Automatic expansion shaft

An automatic technology for expanding and tightening the shaft, which is applied in printing, rotary printing presses, printing presses, etc., can solve the problems of manual air feeding, and the air expansion shaft depends on the air source, etc., and achieves simple structure, easy operation, and reduced labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

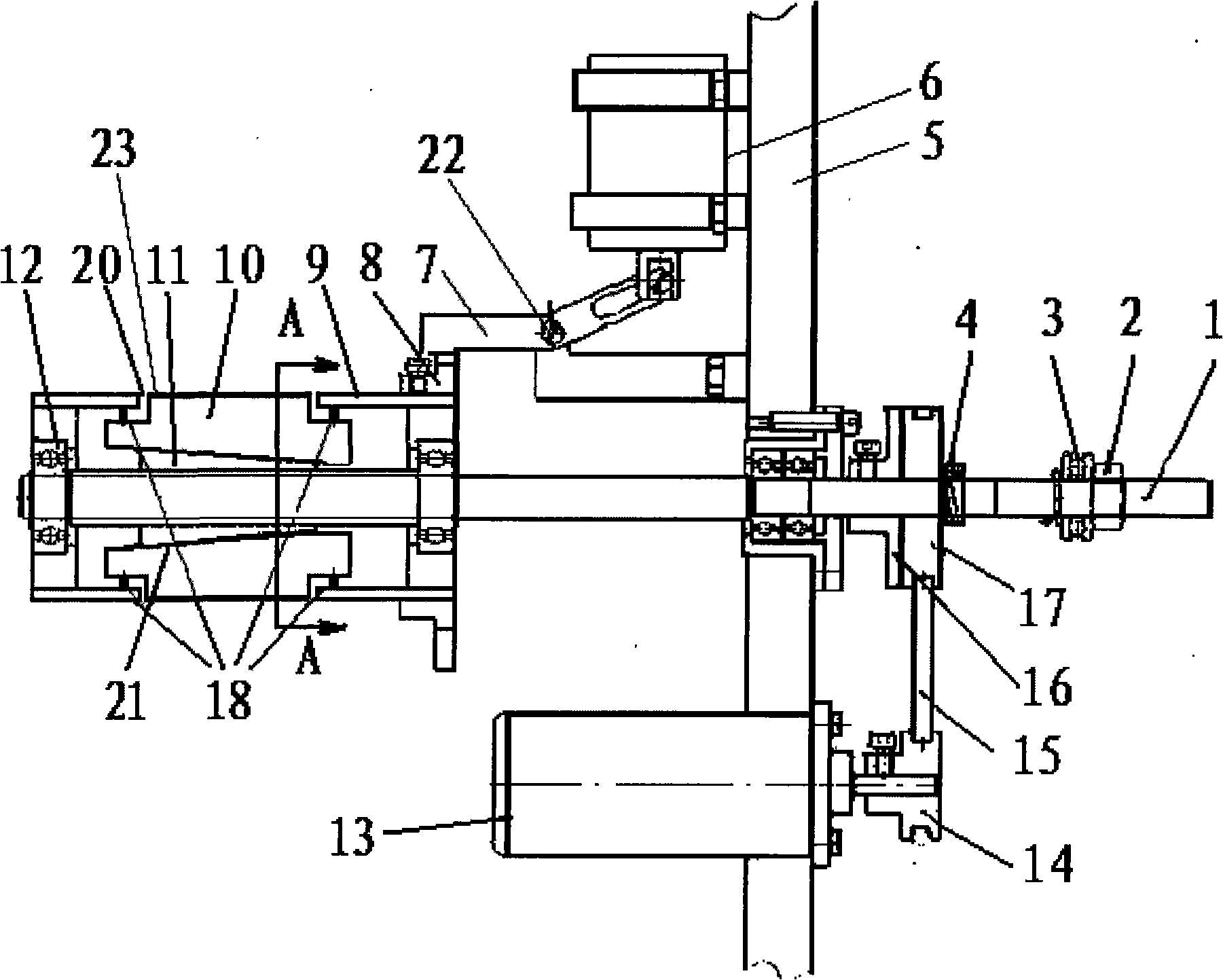

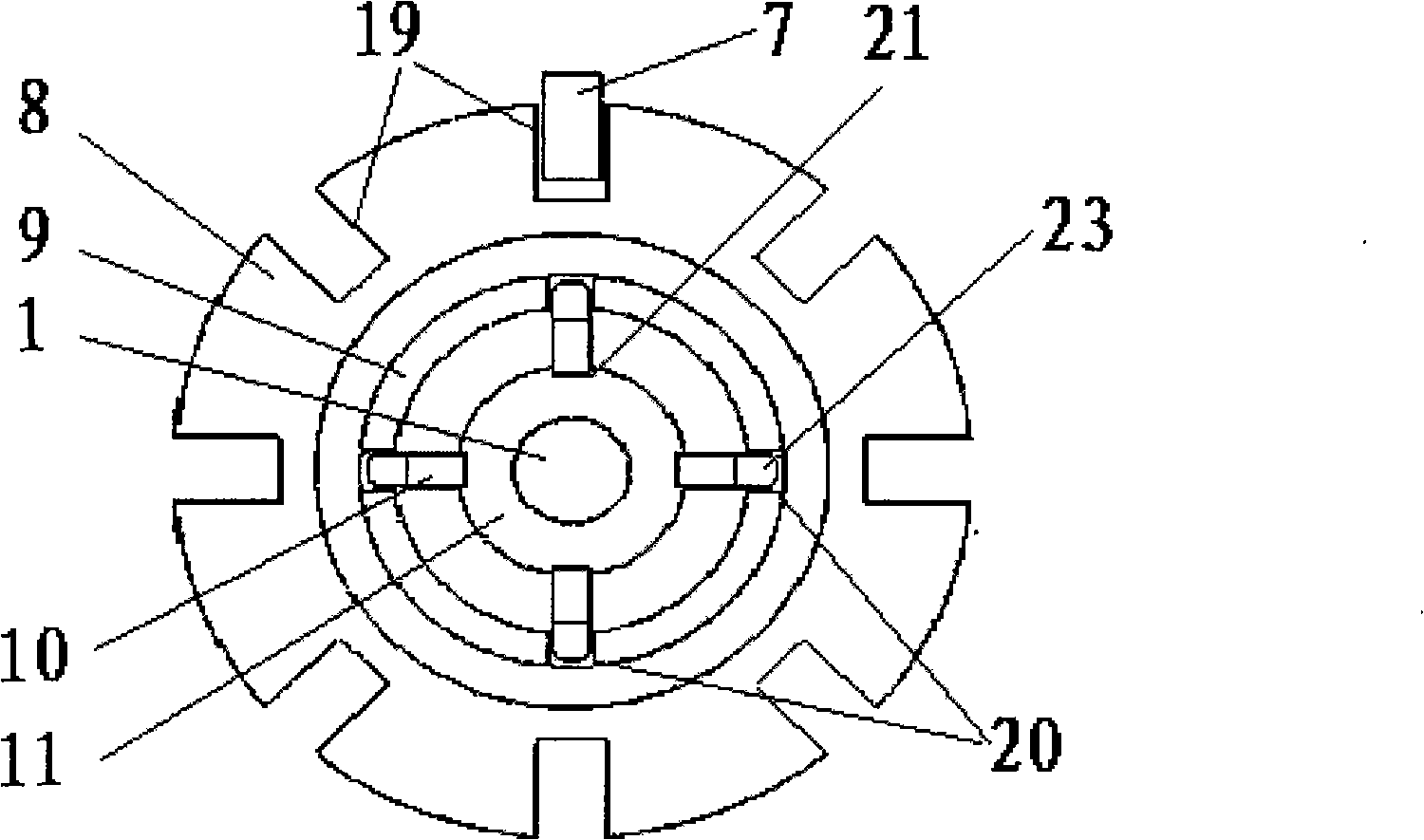

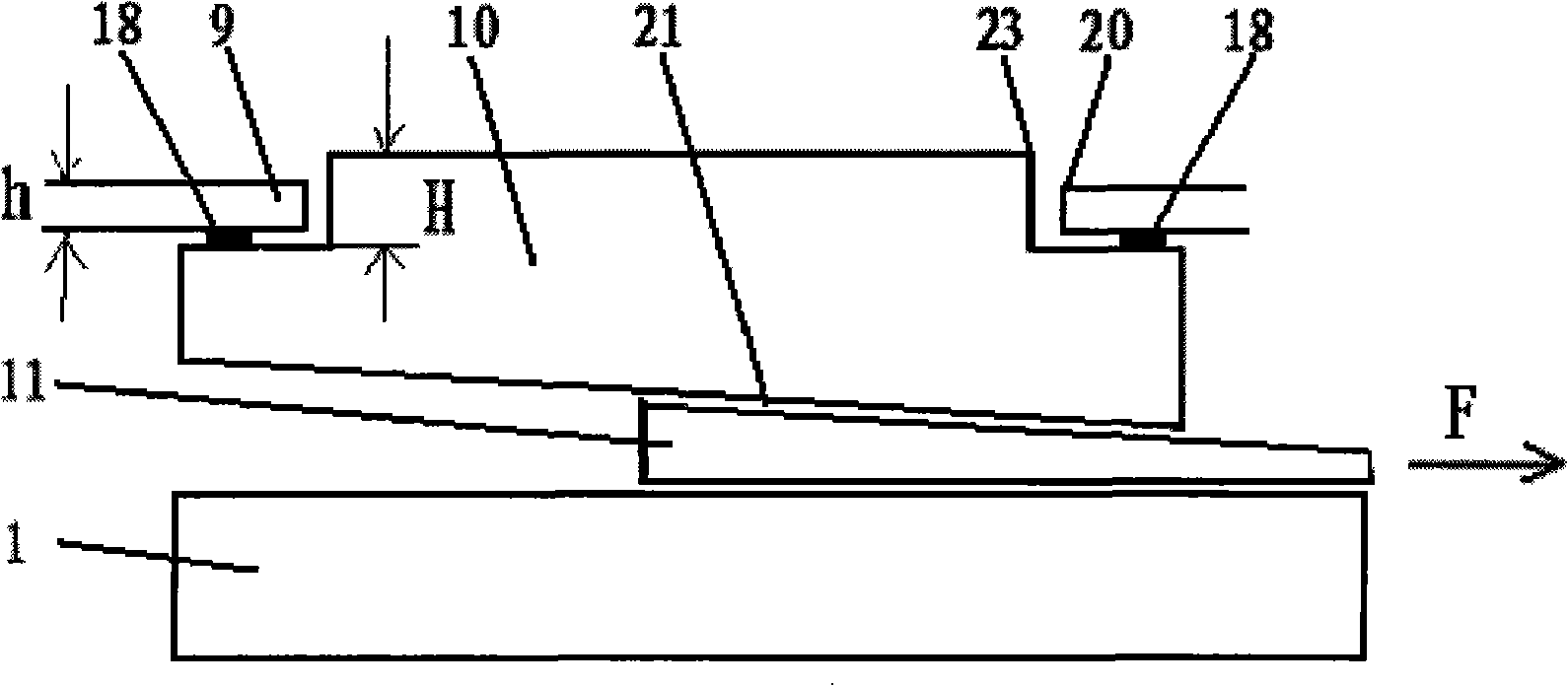

[0016] figure 1 It is a structural schematic diagram of the automatic tensioning shaft of the present invention. It includes a self-expanding part and a driving part, and the driving part is arranged at one end of the lead screw 1, that is, the transmission end, for realizing the rotation of the self-expanding shaft. The driving part includes a lead screw 1, the lead screw 1 is installed through the wallboard 5, the friction wheel 16 is coaxially fixedly installed on the lead screw 1, and a freely rotatable driven wheel 17 is coaxially installed on the lead screw 1, and the driven wheel 17 The compression spring 4 is in surface contact with the friction wheel 16 , and the driven wheel 17 is connected with the transmission wheel 14 of the DC motor 13 through the transmission belt 15 . A thrust bearing 3 and an adjustment nut 2 are installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com