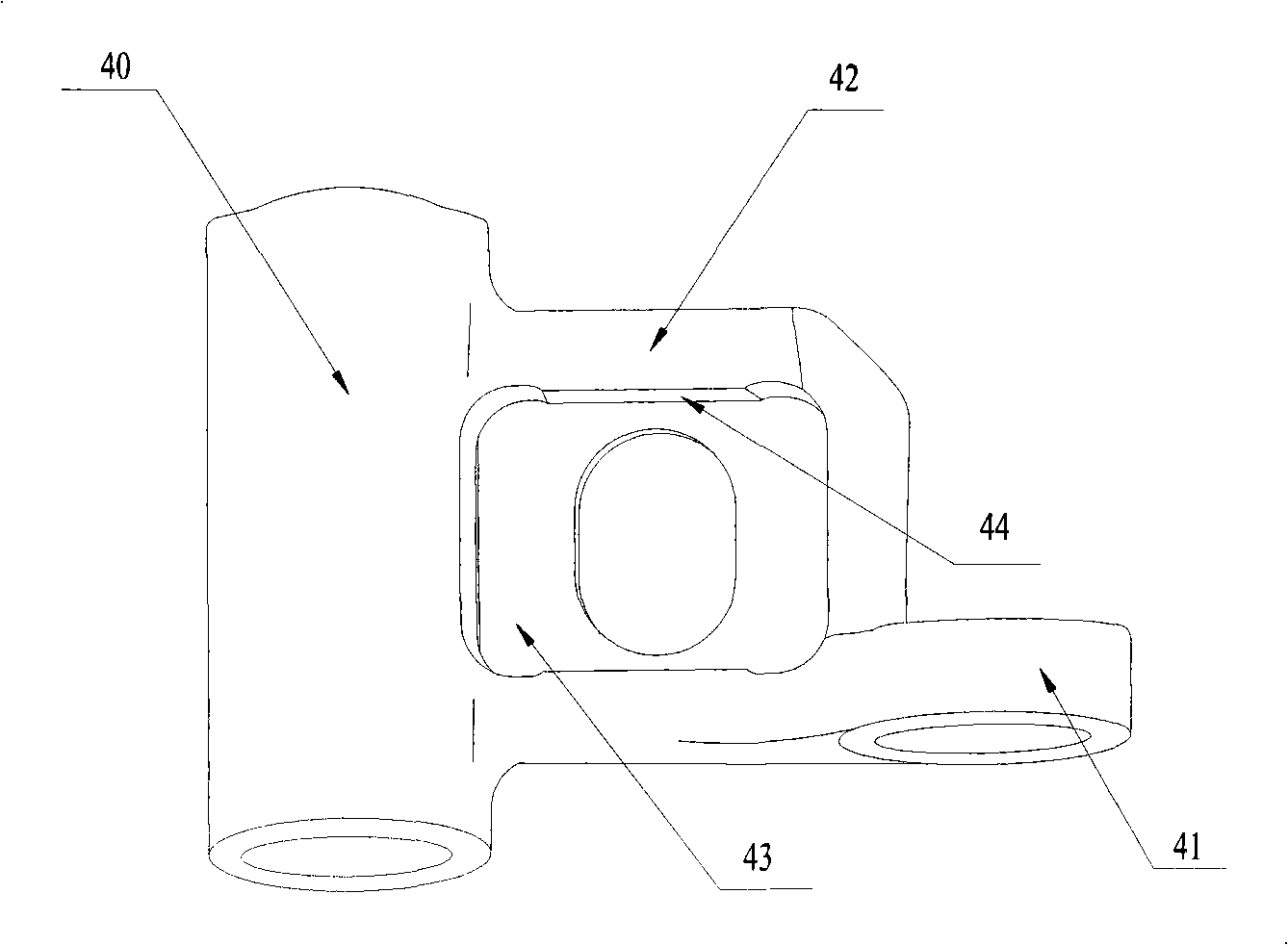

[0012] Such as figure 1 , figure 2 As shown, the present invention comprises a transmission shaft 5, a tubular crochet base driving rod 7, a swing piece driving rod 8, a crochet base driving slide seat 4 and a swinging piece slide seat 3, and the tubular crochet base driving rod 7 is arranged on the vertical side of the transmission shaft 5. In the plane and the two do not intersect; the swing piece drive rod 8 is installed in the crochet seat drive rod 7 and moves up and down along the inner cavity of the crochet seat drive rod 7; one end of the transmission shaft 5 is concentrically sleeved with the first cam 6a and the second The double driving cam 6 composed of two cams 6b, and the cam surfaces of the first cam 6a and the second cam 6b are axially symmetrical, and an isolation retaining ring is arranged between the first cam 6a and the second cam 6b.

[0013] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com