Method for processing ring extension of cooker

A processing method and technology for pots and pans are applied in the processing field of stainless steel heightening rings, which can solve the problems of low utilization rate of bottom wafers, waste of materials and high cost, and achieve the effects of material saving, cost reduction and material saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

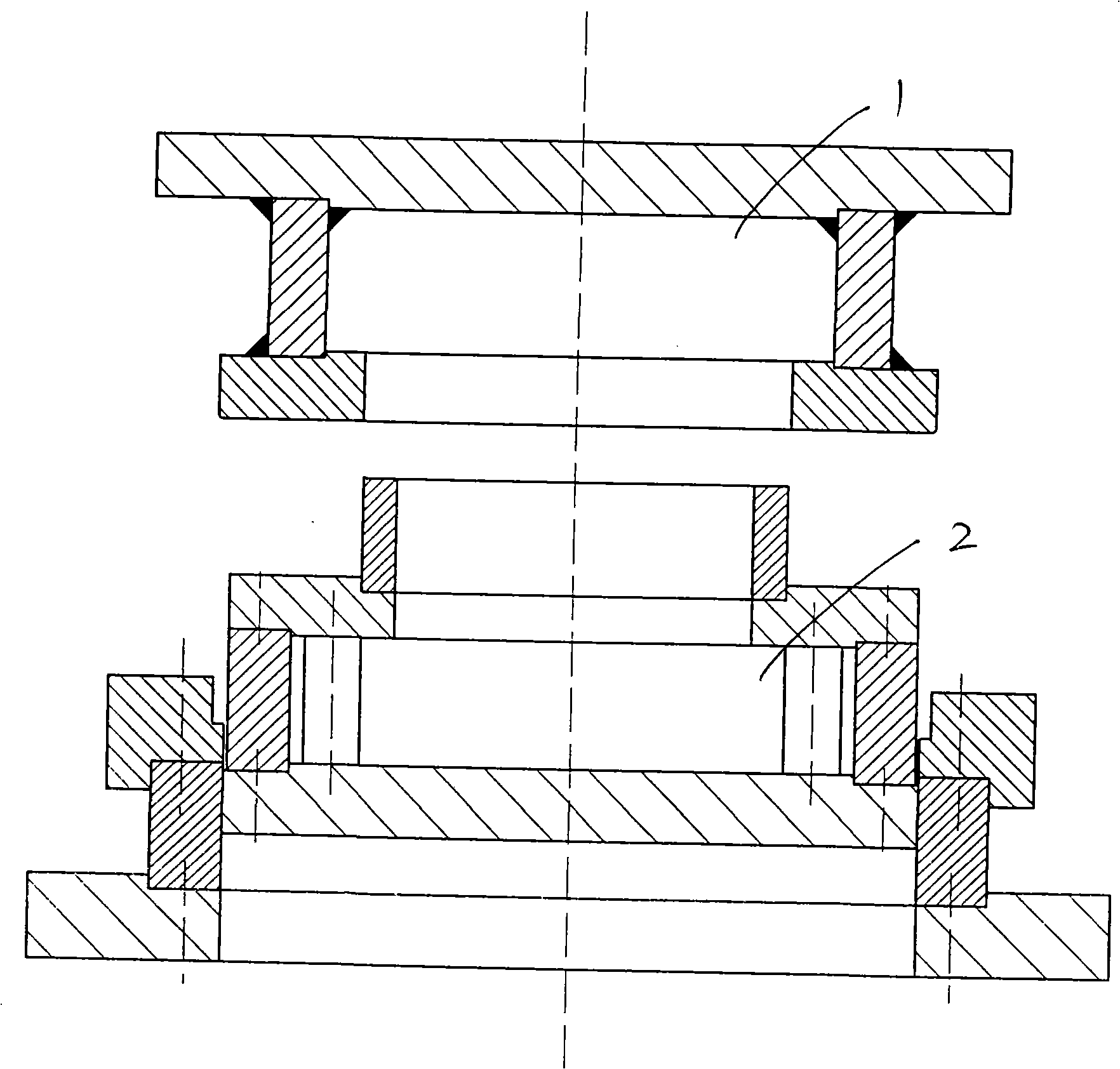

[0017] In order to save materials and reduce costs, the processing method to be provided by the present invention is not to use a circular sheet to stretch and form it, and then wash away the bottom to form a loop, but to directly weld the strip to form a loop according to the specific requirements of the heightened loop size. , after bulging and starting, and then curling. With reference to the accompanying drawings, specifically include

[0018] 1) Slicing, cutting the plate into strips as required.

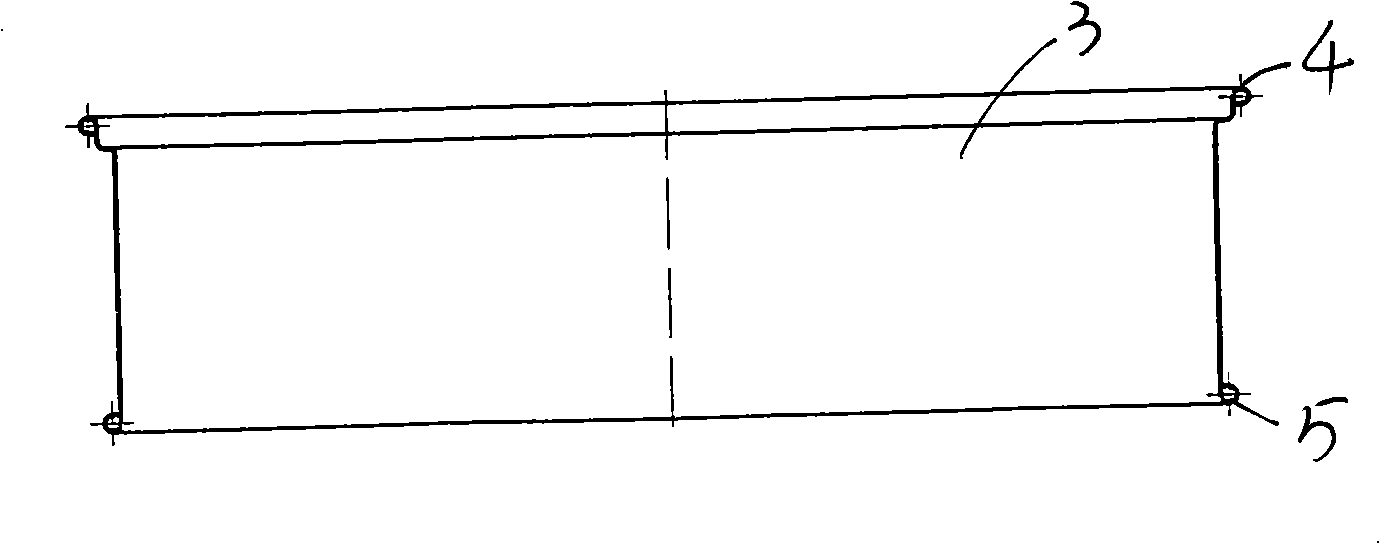

[0019] 2) Seam welding to form a circle, the strip-shaped steel material is rolled into a circle and then seam-welded to form a cylindrical circle 3 .

[0020] 3) Bulging starting stage, in the technical field, welded into circles with strips, when stretching and bulging, because there is no effect of the anchor shape played by the bottom, it is easy to cause wrinkling when bulging is starting and deformation. In this regard, the inventor improves the existing bulging starti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com