Four-way electromagnetic valve

A four-way valve and electromagnetic technology, which is applied to multi-way valves, valve details, valve devices, etc., can solve the problems of large size, inconvenient assembly, and large volume of electromagnetic four-way valves, and achieve volume reduction, size reduction, and Compact and beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

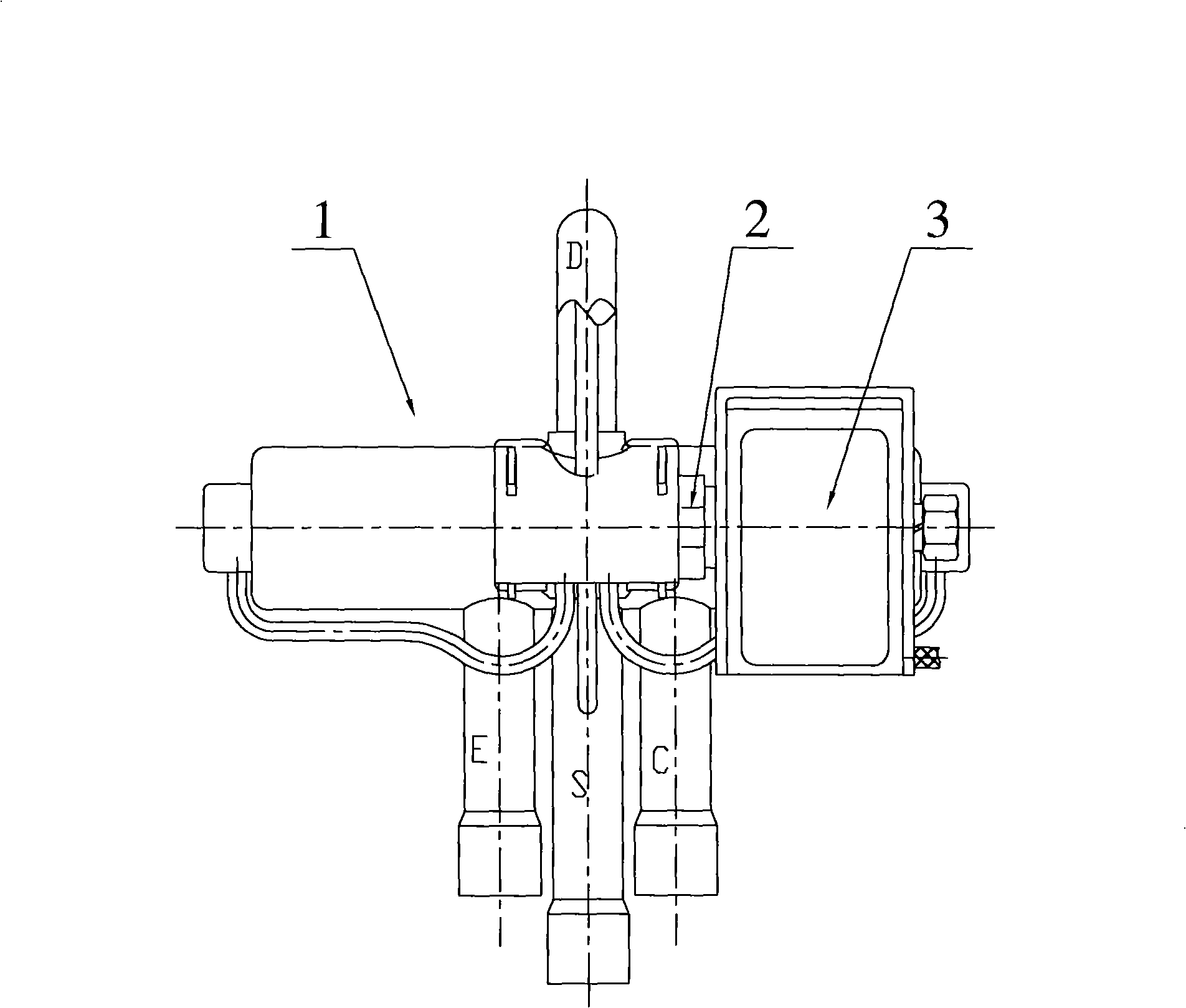

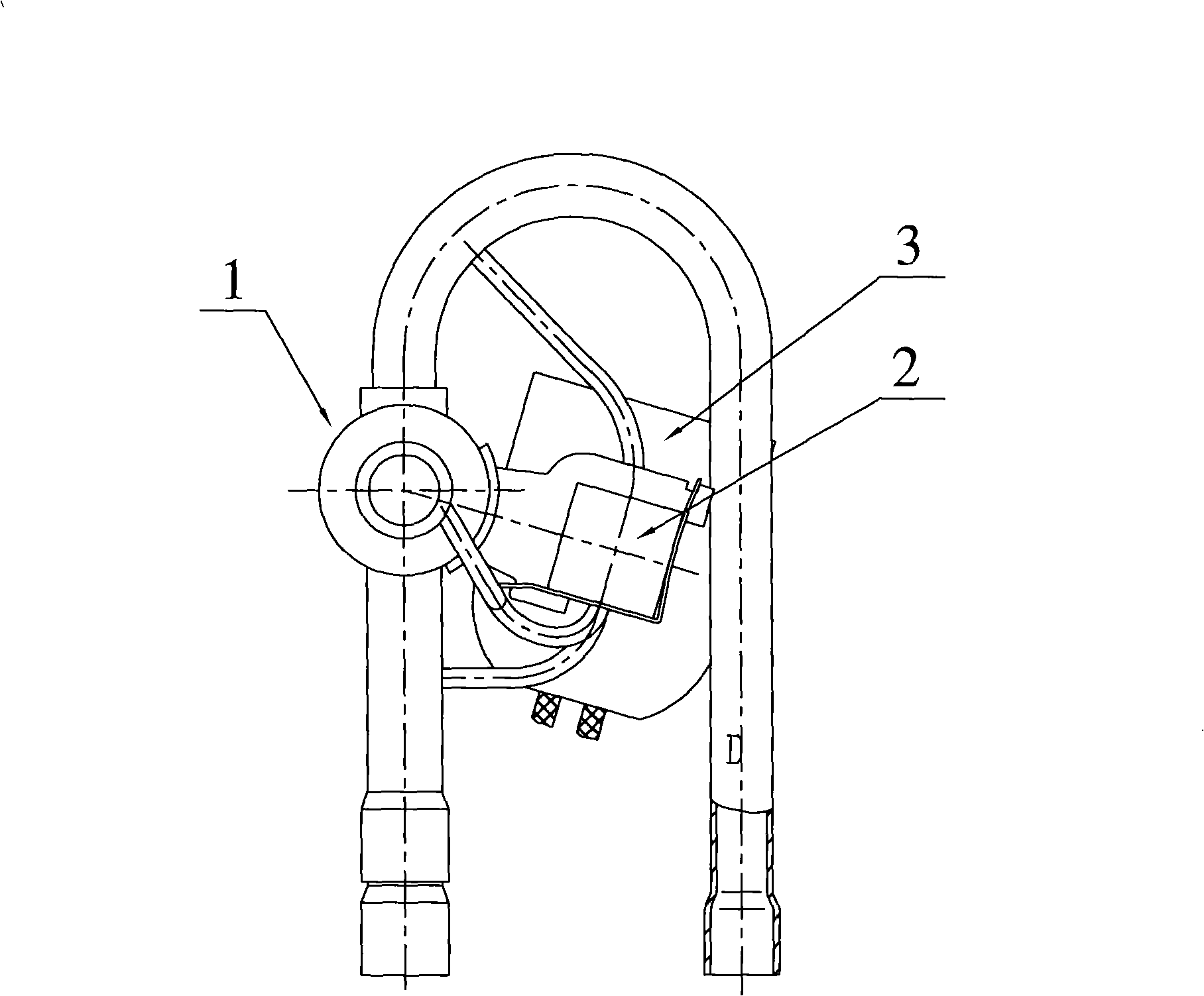

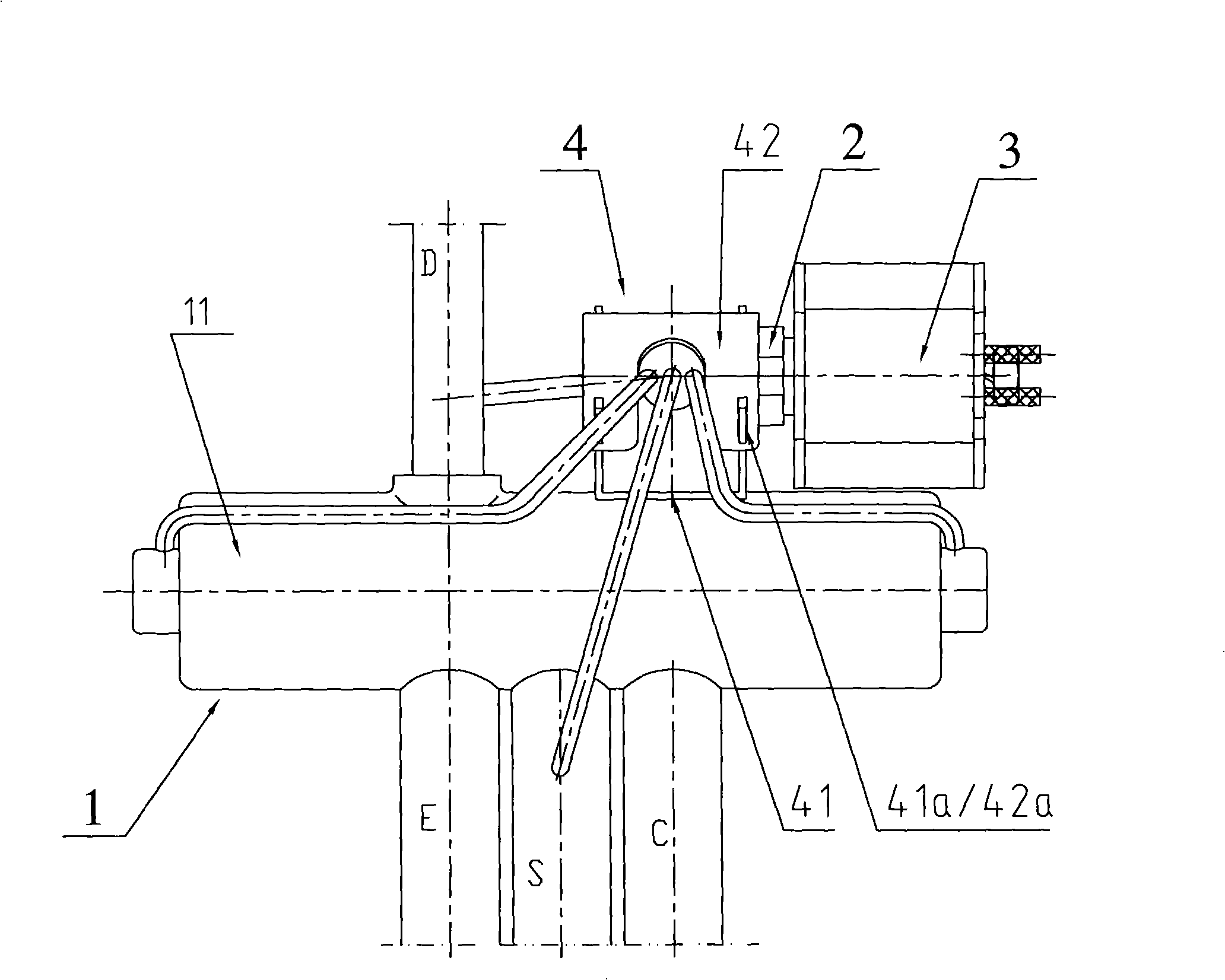

[0021] Such as image 3 , 4 The electromagnetic four-way valve shown includes the same main valve 1, pilot valve 2 and coil 3 as those in the prior art. The upper side of the main valve body 11 is connected with a normally open pipe D extending upward. The main valve body 11 The lower side is connected with the middle connecting pipe S extending downward and two side connecting pipes E / C juxtaposed with the middle taking place;

[0022] also,

[0023] The normally open connecting pipe D deviates from the center position of the main valve body 11 and is located on the left side, so that a large space is left on the right side to install the pilot valve 2 through the bracket assembly 4 and install the coil 3 on the pilot valve 2. The position takeover S is located at the center of the main valve body 11, and the two side takeovers E / C are located on both sides of the middle takeover S;

[0024] The bracket assembly 4 includes two brackets 41 and a card 42 fixed (such as welde...

Embodiment 2

[0027] According to the first embodiment, on the premise that the size of the entire electromagnetic four-way valve in the left and right direction can not be increased, the normally open connecting pipe is located at the center of the main valve body.

Embodiment 3

[0029] According to the specific situation, the central connecting pipe in the first embodiment is arranged off the center line, and then the two side connecting pipes are respectively arranged side by side on both sides of the central connecting pipe.

[0030] The structural changes of the above-mentioned several embodiments do not affect the working principle of the electromagnetic four-way valve, so the working principle will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com