Safety device

A technology of safety equipment and safety ropes, applied in the directions of seat belts, life-saving equipment, hoisting devices, etc., can solve the problems of not being replaced, dangerous continued use, safety pulleys not showing anti-fall events, etc., to achieve the frequency of inspection and adjustment Low, easy-to-setup effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

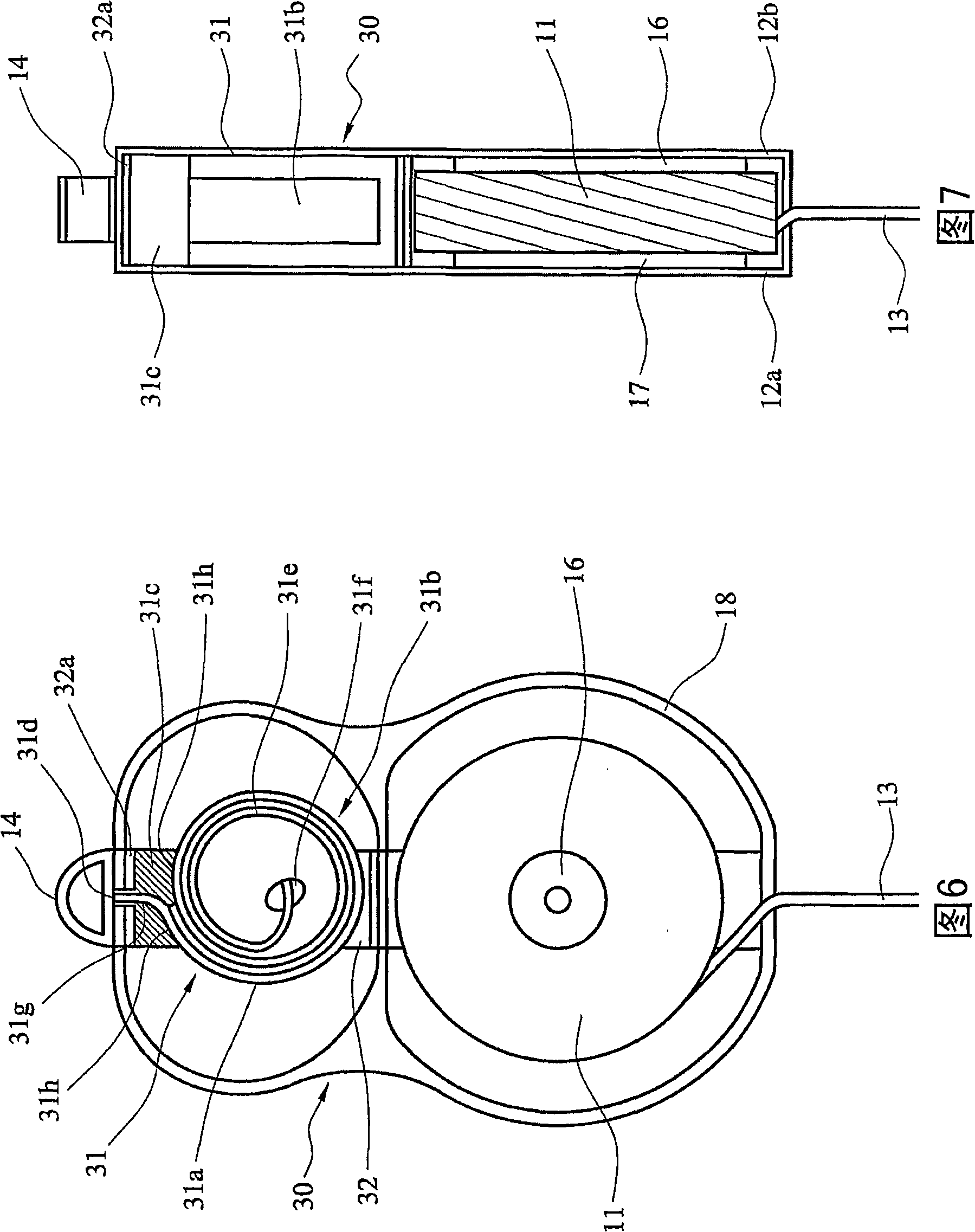

[0059] Similar to the first embodiment, an end stopper 31f is provided as a safety precaution.

[0060] Preferably, the deformation means 31c is formed of plastic.

[0061] The linear energy absorber 31 of the third embodiment has the advantage of being particularly compact and mechanically simple.

[0062] In all embodiments of the present invention, it is generally preferred to use a constant force type linear energy absorber having a substantially constant deployment load required to sustain deployment of the energy absorber throughout its range of deployment. That is, in the illustrated embodiments, the unwinding load required to unroll the stainless steel strip from the coil store through the deforming device is constant along the entire length of the stainless steel strip. Because if such a linear energy absorber is provided, this constant deployed load is the maximum load that can be safely applied to the user during a fall arrest event and maximizes the amount of energy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com