Method for manufacturing thermoplastic polyurethane membrane capable of isolating migration of fabric coloring agent

A thermoplastic polyurethane, fabric dye technology, used in chemical instruments and methods, flat products, lamination, etc., can solve problems such as poor color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

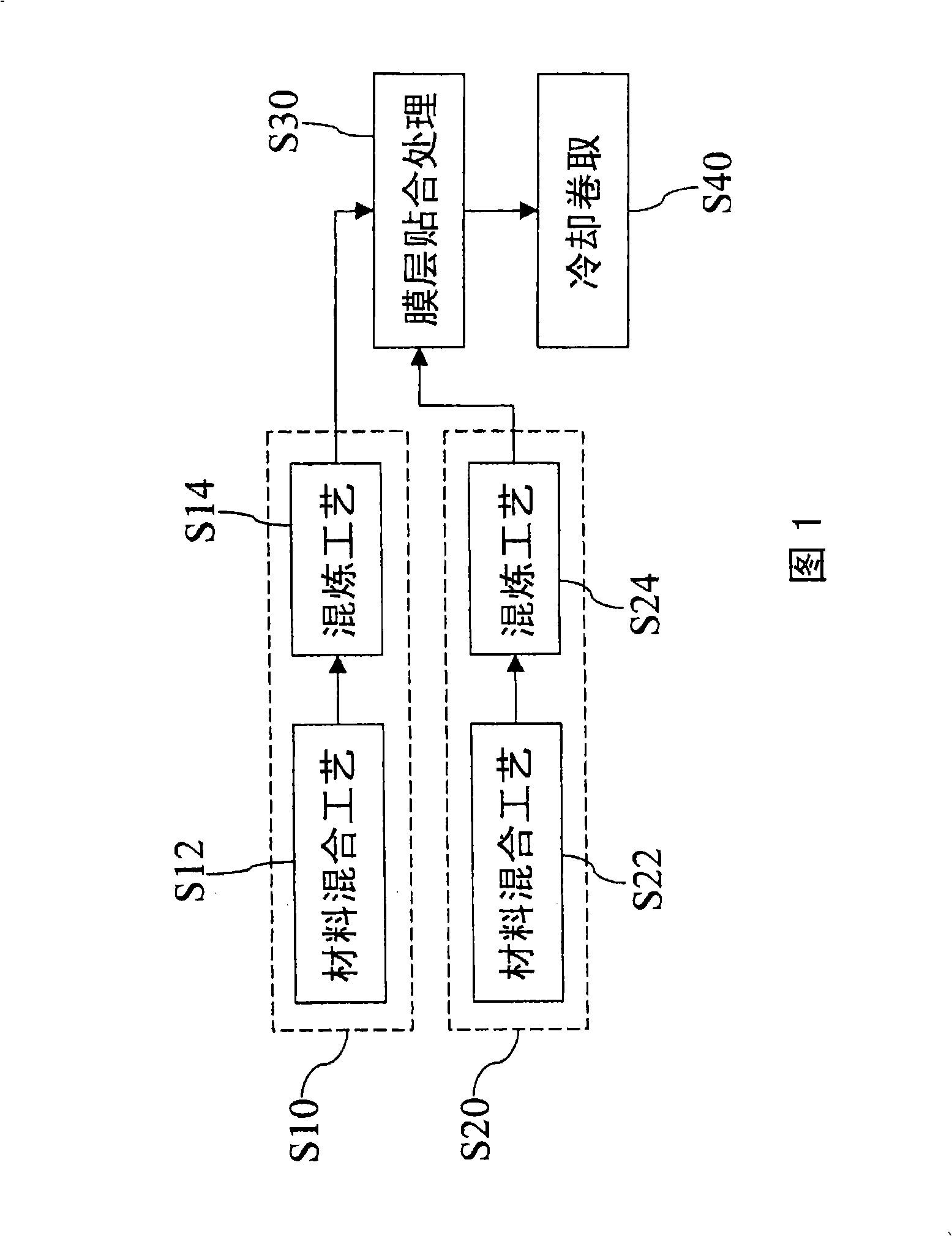

[0030] In the following, specific embodiments are described in detail with reference to the accompanying drawings, so that it is easier to understand the purpose, technical content, features and effects of the present invention.

[0031] The composition of the fabric dye migration barrier thermoplastic polyurethane membrane and its manufacturing method proposed by the present invention are aimed at improving the fabric dye migration problem caused by the high-frequency high-temperature welding and hot-cutting processing of general thermoplastic polyurethane membranes, and completely solve the known thermoplastic polyurethane membrane. The obvious migration phenomenon caused by the high temperature welding of the polyurethane diaphragm and the fabric with poor color fastness.

[0032] The present invention proposes a composition that can be pressed into a fabric dye migration barrier thermoplastic polyurethane film. This composition containing metal powder contains a thermoplast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com