Production method of special-shaped superbright fully drawn yarn-low-elastic yarn

A technology of fully drawn yarn and production method, which is applied in the direction of drawing spinning, filament/thread forming, textile and paper making, etc. The problem of poor shape retention and other problems can achieve the effect of good shape, bright gloss and stable product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

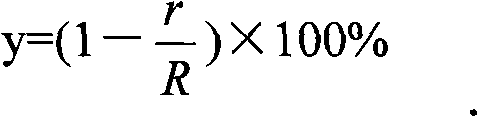

Embodiment 1

[0025] 50dtex / 36f special-shaped super-bright FDY-DTY polyester filament: DTY is made of super-bright special-shaped FDY after stretching, deformation and micro-network process. Among them, the oiling rate of FDY is 0.8%, the elongation at break is 30%, and the elongation variation coefficient CV% is 3.00%; the first hot box temperature of DTY is 185°C, the second hot box temperature is 175°C, and the stretch ratio is 1.01 , processed into DTY, the breaking strength is 3.50cN / dtex, the elongation at break is 30%, and the special-shaped cross-section is a trilobal shape, wherein the special-shaped degree y of FDY is 33%, and the special-shaped degree y of DTY is 31%. The maintenance of the special-shaped degree Up to 94%. This product not only has super bright luster, good moisture absorption performance, but also has a soft and plump feel when processed into fabrics.

Embodiment 2

[0027] 75dtex / 72f special-shaped super-bright FDY-DTY polyester filament: DTY is made of super-bright special-shaped FDY after stretching, deformation and micro-network process. Among them, the oiling rate of FDY is 1.0%, the elongation at break is 20%, and the elongation variation coefficient CV% is 3.00%; the temperature of the first hot box of DTY is 185°C, the temperature of the second hot box is 180°C, and the stretching ratio is 1.03 , processed into DTY, the breaking strength is 4.00cN / dtex, the elongation at break is 20%, and the special-shaped cross-section is trilobal, wherein the special-shaped degree y of FDY is 30%, and the special-shaped degree y of DTY is 28%. Up to 93%. This product not only has super bright luster, good moisture absorption performance, but also has a soft and plump feel when processed into fabrics.

Embodiment 3

[0029] 50dtex / 24f special-shaped super-bright FDY-DTY polyester filament: DTY is made of super-bright special-shaped FDY after stretching, deformation and micro-network process. Among them, the oiling rate of FDY is 0.6%, the elongation at break is 25%, and the elongation variation coefficient CV% is 3.00%. , processed into DTY, the breaking strength is 3.70cN / dtex, the elongation at break is 25%, and the special-shaped cross-section is trilobal. Among them, the special-shaped degree y of FDY is 32%, and the special-shaped degree y of DTY is 30%. The maintenance of special-shaped degree Up to 92.5%. This product not only has super bright luster, good moisture absorption performance, but also has a soft and plump feel when processed into fabrics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com