Developing device and developing method thereof

A developing device and developing solution technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of decreased chemical properties, difficulty in maintaining the electrical conductivity of the developing solution constantly, and increased electrical conductivity of the developing solution, etc. medicinal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

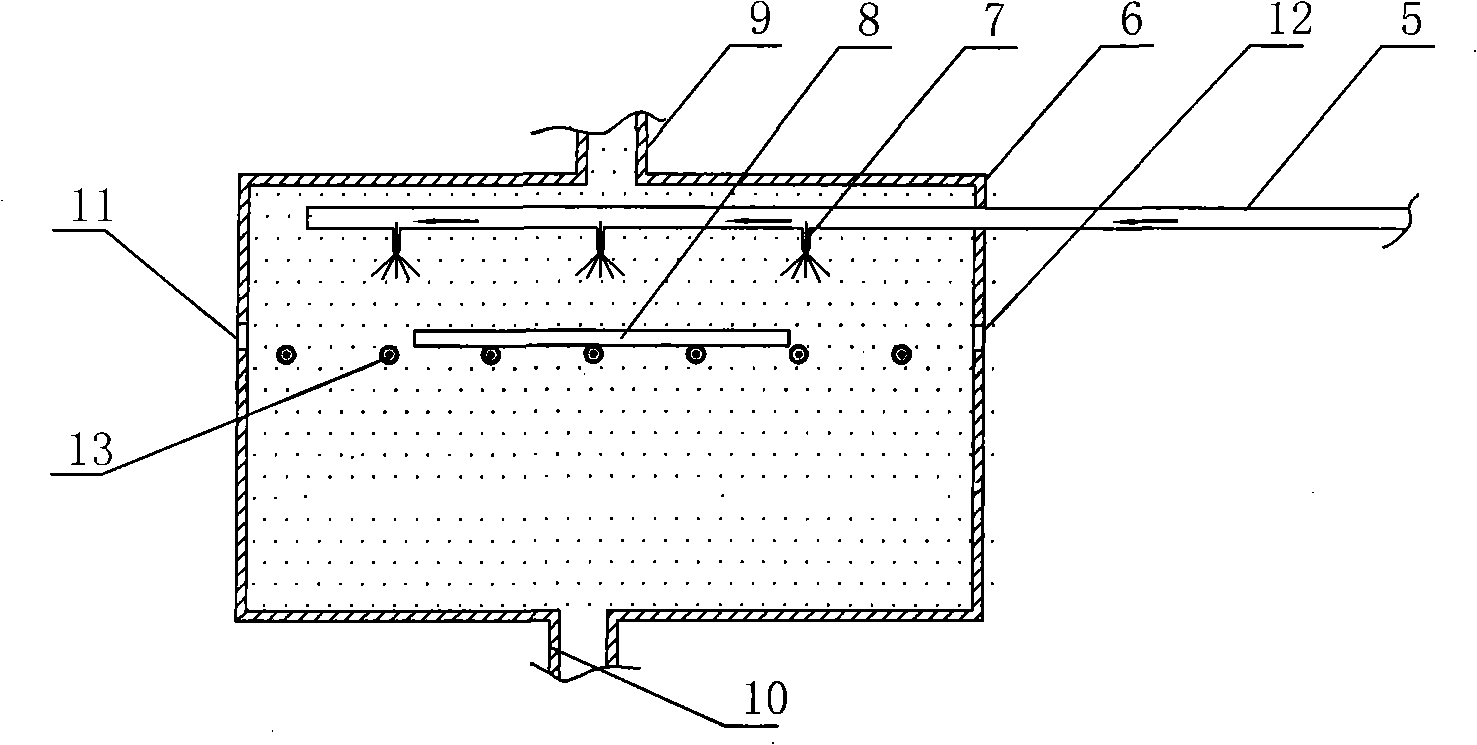

[0035] Embodiment 1 provides a device for preventing the developer solution from reacting with air and other gases during the assembly line production process. This embodiment increases N in the existing developing tank 2 source 1. The roller 13 transfers the substrate 8 from the substrate inlet 11 into the developing tank. Open the flow regulating device 3 to make the developing tank 6 full of N 2 . Turn on the control switch of the developer, and the developer is sprayed onto the substrate through the developer liquid supply pipeline 5 and the nozzle 7 . During the developer spraying process, the flow regulating device is kept open, and the flow control device is controlled according to the gas discharge from the exhaust port 9 . After the development is completed, the substrate is conveyed out of the development tank by rollers.

Embodiment 2

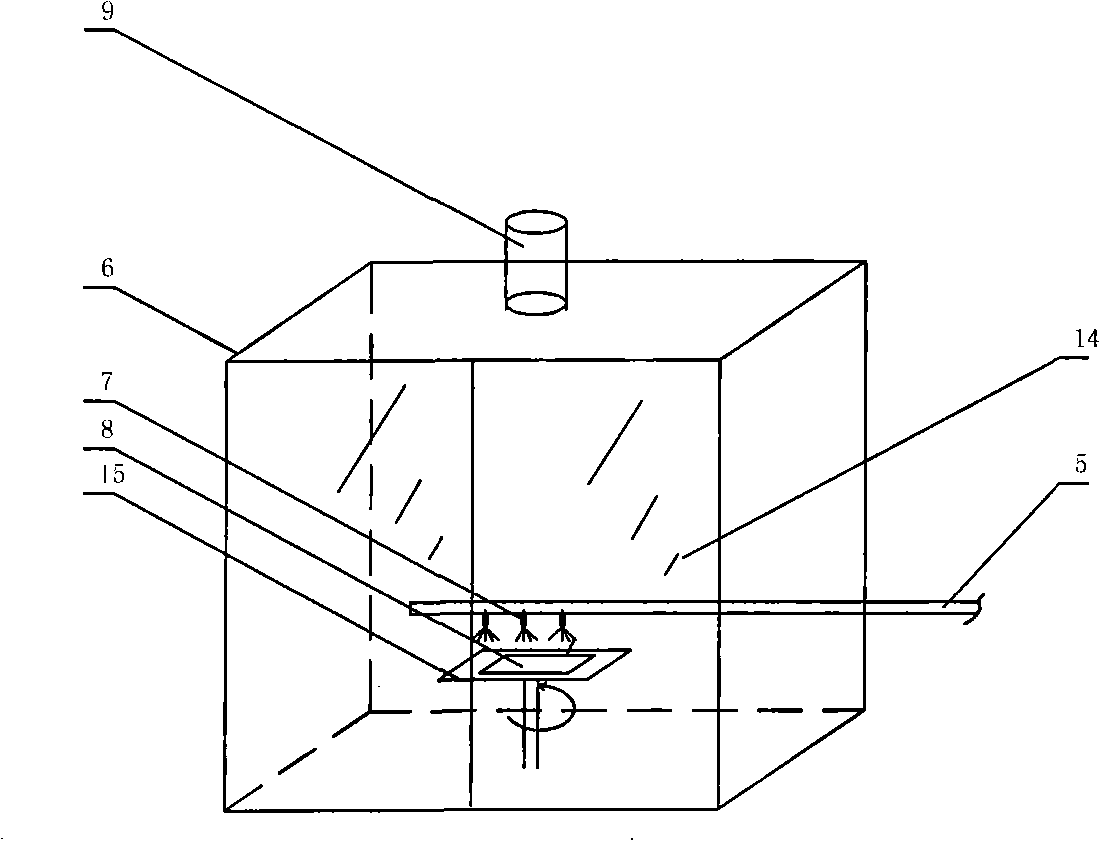

[0036] Embodiment 2 provides a device and method for preventing the developer solution from reacting with air and other gases during the small-batch experimental production process. In this embodiment, an auxiliary pipeline 2 is added in the existing developing tank, and the auxiliary pipeline extends from the outside of the tank to the inside of the tank. One end of the auxiliary pipeline located outside the tank is connected to N 2 Source 1, the bottom of the auxiliary pipeline in the tank is evenly distributed with multiple N 2 Spout 4. Open the door 14 of the developing tank, and put the substrate to be developed on the rotating platform 15 . open N 2 Source and flow regulating device 3, so that the developing tank 6 is filled with N 2 . The control switch for controlling the developing solution is turned on, and the developing solution is sprayed onto the substrate through the developing solution supply pipeline 5 and the nozzle 7 . During the developer spraying pro...

Embodiment 3

[0037] Embodiment 3 also provides a device and method for preventing the developer solution from reacting with air and other gases during the assembly line production process. In this embodiment, an auxiliary pipeline 2 is added in the existing developing tank, and the auxiliary pipeline extends from the outside of the tank to the inside of the tank. One end of the auxiliary pipeline located outside the tank is connected to N 2 Source 1, the bottom of the auxiliary pipeline in the tank is evenly distributed with multiple N 2 Spout 4. The roller 13 transfers the substrate 8 from the substrate inlet 11 into the developing tank. open N 2 Source and flow regulating device 3, so that the developing tank 6 is filled with N 2 . The control switch for controlling the developing solution is turned on, and the developing solution is sprayed onto the substrate through the developing solution supply pipeline 5 and the nozzle 7 . During the developer spraying process, the flow regula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com