A gravity separator, and a method for separating a mixture containing water, oil, and gas

A technology for gravity separators and mixtures, applied in separation methods, chemical instruments and methods, solid separation, etc., can solve the problems of complex separators, high maintenance, clogging capacity, etc., and achieve maintenance costs free, reliable design, and simple design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

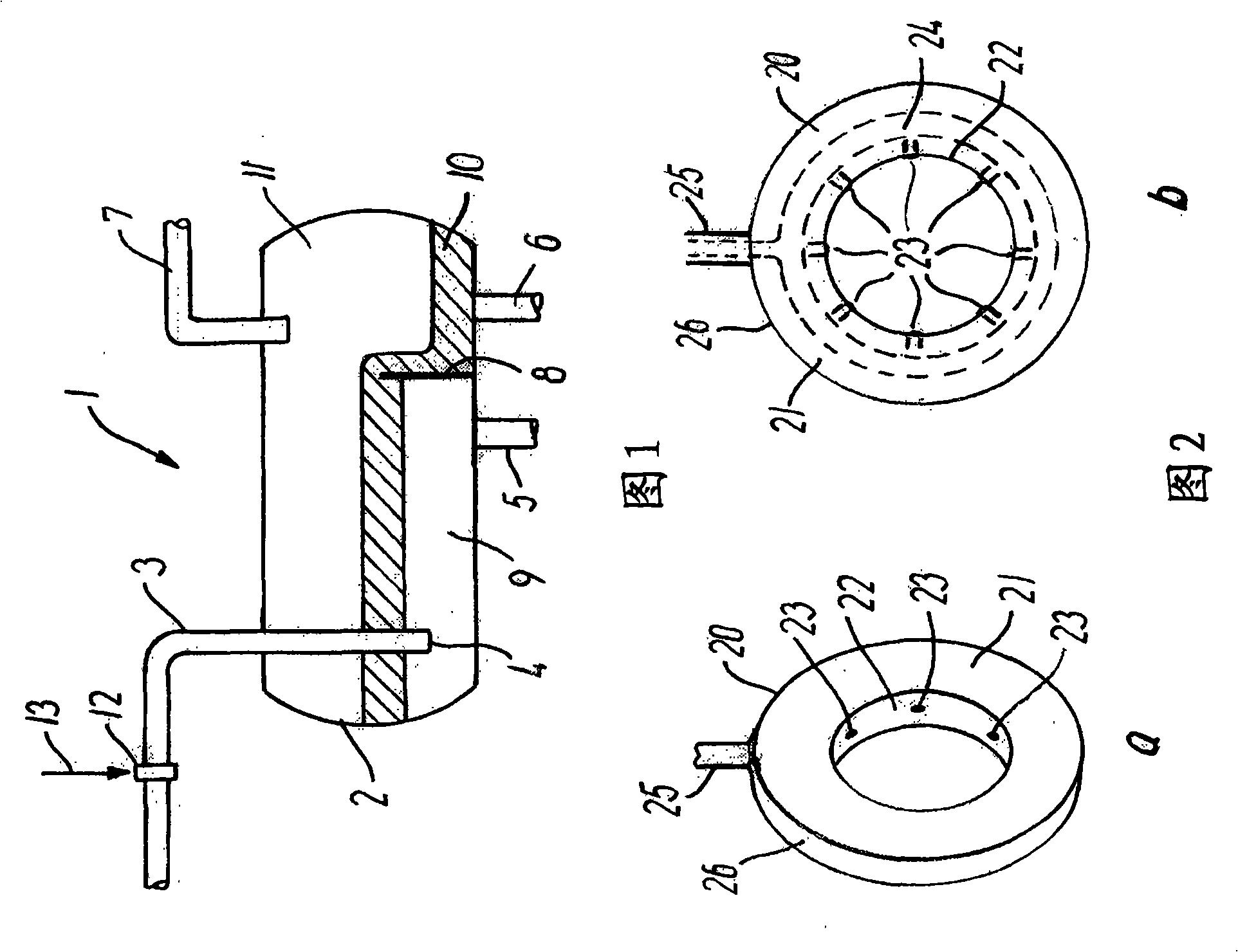

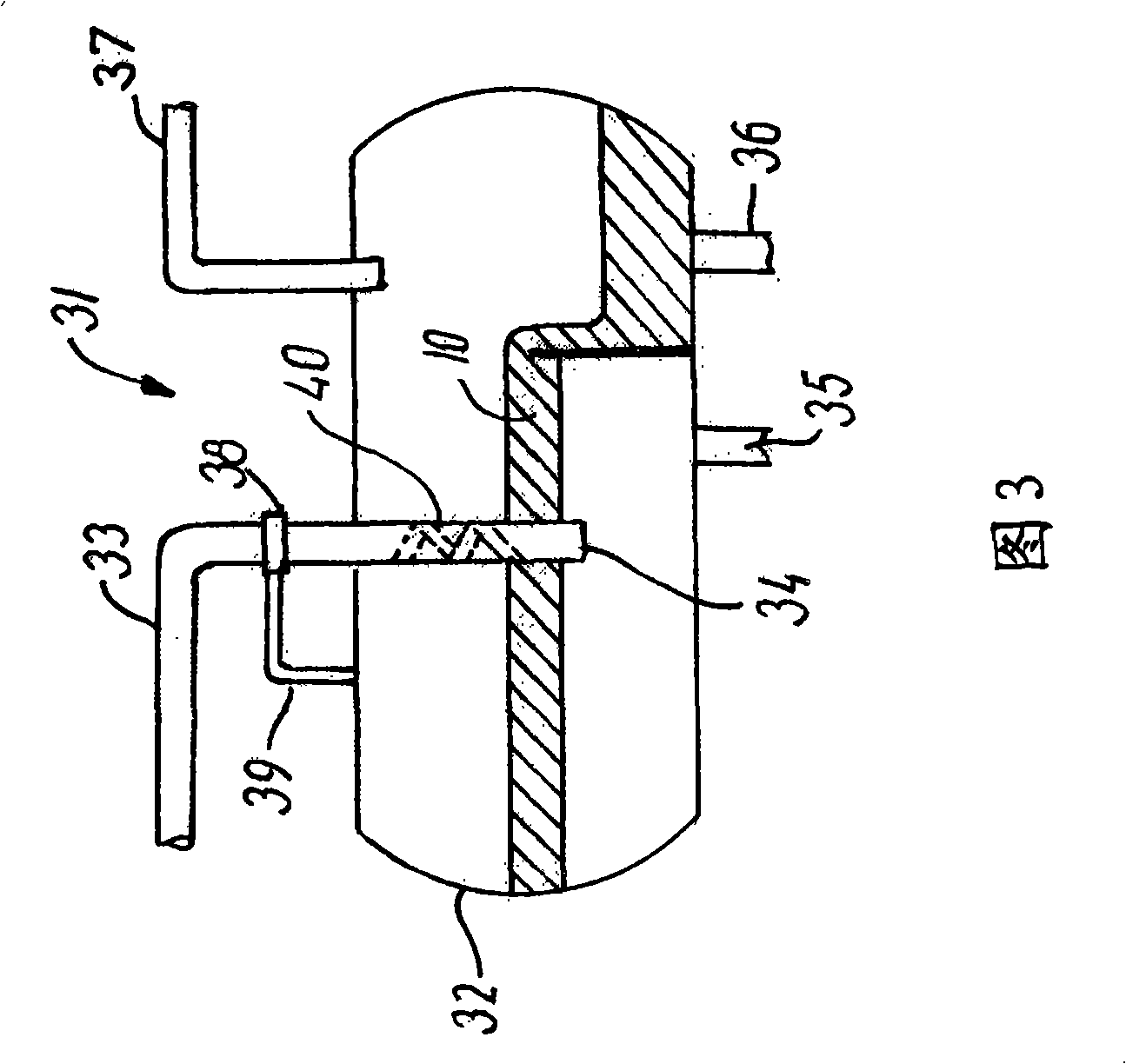

[0023] Referring to FIG. 1 , there is shown a gravity separator 1 having a vessel 2 with an inlet pipe 3 having a vessel inlet 4 inside the vessel 2 . The inflow of the fluid mixture through the inlet 4 spreads itself freely into the container where gravity acts on the ingredients in the mixture. The container 2 is also equipped with a water outlet 5 , an oil outlet 6 and a gas outlet 7 . Inside the vessel 2 there is a weir 8 which serves to separate the water phase 9 from the oil phase 10 . The gas phase 11 is collected at a position in the space above the water phase 9 and the oil phase 10 .

[0024] In the introduction pipe 3 of the container 2 there are installed injection means 12 for injecting gas in the form of a nozzle arrangement. A gaseous medium is fed to the nozzle arrangement via line 13 . In this way, a gaseous medium is sprayed into the mixture in the introduction pipe 3 before the mixture containing water, oil and gas enters the container 2 via the container...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com