Sticking method of crystalloid resin forming body

A technology of crystalline resin and bonding method, which is applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problems of costing manpower, time, and inefficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

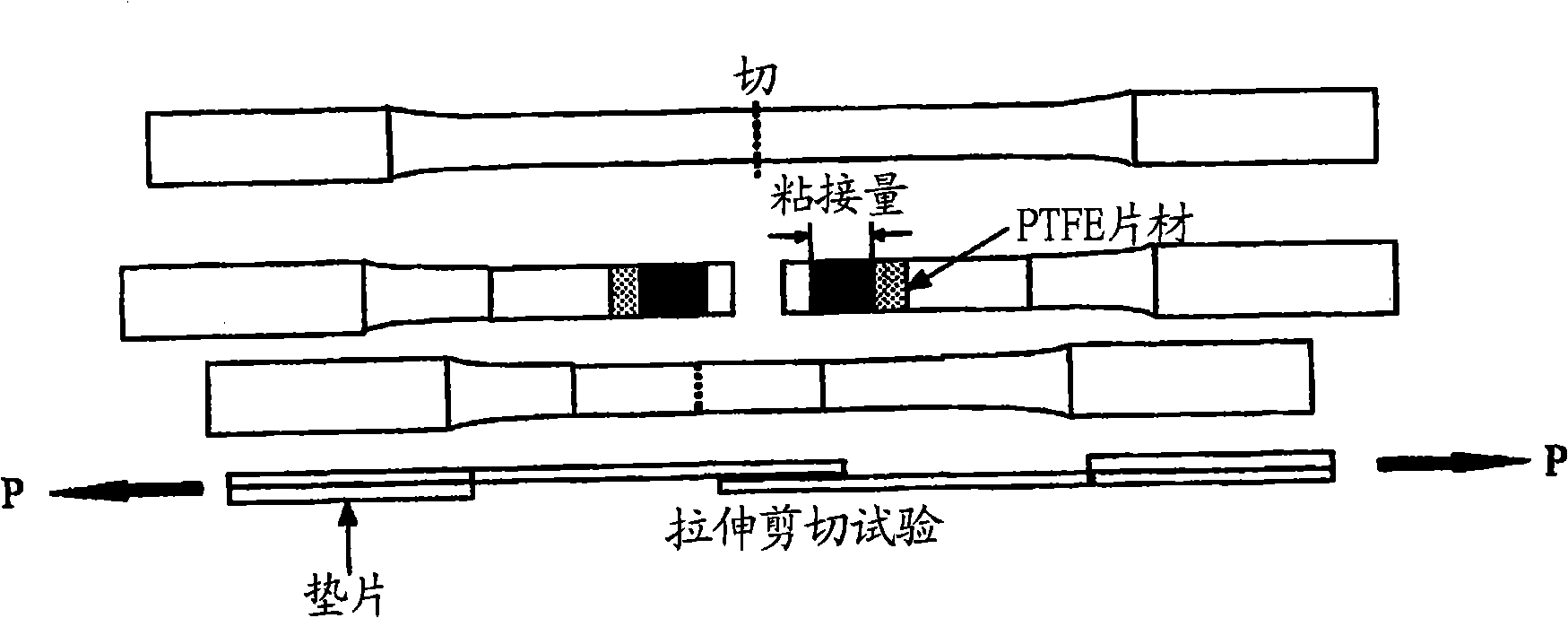

Method used

Image

Examples

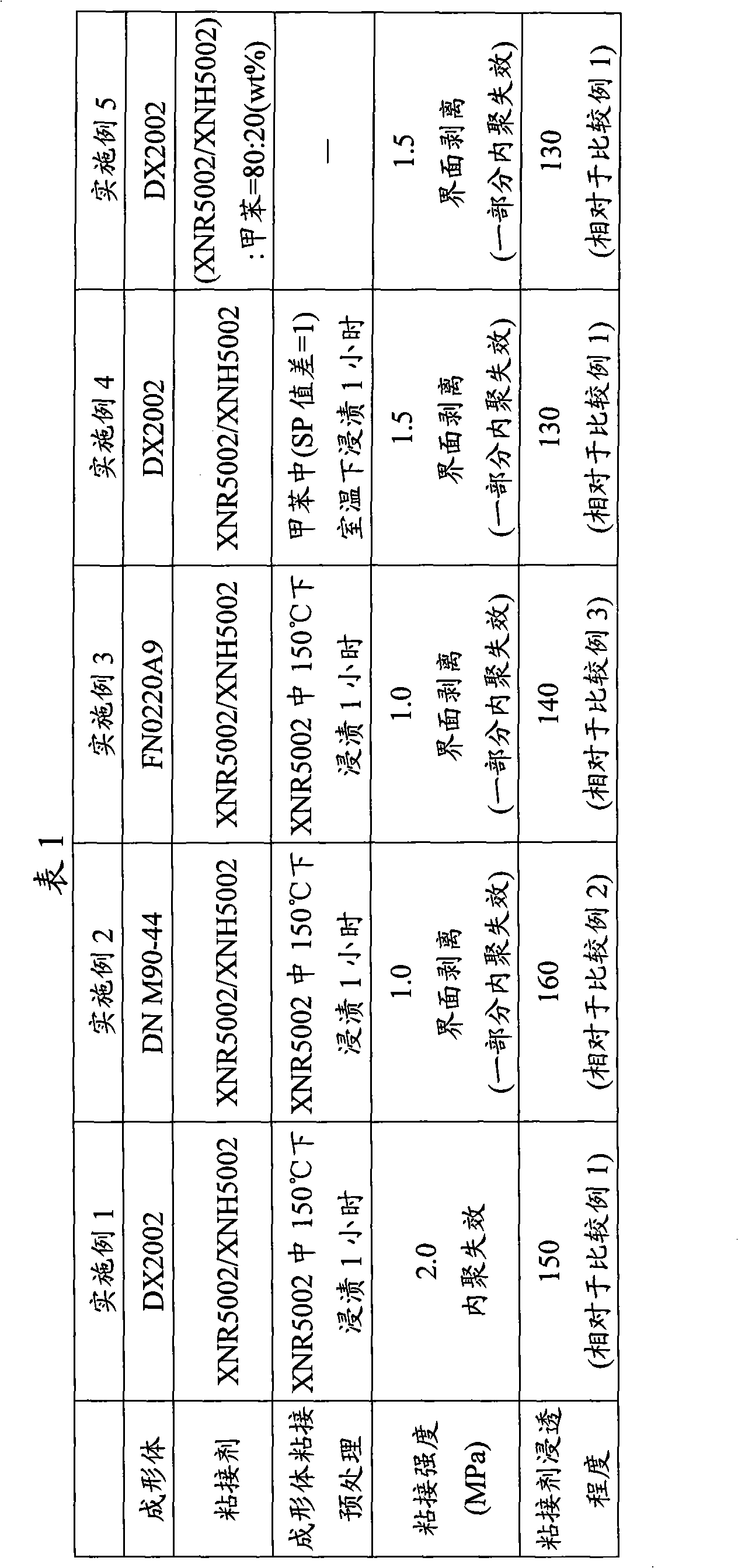

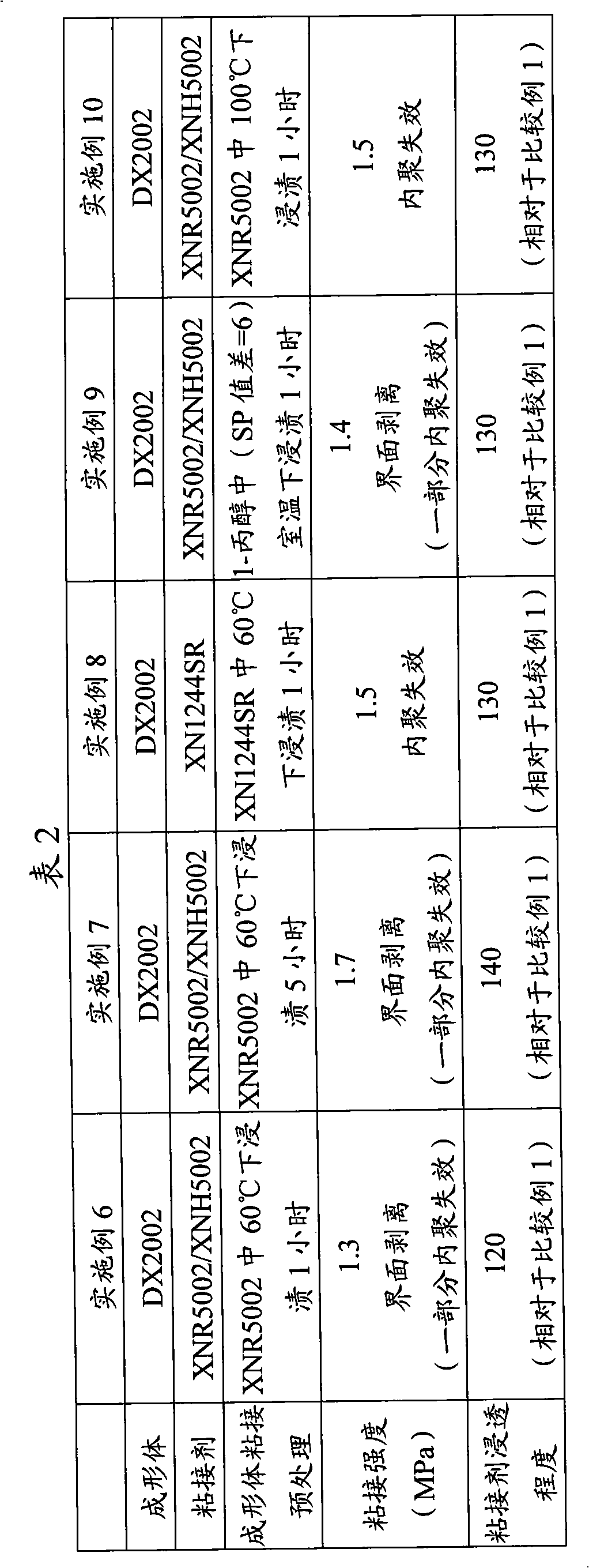

Embodiment 1

[0038] DX 2002 (manufactured by Polyplastics Co., Ltd., polybutylene terephthalate) was used as a molded body, and main agent XNR5002 / curing agent XNH5002 (manufactured by Nagase ChemteX Corporation) was used as an adhesive. As an adhesion pretreatment, the molded body was immersed in the main agent XNR5002, and immersed at 150°C for 1 hour. After the pretreatment, the bonding treatment is performed using a common bonding method, and curing is carried out under the curing conditions of 150° C. and 3 hours. After curing, a bond strength test was carried out after 24 hours.

Embodiment 2

[0040] Except for using DN M90-44 (Polyplastics Co., Ltd., polyacetal) as the molded body, the bonding pretreatment and bonding treatment were performed in the same manner as in Example 1, and bonding was carried out 24 hours after curing. Bonding strength test.

Embodiment 3

[0042] Except for using FN 0220A9 (Polyplastics Co., Ltd., polyphenylene sulfide) as the molded body, the same method as in Example 1 was used for adhesion pretreatment and adhesion treatment, and adhesion was carried out after 24 hours after curing. strength test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com