High abrasion-proof diamond composite cutter bit

A composite pick and diamond technology, applied in cutting machinery and other directions, can solve the problems of non-wear-resistance of pick shank, insignificant effect, damage and failure of picks, etc., so as to improve overall life, improve mining efficiency, and reduce mining costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

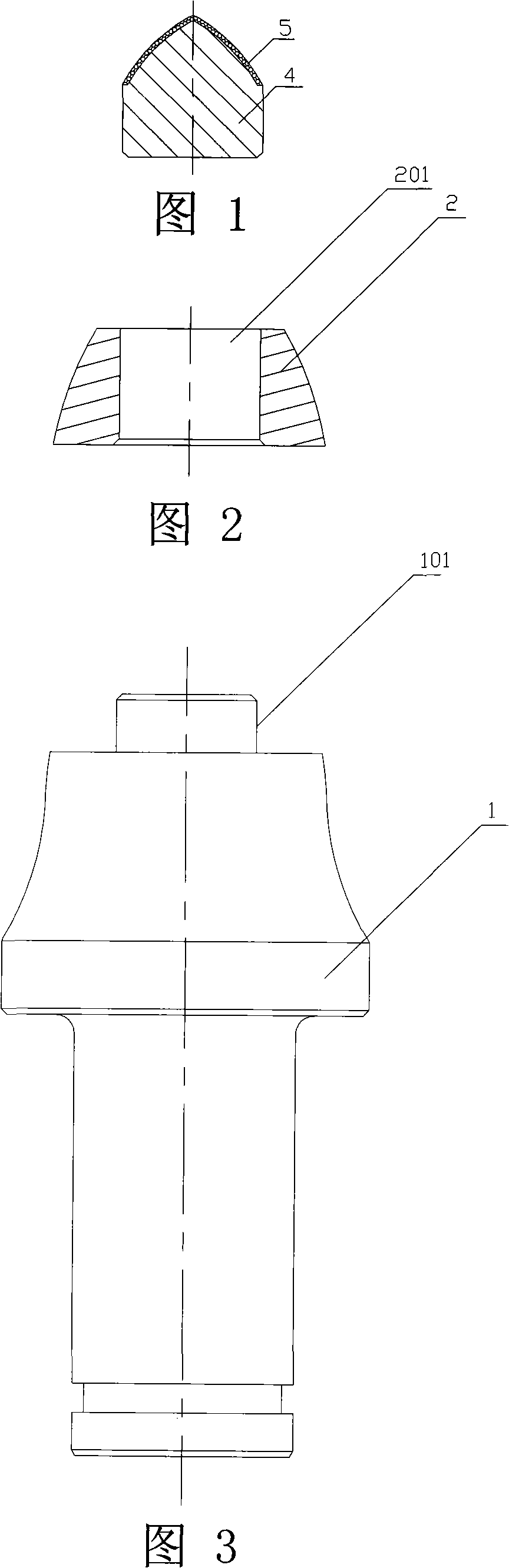

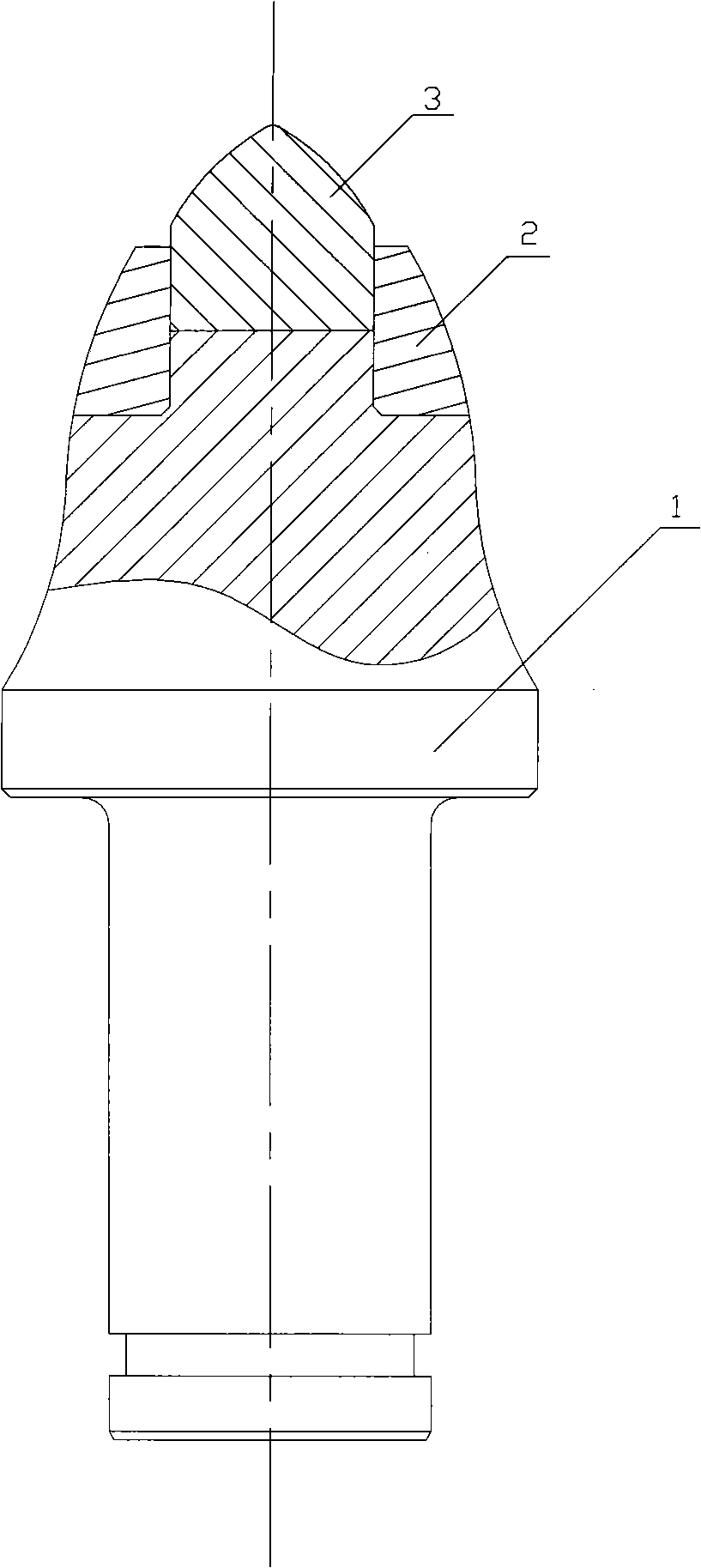

[0033] Embodiment 1: as shown in Figure 1, Figure 2, Figure 3, Figure 4 and Figure 5 Shown, a kind of high wear-resisting diamond composite pick of the present invention, it comprises pick shank 1, pick seat 2 and pick head 3, pick seat 2 is connected to an end of pick handle 1, pick head 3 It is fixed in the pick holder 2, and the said pick holder 2 is made of hard alloy material, and the hard alloy pick holder 2 has good wear resistance, which ensures the radial stability of this part during use. The connection between the pick head 1 and the pick holder 2 can be silver brazing, or copper brazing, or cold pressure interference press-in, or hot-press interference press-in. The connection between the pick holder 2 and the pick shank 1 can also be silver brazing, or copper brazing, or cold pressure interference press-in, or hot-press interference press-in. In this embodiment, the connecting end of the pick shank 1 and the pick holder 2 is provided with a connecting portion 1...

Embodiment 2

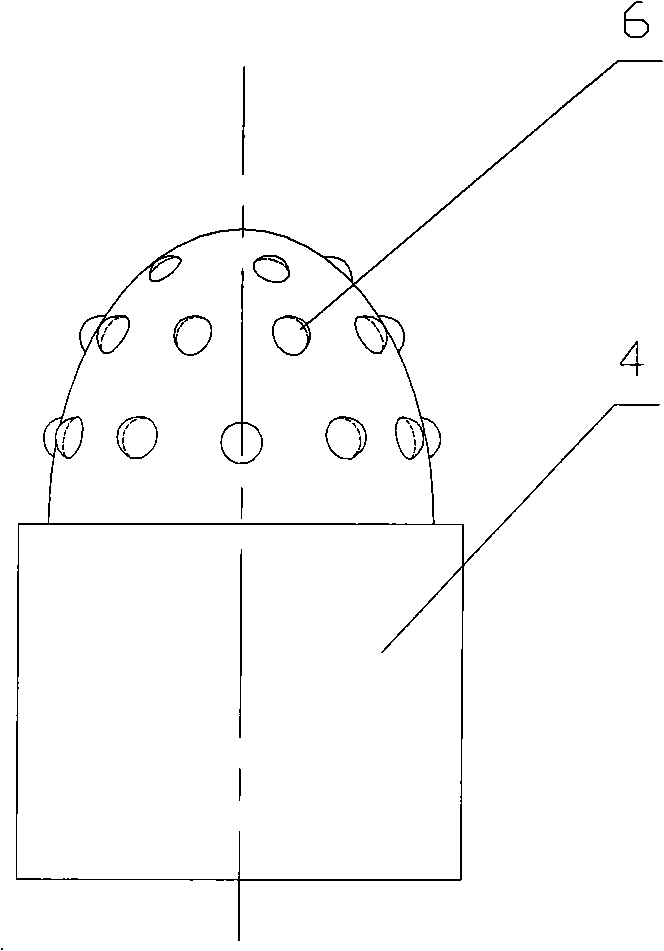

[0034] Embodiment 2: as shown in Figure 1, Figure 5 , Figure 6, Figure 7 and Figure 8 Shown, a kind of high wear-resisting diamond composite pick of the present invention, it comprises pick shank 1, pick seat 2 and pick head 3, pick seat 2 is connected to an end of pick handle 1, pick head 3 It is fixed in the pick holder 2, and the said pick holder 2 is made of hard alloy material, and the hard alloy pick holder 2 has good wear resistance, which ensures the radial stability of this part during use. The connection between the pick head 1 and the pick holder 2 can be silver brazing, or copper brazing, or cold pressure interference press-in, or hot-press interference press-in. The connection between the pick holder 2 and the pick shank 1 can also be silver brazing, or copper brazing, or cold pressure interference press-in, or hot-press interference press-in. In this embodiment, the connecting end of the pick handle 1 and the pick holder 2 is provided with a pick holder accom...

Embodiment 3

[0035] Embodiment 3: as shown in Fig. 1, Fig. 2, Fig. 3, Figure 4 and Figure 5Shown, a kind of high wear-resisting diamond composite pick of the present invention, it comprises pick shank 1, pick seat 2 and pick head 3, pick seat 2 is connected to an end of pick handle 1, pick head 3 It is fixed in the pick holder 2, and the said pick holder 2 is made of hard alloy material, and the hard alloy pick holder 2 has good wear resistance, which ensures the radial stability of this part during use. The connection between the pick head 1 and the pick holder 2 can be silver brazing, or copper brazing, or cold pressure interference press-in, or hot-press interference press-in. The connection between the pick holder 2 and the pick shank 1 can also be silver brazing, or copper brazing, or cold pressure interference press-in, or hot-press interference press-in. In this embodiment, the connecting end of the pick shank 1 and the pick holder 2 is provided with a connecting portion 101, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com