Stack-press device

A pressure-bearing ring and mounting hole technology, which is applied in the field of lamination devices, can solve the problems of unable to produce stators, small construction space, and inability to carry out welding work, so as to achieve the effects of convenient welding, avoiding oil leakage, and facilitating installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

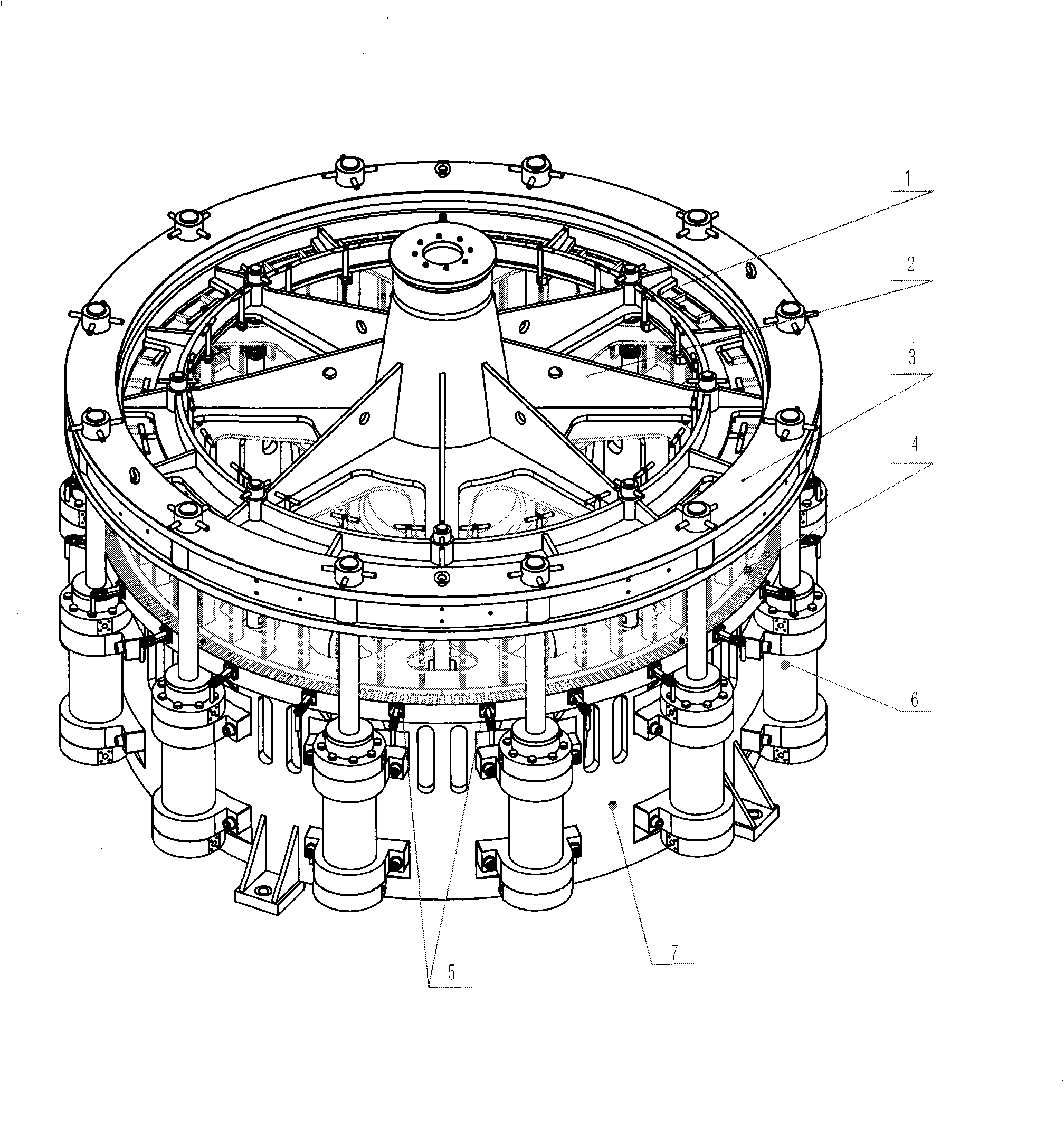

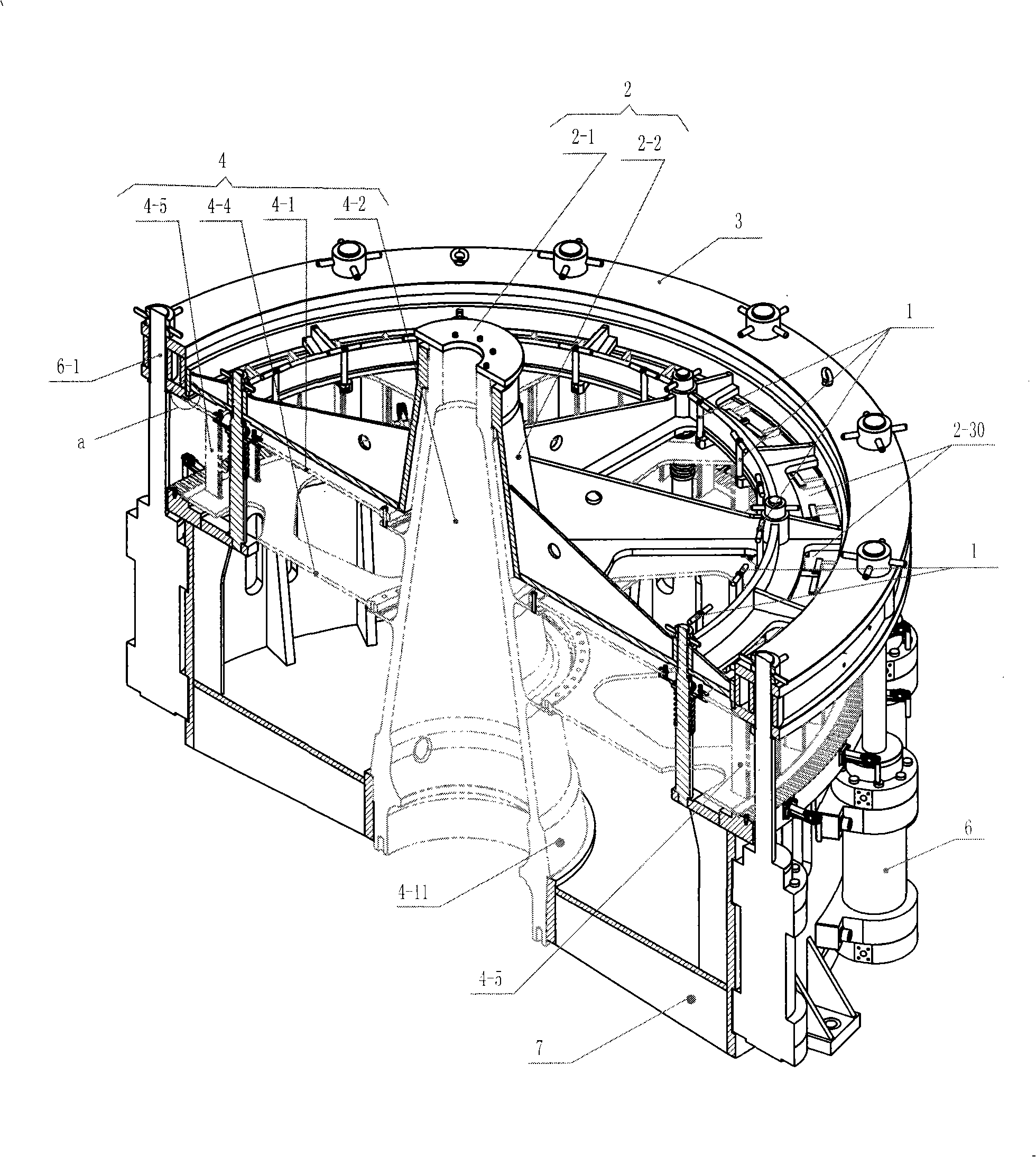

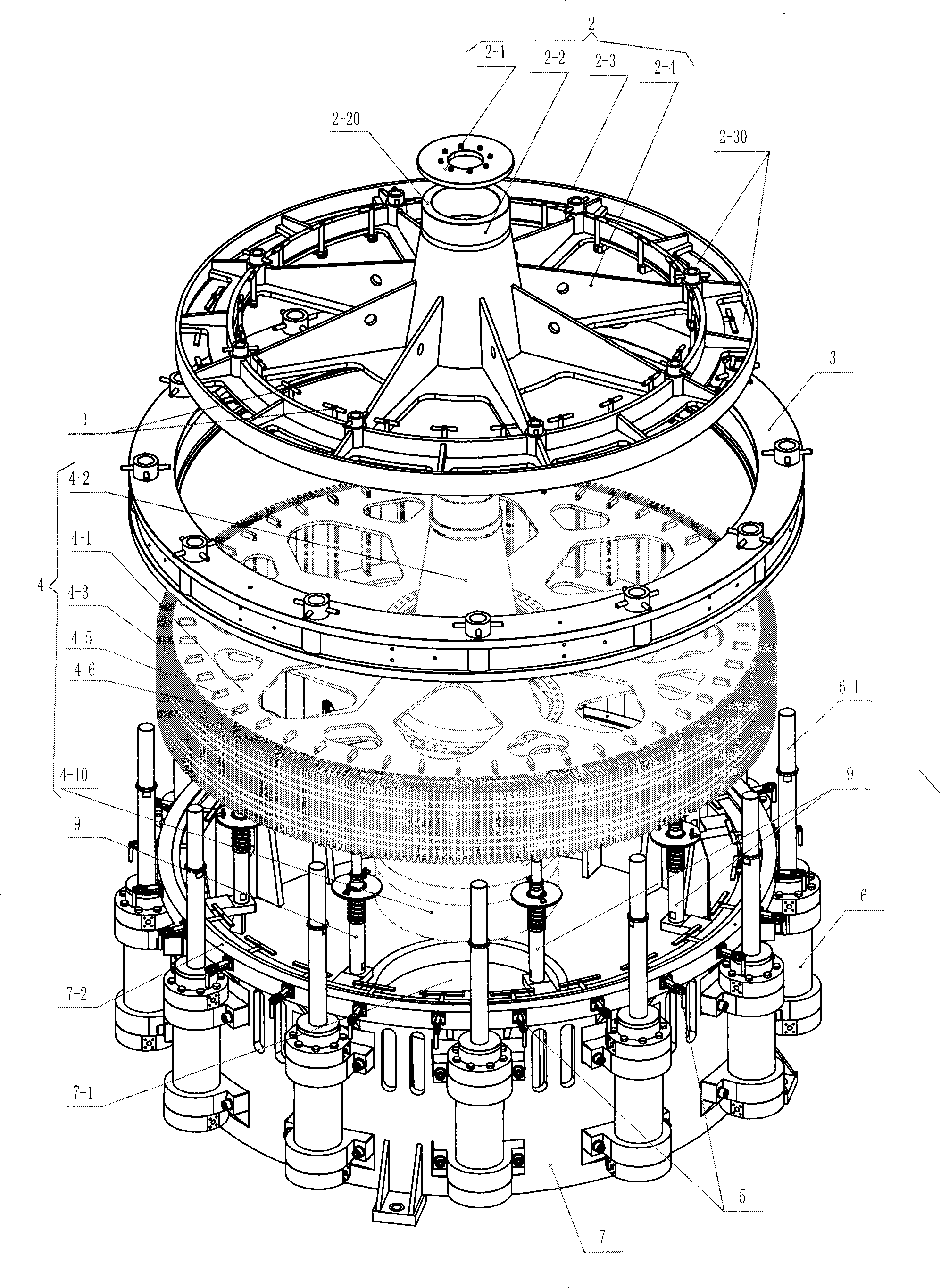

[0022] See Figure 1-3 , The laminating device of this embodiment includes: a base 7 , 12 pull-down oil cylinders 6 evenly distributed on the outer wall of the base 7 , a pressure bearing ring 3 and an upper cover 2 . Oil cylinder 6 is a heavy-duty oil cylinder.

[0023] When in use, the base 7 is provided with the main shaft 4-2 of the stator 4 to be laminated, and the main shaft 4-2 is provided with a disc-shaped front end plate 4-1 and a rear end plate 4-4 correspondingly arranged up and down. , the silicon steel sheet 4-3 of the stator 4 is arranged between the front end plate 4-1 and the rear end plate 4-4; the pressure ring 3 and the upper cover 2 are used to be arranged above the front end plate 4-1 of the stator 4 , and the upper cover 2 is located on the inner side of the pressure ring 3; 12 installation holes are evenly distributed on the pressure ring 3, the cylinder body of each oil cylinder 6 is fixed on the outer wall of the base 7, and the piston rod 6- 1 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com