Center pillar fine-adjustment mechanism of movable no-slewing meneuver

A fine-tuning mechanism and manipulator technology, which is applied to metal processing machinery parts, large fixed members, auxiliary devices, etc., can solve the problems of consistency, inability to weld, high precision, etc., achieve accurate welding, simple structure, and reduce installation requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

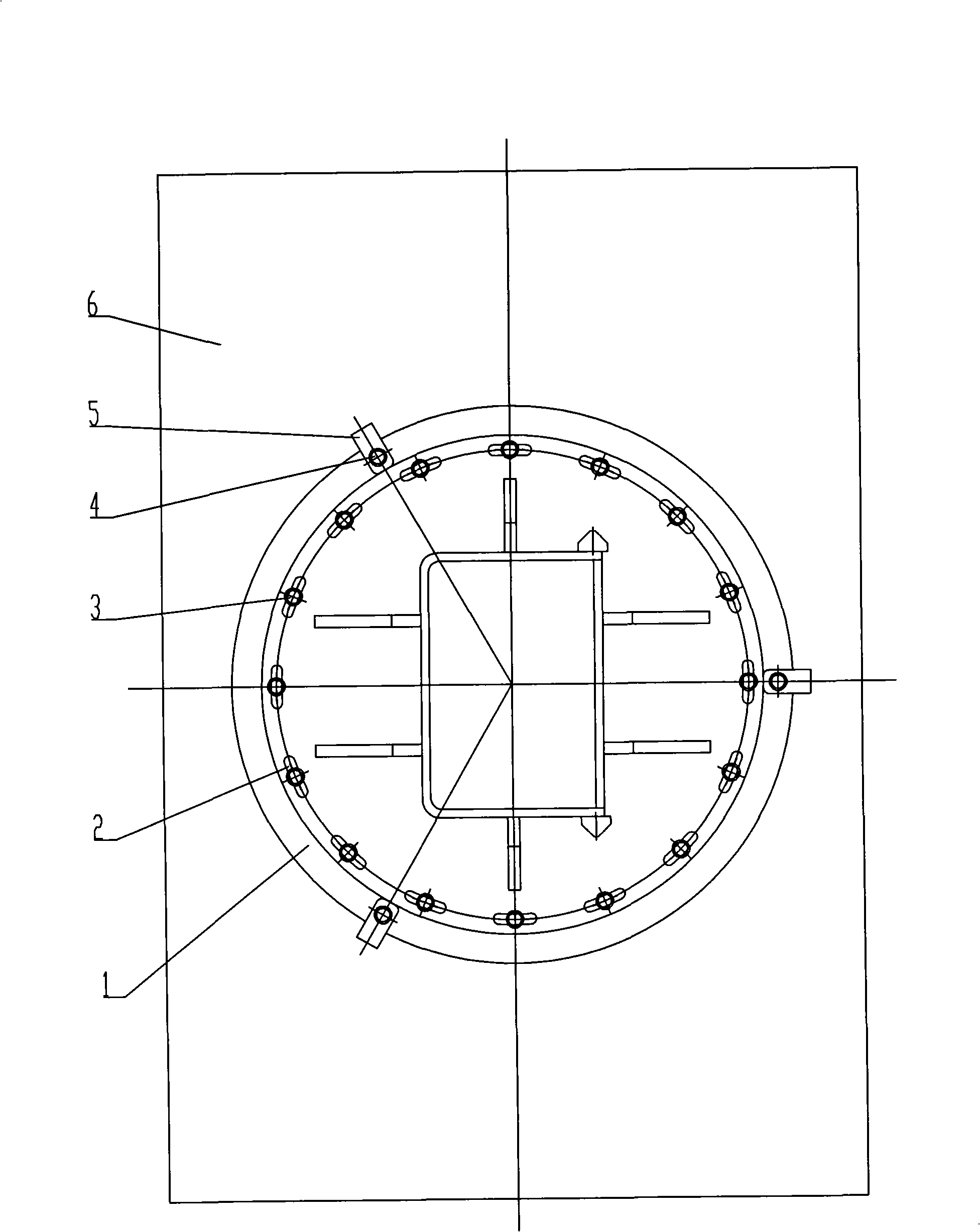

[0009] Such as figure 1 As shown, it includes: column bottom plate 1, U-shaped slot hole 2, bolt 3, bolt 4, adjustment block 5, trolley 6, etc.

[0010] In the present invention, a group of U-shaped slots 2 are arranged on the bottom plate 1 of the column, and the U-shaped slots 2 are evenly distributed; three adjustment blocks 5 are installed on the bottom plate 1 of the column through bolts 4, and then the bolts 3 are passed through the U-shaped slots. 2 Make the column bottom plate 1 stably installed on the trolley 6.

[0011] When installing the column bottom plate 1, do not tighten the bolt 3 first, adjust the installation angle of the column bottom plate 1 according to the installation situation of the track of the mobile roller frame on site, and hit the adjustment block 5 with a hand hammer during the adjustment process, when the column bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com