Shuttering component

A formwork member and component technology, applied in the field of formwork members, can solve problems such as damage to formwork members, poor overall strength and rigidity of formwork members, and inability to cast-in-situ concrete hollow floor under force and transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

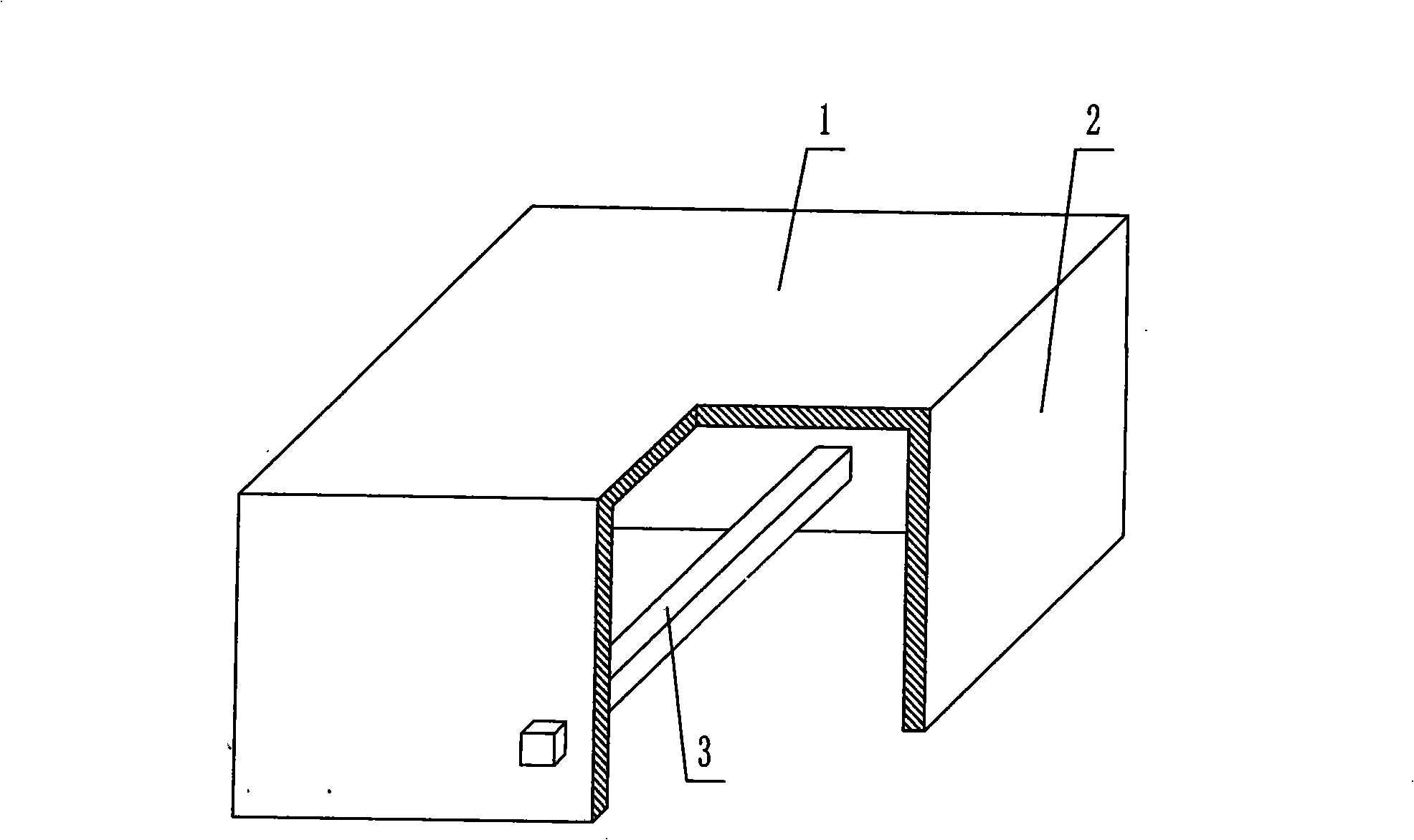

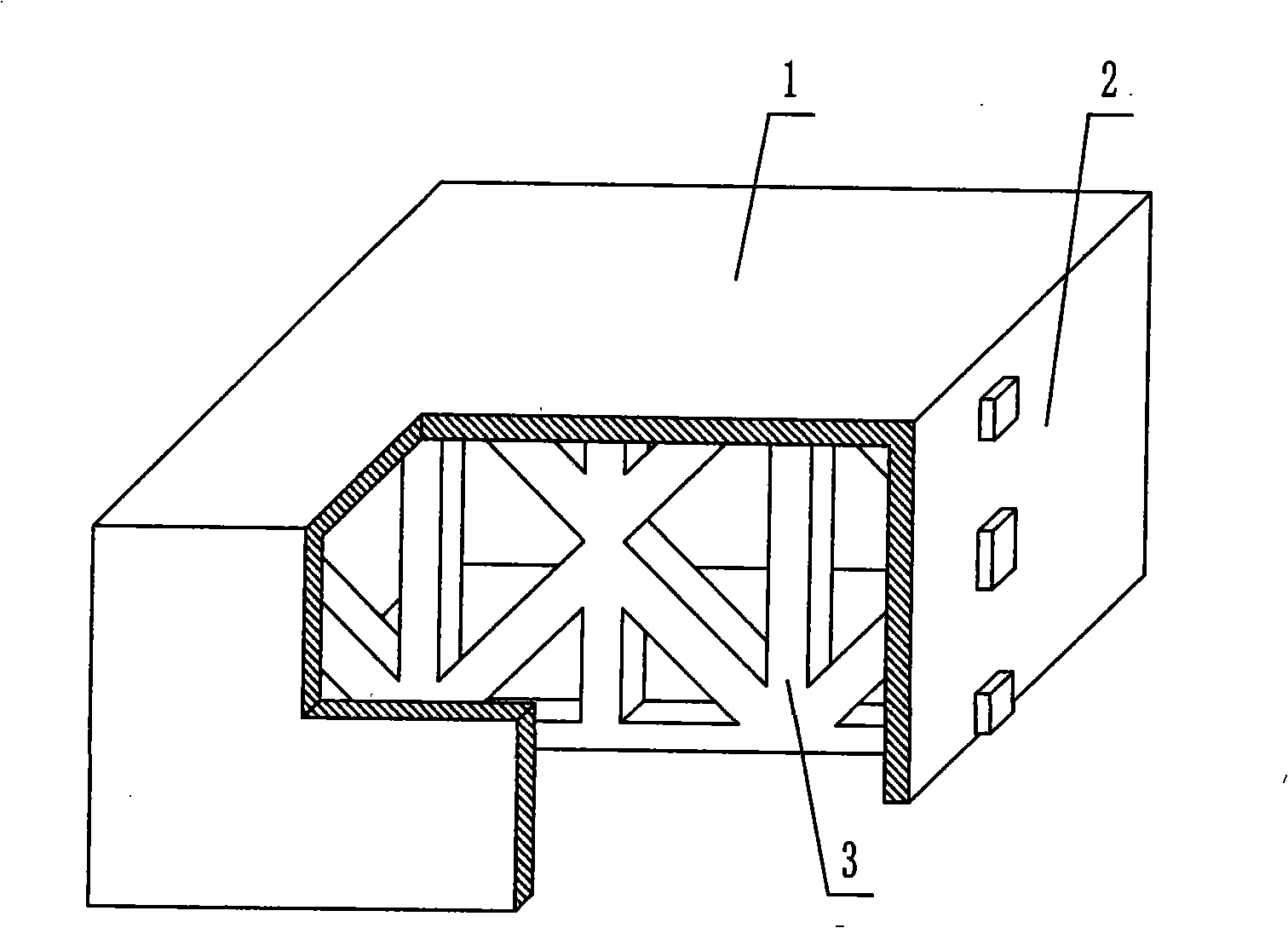

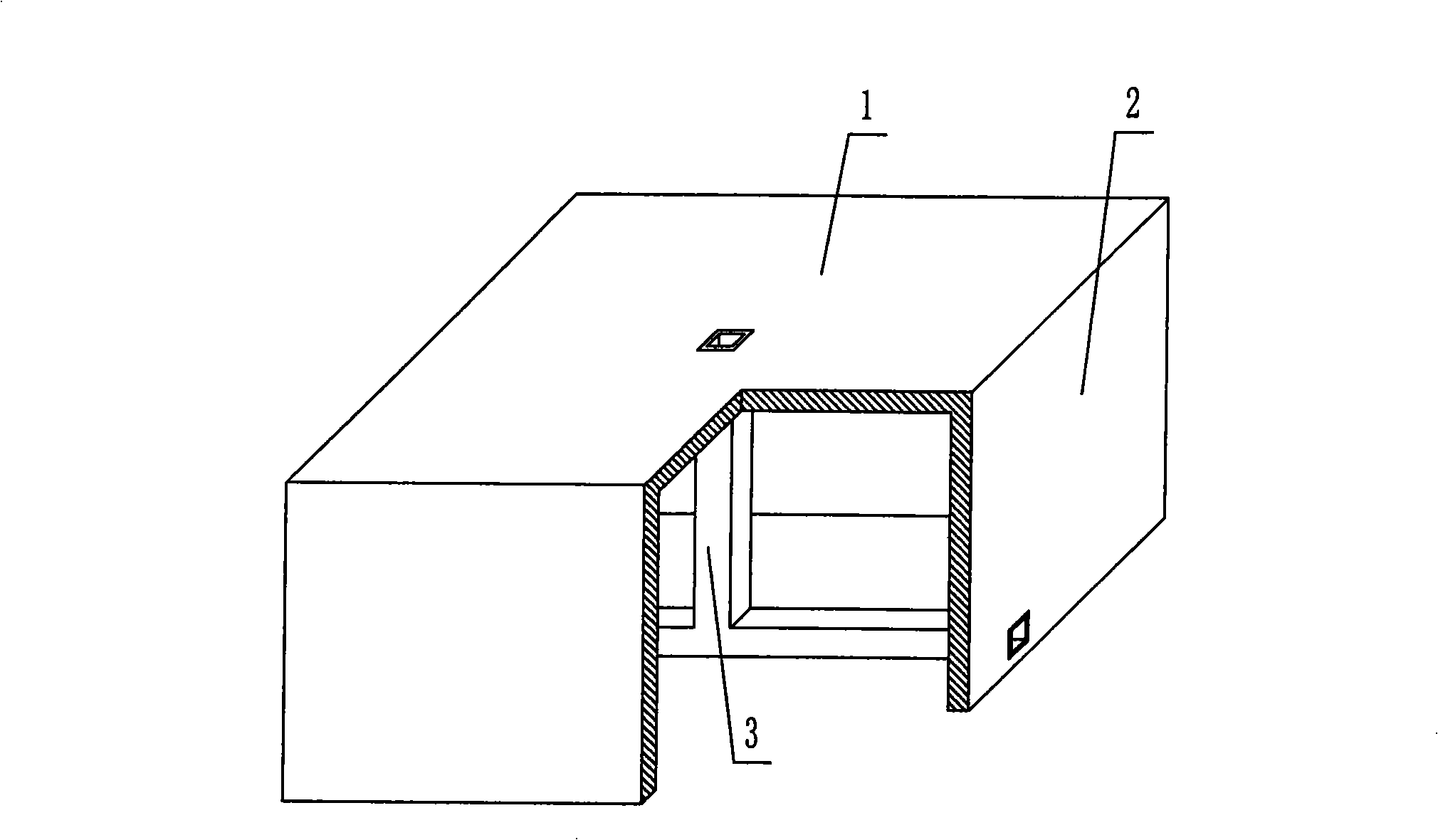

[0051] As shown in the accompanying drawings, the present invention includes an upper plate 1 and surrounding side walls 2, and the upper plate 1 and the surrounding side walls 2 form an open basin-shaped member, which is characterized in that the cavity of the basin-shaped member is provided with The stiffener 3 is integrated with the basin-shaped member, and the formwork member is also provided with reinforcing ribs 19 or stiffening ribs 20 or reinforcing cables 21 . figure 1 It is a structural schematic diagram of Embodiment 1 of the present invention. In each accompanying drawing, 1 is an upper plate, 2 is a surrounding side wall, and 3 is a stiffener. In the following accompanying drawings, those with the same number have the same description. Such as figure 1 As shown, the upper plate 1 and the surrounding side walls 2 form an open basin-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com