B1-level spray coating type polyurethane modified polyisocyanurate foams

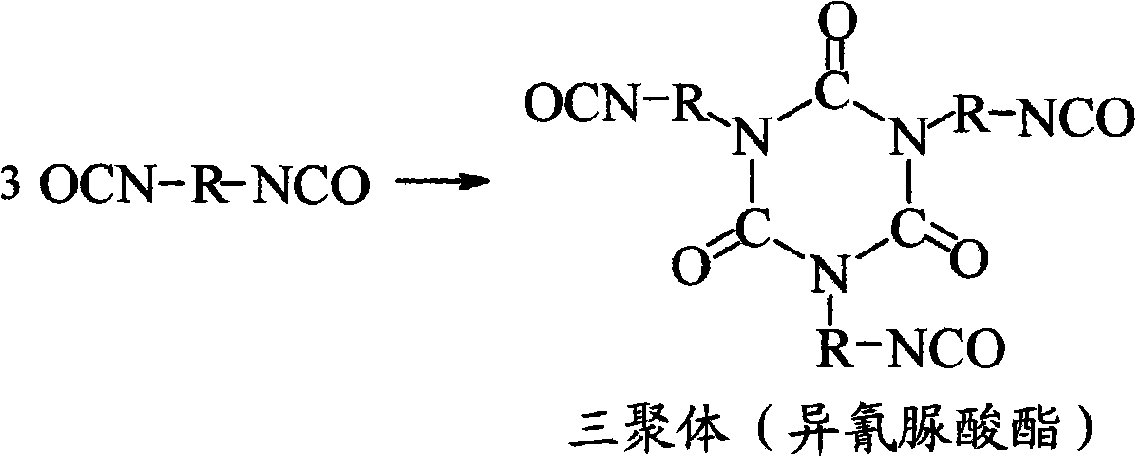

A technology for modifying polyisocyanurate and polyurethane, which is applied in the field of polyurethane foam plastics and can solve problems that do not belong to the flame-resistant method of foam plastics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The formula of the present invention comprises: polyester polyol, cross-linking agent, surfactant, water, catalyst, flame retardant, blowing agent, isocyanate, polyurethane rigid foam is configured as follows in proportion by weight unit:

[0042] Polyester polyol PS-2412: 50-70kg

[0043] Polyester polyol PS-2412: 50-70kg

[0044] Polyether polyol 4110: 35-20kg

[0045] Polyether polyol 403: 15-10kg

[0046] Cross-linking agent: 6-7kg

[0047] Surfactant: 1.5-2kg

[0048] Water: 0.5-1kg

[0049] Composite amine catalyst: 2-3kg

[0050] Alkali metal salt catalyst (potassium acetate): 1-2.5kg

[0051] PZA (hexahydrotriazine): 0.5-1kg

[0052] Composite flame retardant (DMMP / TCPP): 23-24kg

[0053] Blowing agent 141b: 35-38kg

[0054] Mix it evenly, and then take the isocyanate solvent with a weight ratio of PAPI 210-212kg, pump the two into the spray gun from two pumps, mix and spray.

[0055] Among them, the composite flame retardant DMMP and TCPP are configur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com