Two-vat opposed straight-line compressor

A linear compressor, linear technology, applied in the direction of electromechanical devices, mechanical equipment, machines/engines, etc., to achieve the effect of simplifying component assembly accuracy requirements, simplifying processing, and easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

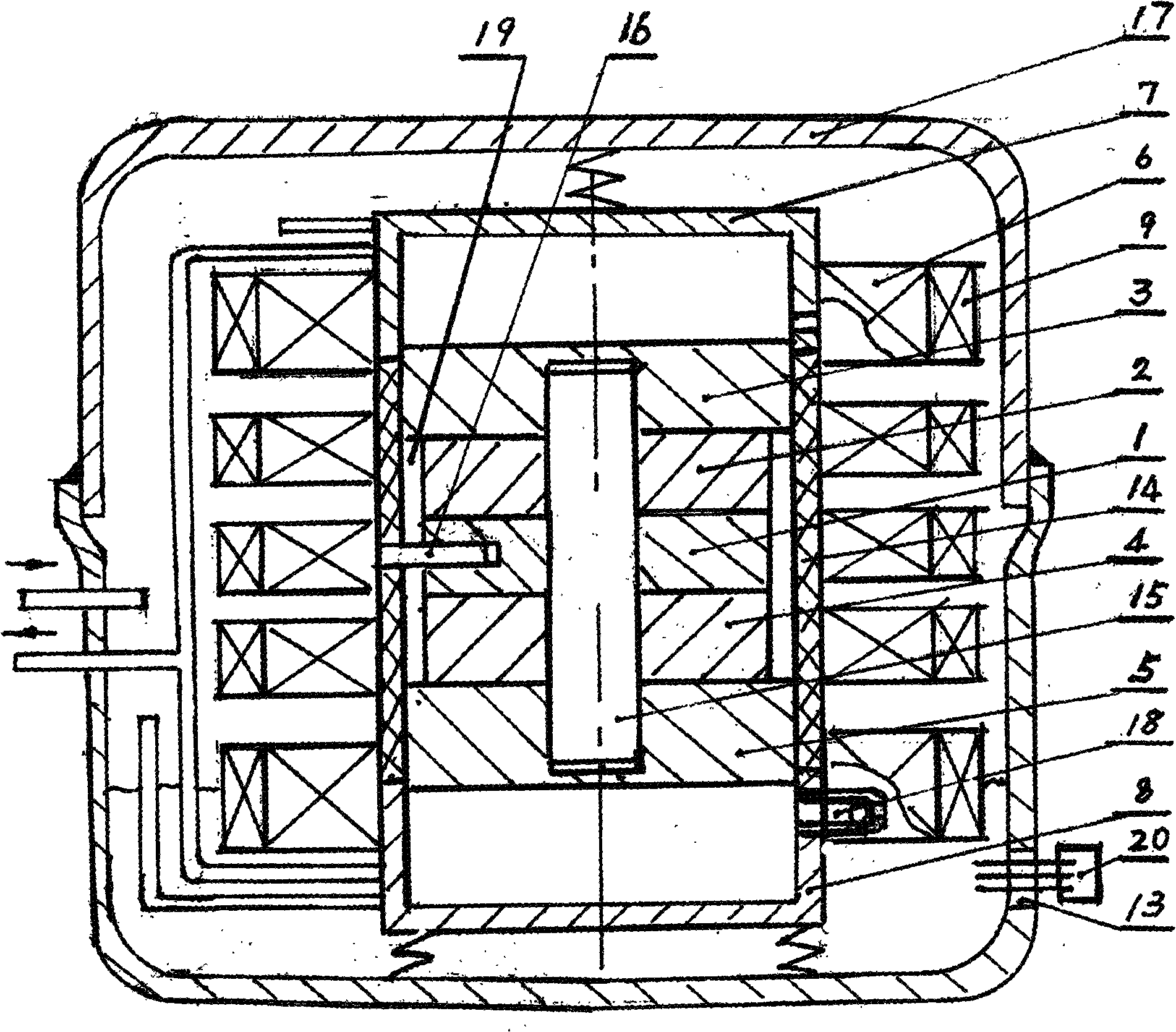

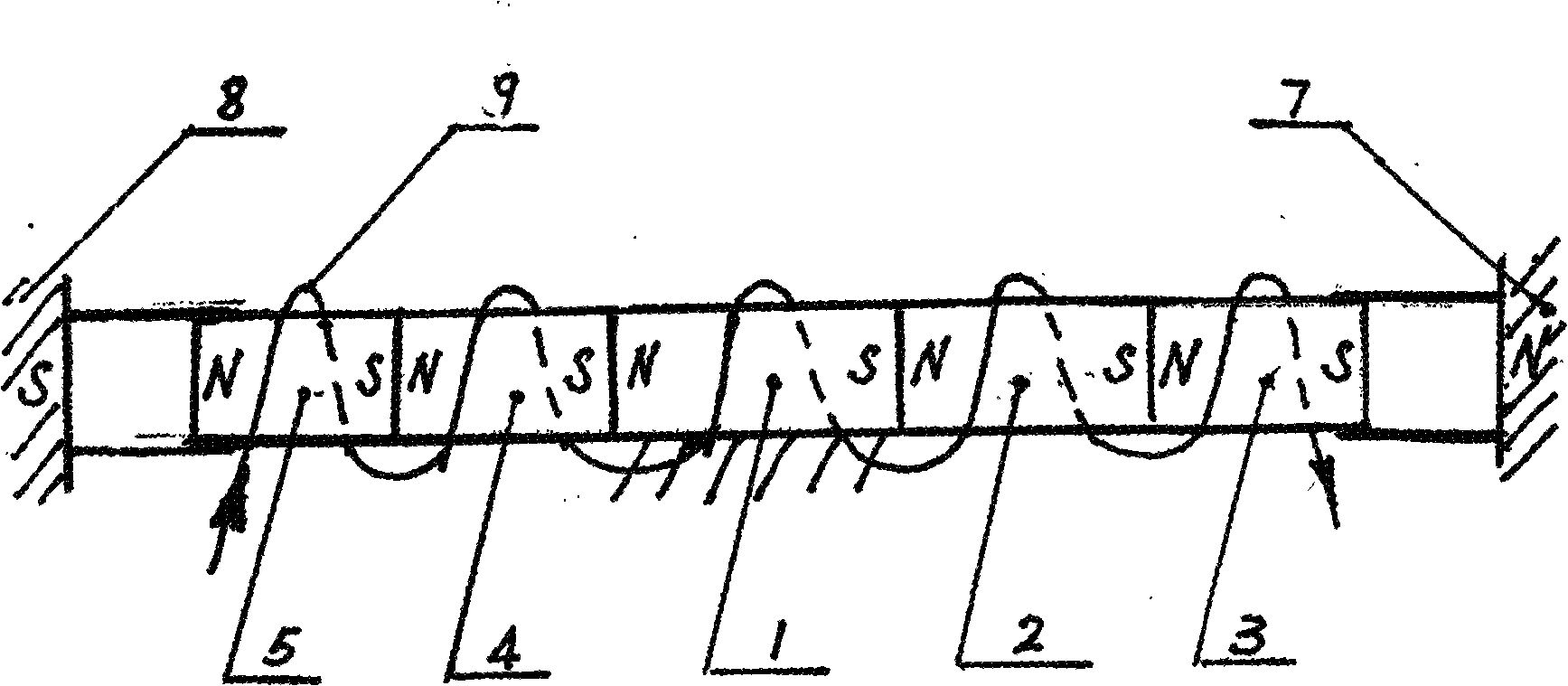

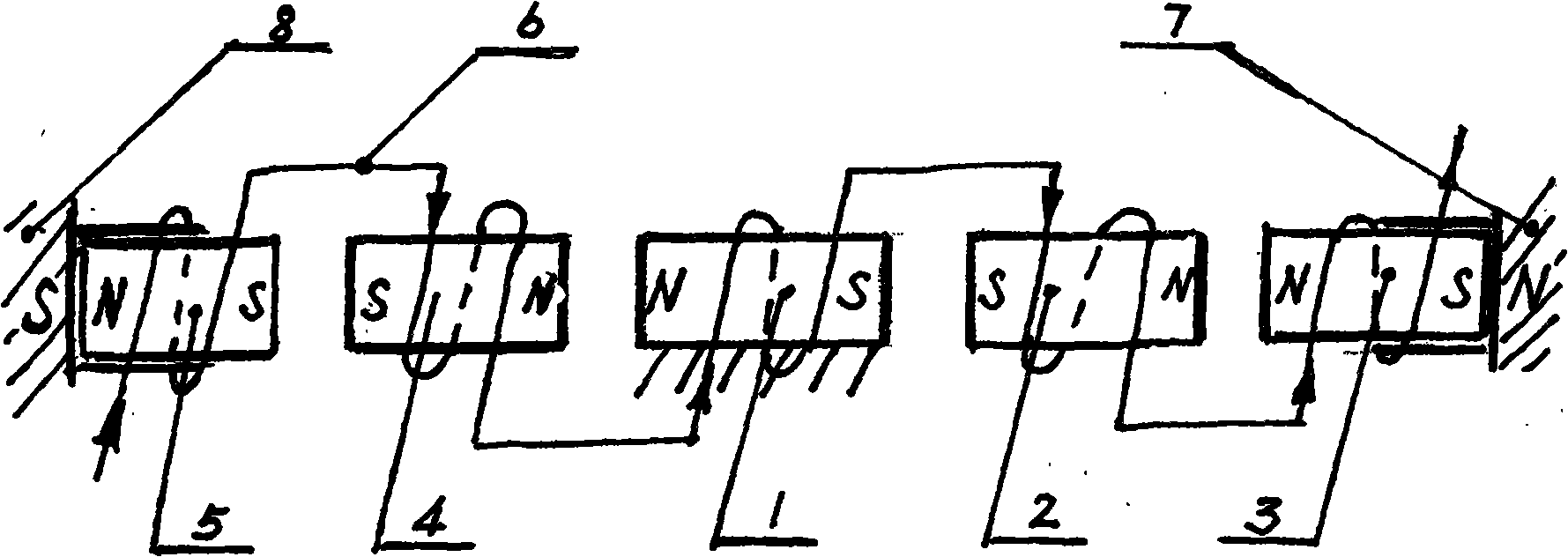

[0014] The following is based on figure 1 , figure 2 , image 3 , Figure 4 An embodiment of the present invention is given to better illustrate the principles, structural features and functional features of the present invention, rather than to limit the protection scope of the present invention. There are also many implementation modes, and the present invention can be implemented in a single cylinder Compressor, single or bidirectional linear motor, single or bidirectional electromagnet manufacture, application and control.

[0015] figure 1 Among them, in the sealed casing 17, the two ends of the linear solenoid motor 19 are concentric and vertical and the upper cylinder 7 and the lower cylinder 8 are installed oppositely. The hole of the bobbin 14 is processed concentrically with the hole of the upper cylinder 7 and the hole of the lower cylinder 8, and the holes are sequentially filled with the lower piston armature 5, the lower armature 4, the fixed armature 1, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com