Electric driving hydraulic device, braking system and automobile

A hydraulic device and electric drive technology, which is applied in the direction of brake safety system, brake transmission device, brake, etc., can solve the problem of pressure waste of oil pressure accumulator, and achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

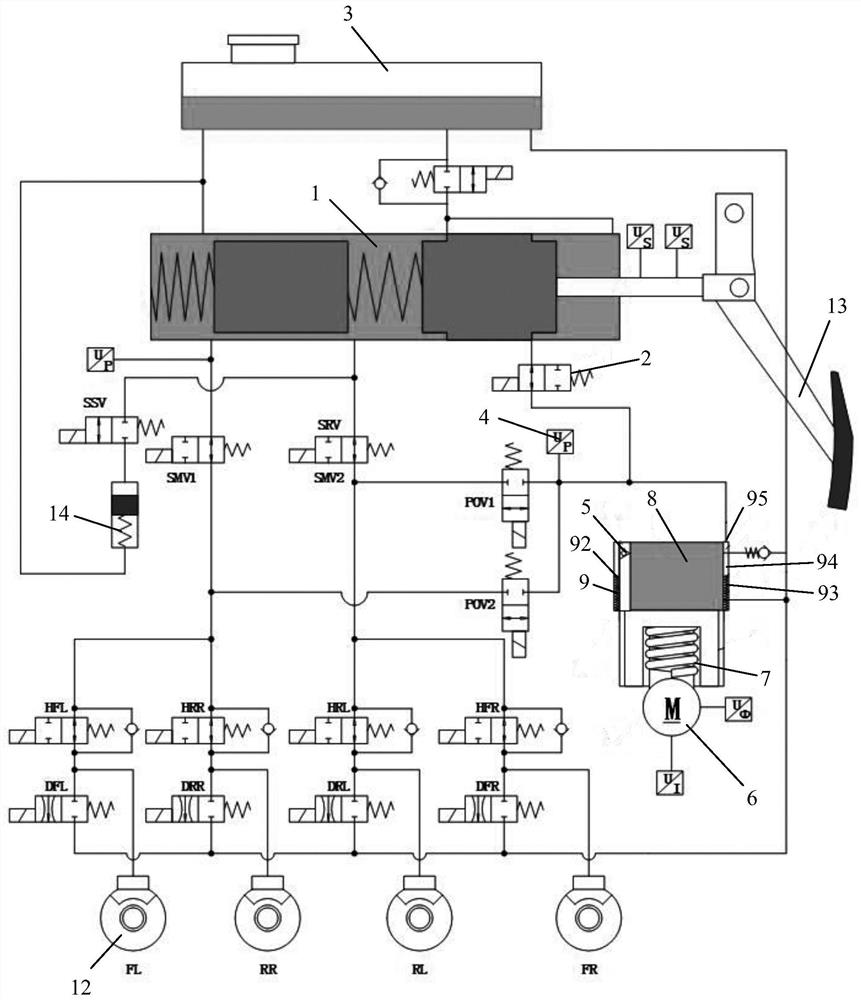

[0049] Such as Figure 1 to Figure 4 As shown, the brake system provided by the first embodiment of the present invention includes a master cylinder 1 , a master cylinder solenoid valve 2 , a liquid storage pot 3 , a controller, a pressure sensor 4 and an electric drive hydraulic device 6 .

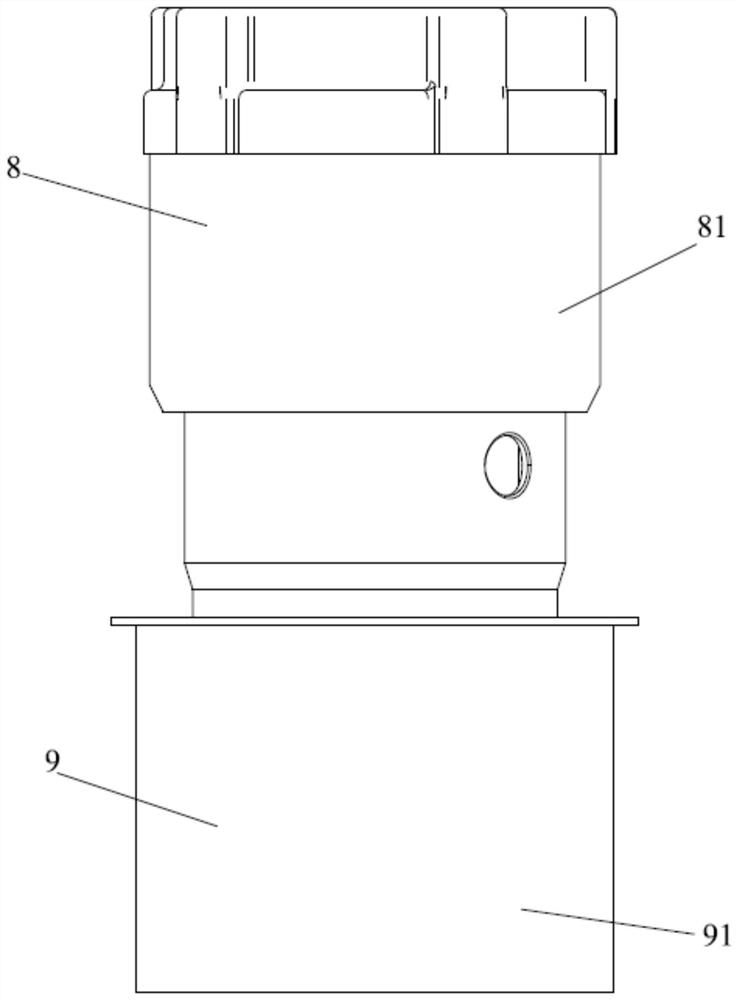

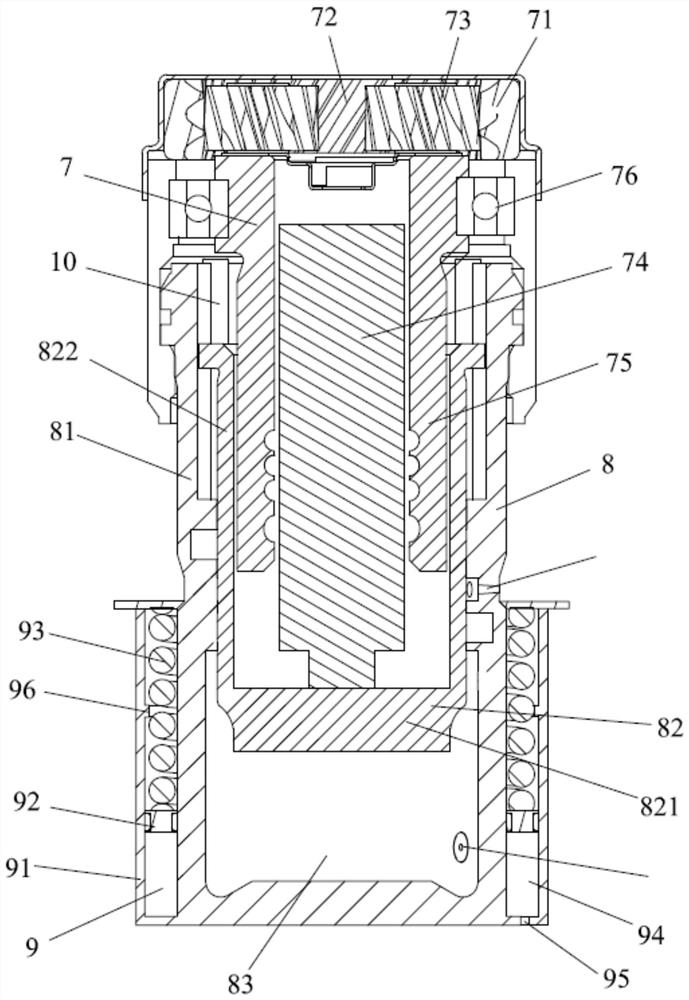

[0050] The electric drive hydraulic device includes a motor 6 , a transmission device 7 , a piston pump 8 and a hydraulic accumulator 9 . The piston pump 8 includes a piston pump housing 81 and a piston pump piston 82. A piston pump chamber 83 is formed in the piston pump housing 81. The hydraulic accumulator 9 includes a hydraulic accumulator housing 91, a hydraulic accumulator Energizer piston 92 and elastic member 93, the hydraulic accumulator housing 91 is fixed or integrally formed on the first end of the piston pump housing 81, the hydraulic accumulator housing 91 and the piston pump A hydraulic accumulator chamber 94 is formed between the first ends of the housing 81 , and a flow ...

no. 2 example

[0079] Figure 5 Shown is a schematic diagram of the braking system provided by the second embodiment of the present invention.

[0080] The difference from the first embodiment is:

[0081] The piston pump housing 81 is provided with a piston pump oil port 85, a piston pump solenoid valve 15 is connected between the piston pump oil port 85 and the master cylinder solenoid valve 2, and the hydraulic accumulator liquid outlet A hydraulic accumulator solenoid valve 16 is connected between 95 and the master cylinder solenoid valve 2 .

[0082] In addition to the pressure sensor 4 of the traditional braking system, another pressure sensor 17 is added, and the added pressure sensor 17 is arranged on a separate pipeline connected to the fluid outlet 95 of the hydraulic accumulator.

[0083] In this way, there are two oil paths in the piston pump chamber 83 , and one oil path is: piston pump chamber 83 - piston pump solenoid valve 15 - second solenoid valve - brake wheel cylinder 1...

no. 3 example

[0086] In addition, the third embodiment of the present invention provides an automobile, which includes the electric drive hydraulic device of the above embodiment or the brake system of the above embodiment.

[0087] Preferably, the car is a fully automatic intelligent driving car (unmanned car). The braking system can perform braking according to the driver's braking request (such as stepping on the brake pedal), or can perform fully automatic braking according to signals collected by external sensors, cameras and other equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com