Vehicle body floor structure

A body floor and floor technology, applied in the direction of upper structure, vehicle parts, upper structure sub-assembly, etc., can solve the problems of lowering the floor frame 224, increasing weight, difficult aerodynamic performance, etc., to enhance aerodynamic performance and reduce weight , Increase the effect of internal space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

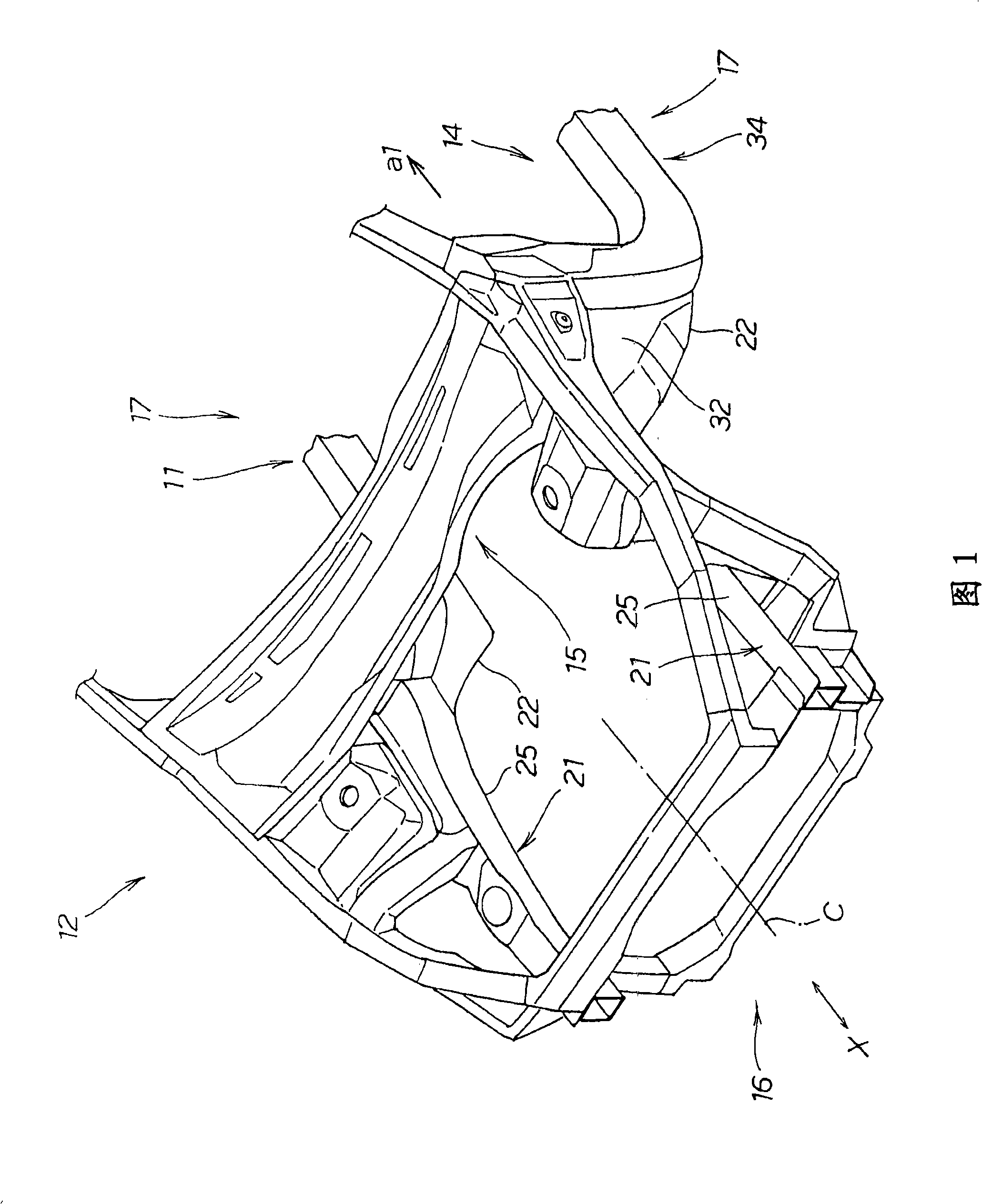

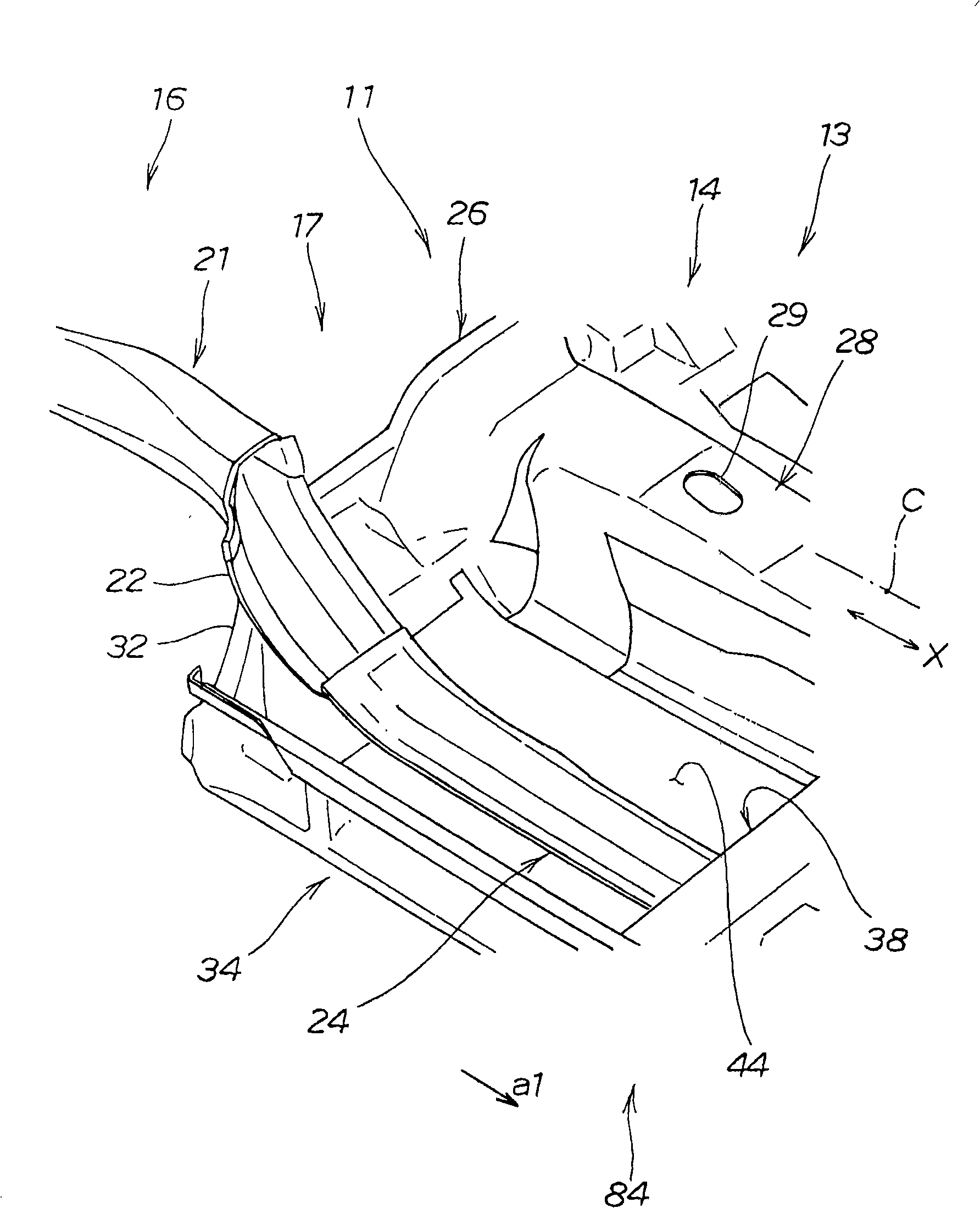

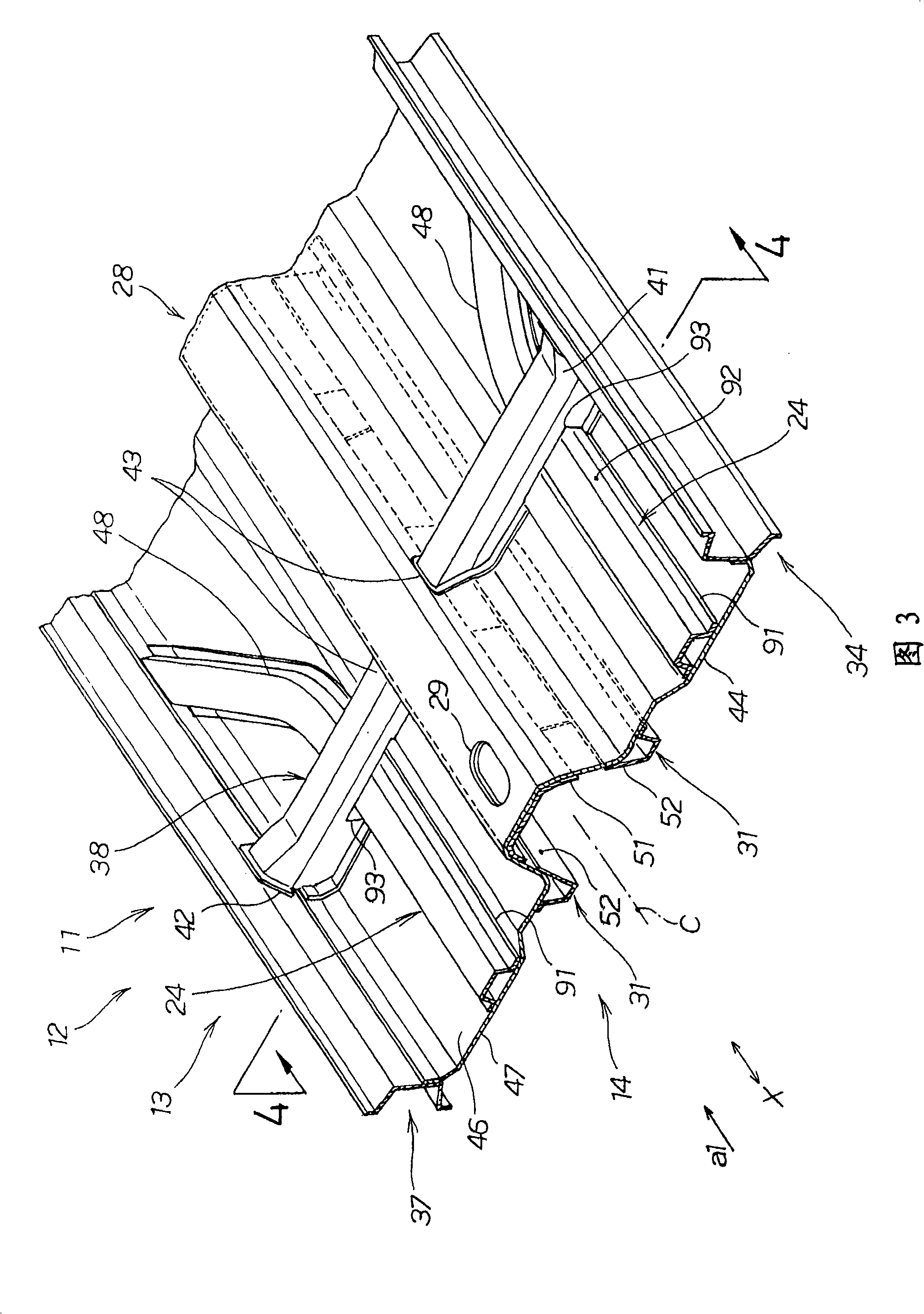

[0040] Referring now to Figure 1 and figure 2 , wherein, FIG. 1 is a perspective view of a front body connected to a vehicle body floor structure according to a first embodiment of the present invention, figure 2 is a perspective view of the front floor frame attached to the body floor structure.

[0041] A vehicle body floor structure 11 is used in a floor body 14 constituting a floor of a compartment 13 of a vehicle 12; the vehicle body floor structure 11 will be discussed in detail later.

[0042] The vehicle 12 includes: a floor main body 14 constituting a floor; a left main body and a right main body 17 constituting the side walls of the compartment 13; a front main body 16 provided at the front of the compartment 13; The compartment 13 is divided by a wall. The left and right side bodies 17 include left side sills 34 and right side sills 37 ( FIG. 3 ), which are connected to the left side of the floor body 14 . and on the right side.

[0043] The front main body 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com