U-shaped anchorage cable

A U-shaped, anchor cable technology, which is applied in the direction of installation of anchor rods, sheet pile walls, building components, etc., can solve the problems of inconvenient replacement of anchor cables and inability to guarantee long-term anchorage, so as to achieve dispersed concentrated stress and anchor cable anchorage Reliable, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

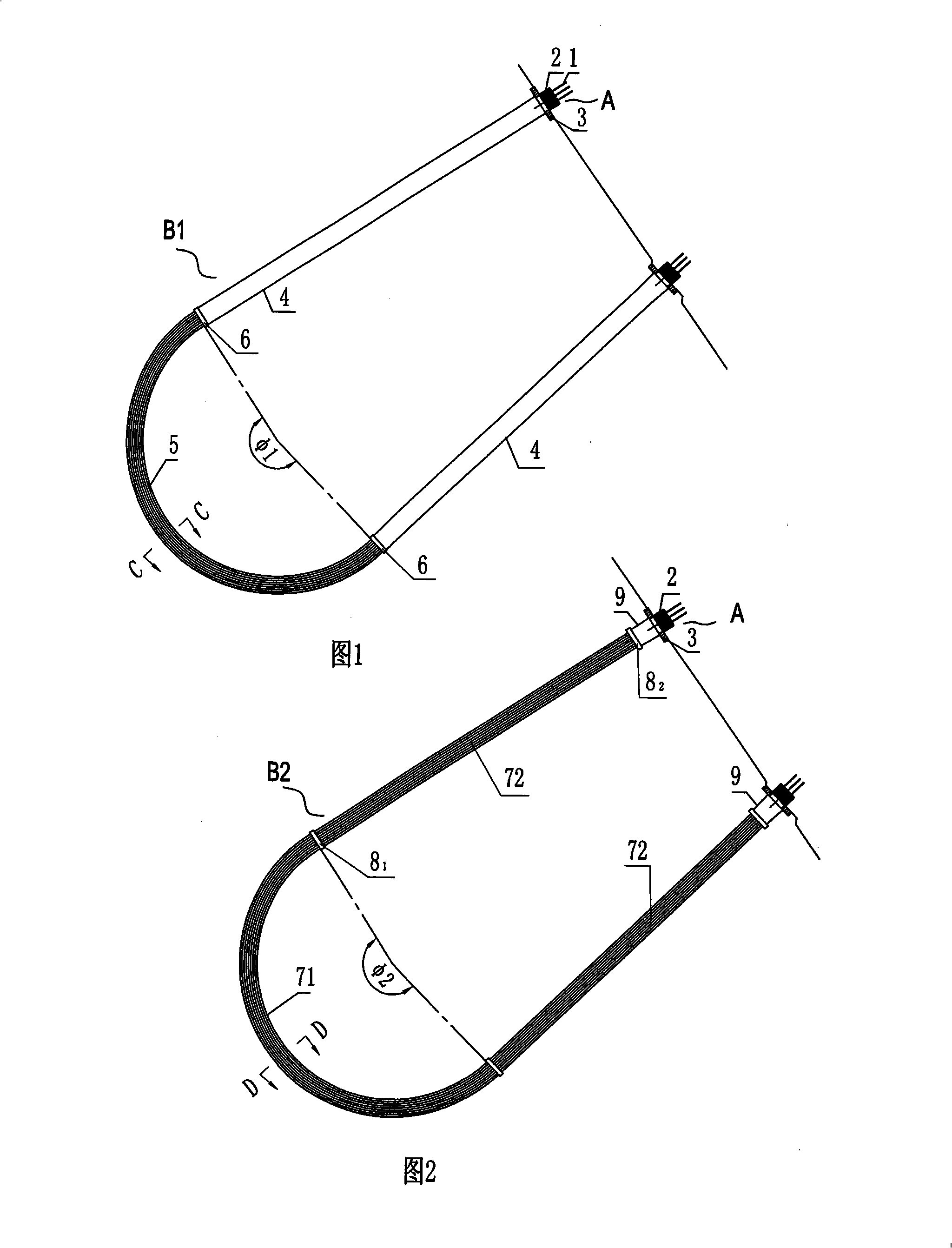

[0028] A U-shaped anchor cable whose U-shaped pipe seat is arc-shaped, as shown in Figure 1, the anchor cable includes an anchor cable body B1 and an outer anchor head A composed of an anchor 2 and an anchor pad 3. There are two outer anchor heads, and there is a long steel pipe 4 under the anchor backing plate 3 of the two outer anchor heads respectively, and the U-shaped pipe seat that the anchor cable body B1 passes through is an arc-shaped pipe composed only of arc-shaped segments. The wire splitting pipe seat 5, the central angle φ1 of the arc section is 190°, the two ends of the arc section are equipped with connecting plates 6 perpendicular to the axis of the pipe seat, and the lower ends of the two long steel pipes 4 are connected with the arc-shaped wire splitting pipe seat respectively. The connecting plates 6 at the two ends of the 5 are welded or flanged, and the anchor cable steel strands of each single cable body connected to the two outer anchor heads pass throug...

Embodiment 2

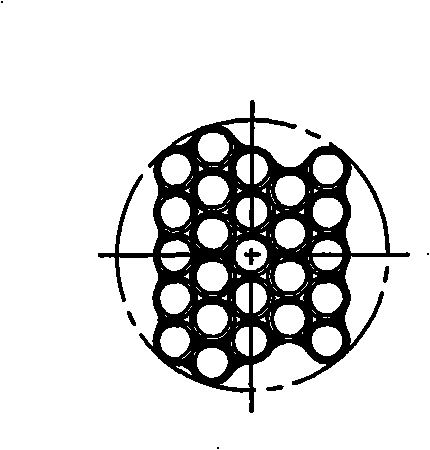

[0031] A U-shaped anchor cable whose straight section of the U-shaped pipe seat is extended to the orifice. As shown in Figure 2, the anchor cable includes an anchor cable body B2 and an outer anchor head A composed of an anchor 2 and an anchor plate 3. There are two outer anchor heads, and there is a section of short steel pipe 9 under the anchor backing plate 3 of the two outer anchor heads respectively. The lengthened U-shaped wire-separating pipe seat composed of straight section 72, the central angle φ2 of the arc section is 190°, the length of the straight section is 30000mm, and the connecting plate 8 perpendicular to the axis of the pipe seat is installed on the straight section 72 at both ends of the U-shaped pipe seat 1 ,8 2 , there is a short steel pipe 9 under the anchor backing plates of the two outer anchor heads respectively, and the arc section 71 and the straight section 72 of the U-shaped pipe seat pass through the connecting plate 8 1 Connection, the straig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com