Glass picture manufacturing process and equipment

A technology of making crafts and glass paintings, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of not being able to use outdoors, low artistic value, easy aging, etc., to achieve vivid and lifelike techniques, practical artistic value, bright color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] (a) Painting on the glass: select colorless transparent glass with a thickness of 4 millimeters; select the painting pigment prepared by the above (2) formula for use, and directly paint on the glass surface to complete the drawing of the overall glass picture:

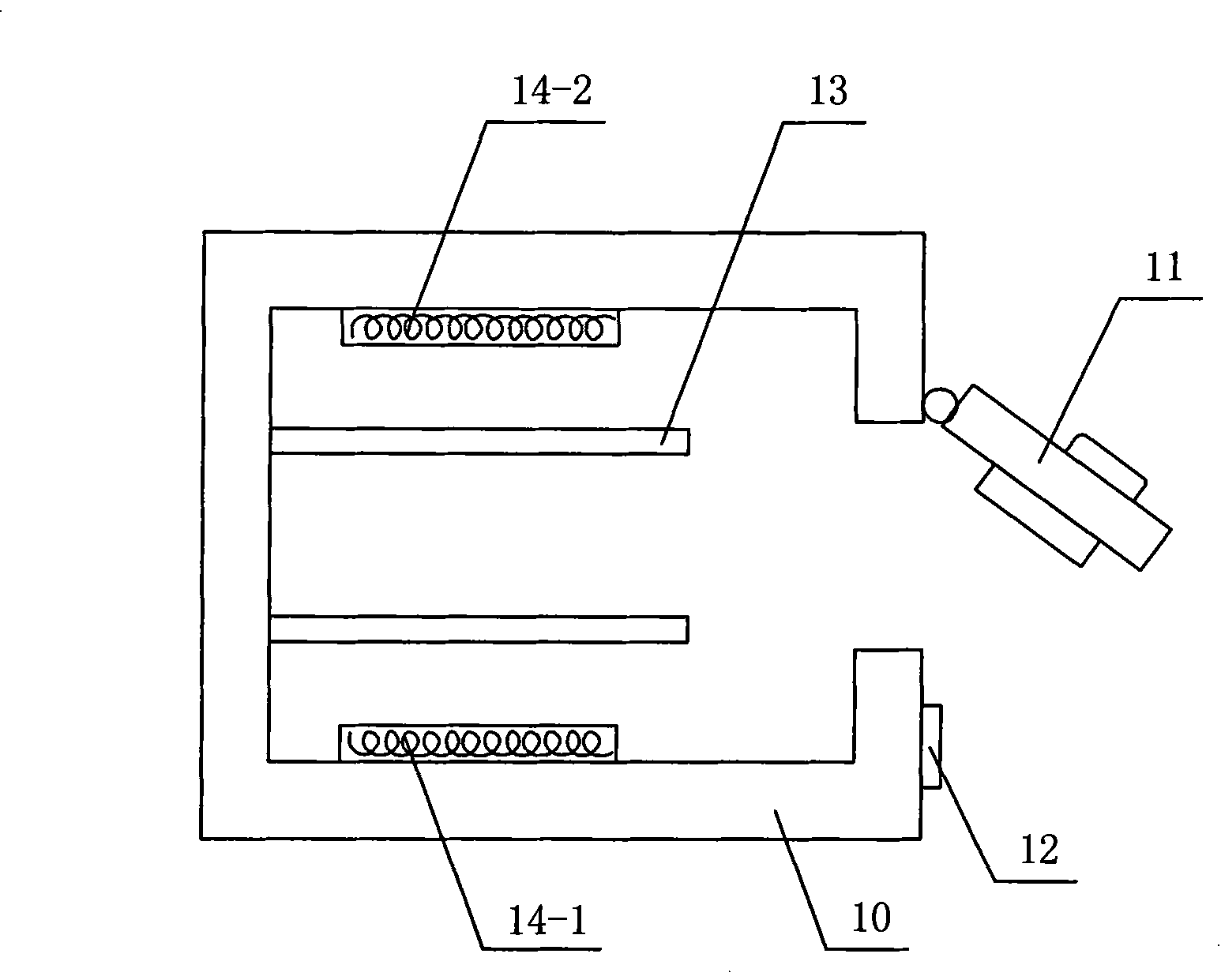

[0055] (b) Low-temperature drying: place the drawn glass painting on figure 1 The shown drying oven is dried on the bracket 13, and the drying temperature is 110°C, and the picture is completely dried;

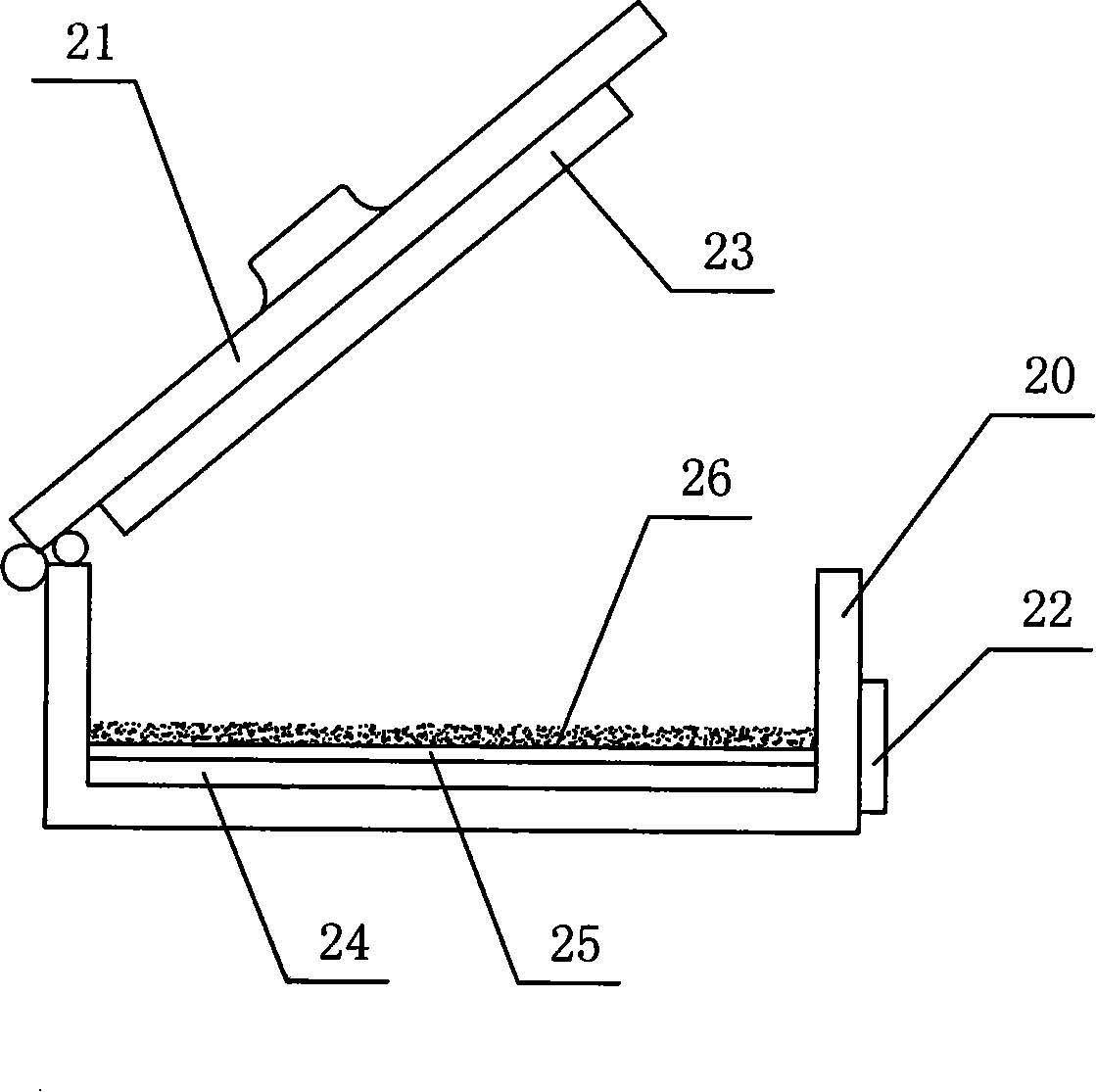

[0056] (c) High-temperature step-by-step firing: ①Place the dried semi-finished glass painting on the figure 2 On the high-temperature-resistant gypsum powder 26 of the shown hot melting furnace, heat up, and when the temperature rises to 300°C, keep the temperature constant for 10 minutes; ②Then continue to heat up to 580°C, and keep the temperature constant for 20 minutes; ℃, keep the temperature at this temperature for 20 minutes; ④ then start to cool down, when the temperature in the furnace drops to 680 ...

Embodiment 2

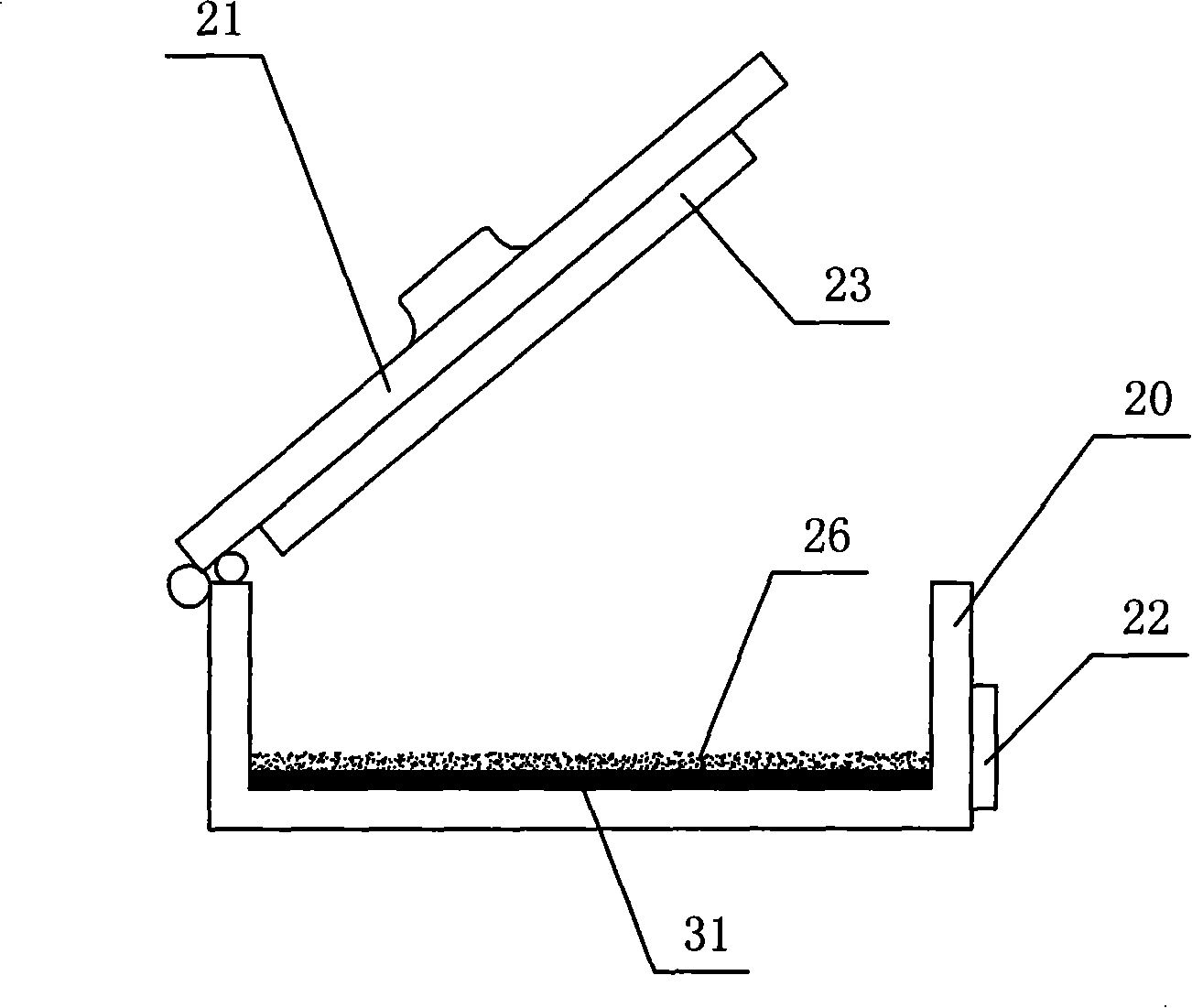

[0059] (a) (b) steps are the same as in Example 1; (c) high-temperature step-by-step firing: 1. put the semi-finished glass painting on the oven dry image 3 On the high-temperature-resistant gypsum powder 26 of the shown hot melting furnace, the temperature is raised to 330°C, and the temperature is kept constant for 6 minutes; ②Then continue to heat up to 650°C, and the constant temperature is 16 minutes; ③Then heat up to 850°C, and the constant temperature is 15 minutes; When the temperature in the furnace drops to 620°C, keep the temperature constant for 6 minutes; ⑤Stop heating, so that the temperature in the furnace will automatically drop to 35°C, and then take it out of the furnace.

Embodiment 3

[0061] (a) (b) steps are the same as in Example 1; (c) high-temperature step-by-step firing: 1. put the semi-finished glass painting on the oven dry Figure 4 On the tin liquid 42 in the tin pool 41 of the shown hot melting furnace, heat up to 280°C and keep the temperature constant for 15 minutes; ②Then continue to heat up to 550°C and keep the temperature constant for 25 minutes; ③Then heat up to 750°C and keep the temperature constant for 25 minutes; Start to cool down, and when the temperature in the furnace drops to 600°C, keep the temperature constant for 8 minutes; ⑤Stop heating, so that the temperature in the furnace will automatically drop to room temperature, and take out the furnace.

[0062] The glass paintings made in Examples 2 and 3 have similar quality to the glass paintings made in Example 1. After being placed outdoors for 12 months, the color of the picture pattern is still very bright, not sticky to dust, and does not fade or fade after washing and soaking. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com