Production method of PE-RT oxygen blocking pipe

A manufacturing method, PE-RT technology, applied to pipes, rigid pipes, pipes/pipe joints/pipe fittings, etc., can solve problems such as uneven distribution of oxygen barrier layer, lack of shading properties of pipe materials, unstable oxygen barrier rate of pipe materials, etc. , to achieve the effects of stable oxygen barrier rate, uniform outer layer thickness, improved production efficiency and appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

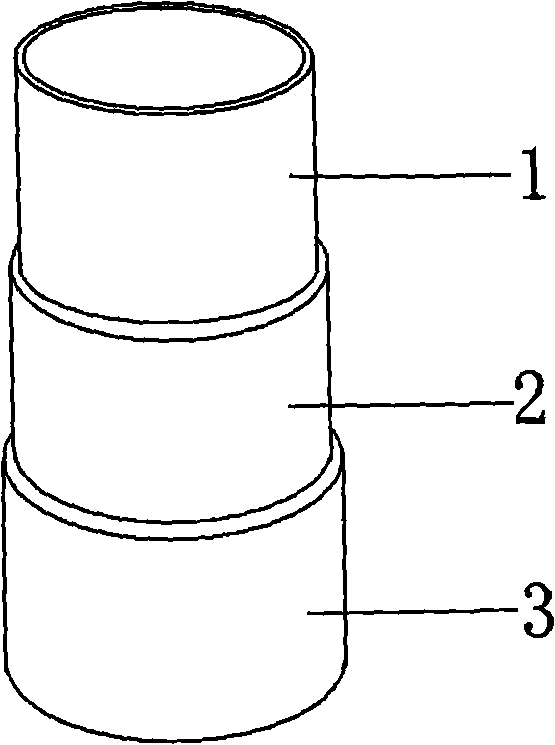

[0021] see figure 1 . Heat Mitsui 528 to 210°C, after melting, add red color masterbatch according to the weight ratio of Mitsui 528 and red color masterbatch is 1.23, and mix evenly. The resulting glue is then coated on the PE-RT layer 1 as the inner layer to form an adhesive layer as the middle layer 2 . Immediately thereafter, an oxygen barrier material EVOH is coated on the adhesive layer 2 to form an oxygen barrier layer 3 as an outer layer. After the glue is cooled and solidified, it is made into a PE-RT oxygen barrier tube.

Embodiment 2

[0023] see figure 1 . Heat Mitsui 528 to 215°C, after melting, add red color masterbatch according to the weight ratio of Mitsui 528 and red color masterbatch is 1.20, and mix evenly. The resulting glue is then coated on the PE-RT layer 1 as the inner layer to form an adhesive layer as the middle layer 2 . Immediately thereafter, an oxygen barrier material EVOH is coated on the adhesive layer 2 to form an oxygen barrier layer 3 as an outer layer. After the glue is cooled and solidified, it is made into a PE-RT oxygen barrier tube.

Embodiment 3

[0025] see figure 1 . Heat Mitsui 528 to 220°C, after melting, add red color masterbatch according to the weight ratio of Mitsui 528 to red color masterbatch is 1.25, and mix well. The resulting glue is then coated on the PE-RT layer 1 as the inner layer to form an adhesive layer as the middle layer 2 . Immediately thereafter, an oxygen barrier material EVOH is coated on the adhesive layer 2 to form an oxygen barrier layer 3 as an outer layer. After the glue is cooled and solidified, it is made into a PE-RT oxygen barrier tube.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com