High pressure dust gas sampling and decompression method and apparatus

A technology of gas sampling and decompression device, which is applied in the direction of sampling device, gas/liquid distribution and storage, pipeline system, etc. It can solve the problems affecting the accuracy and authenticity of the detection structure, particle loss, high dust concentration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

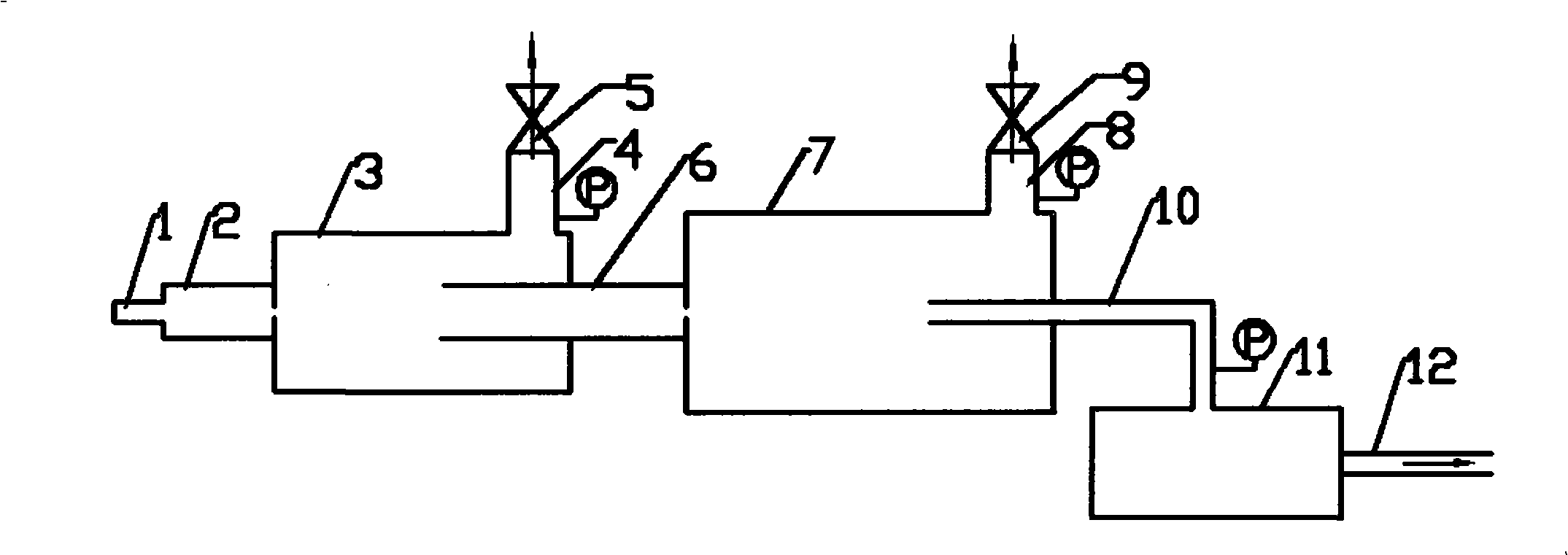

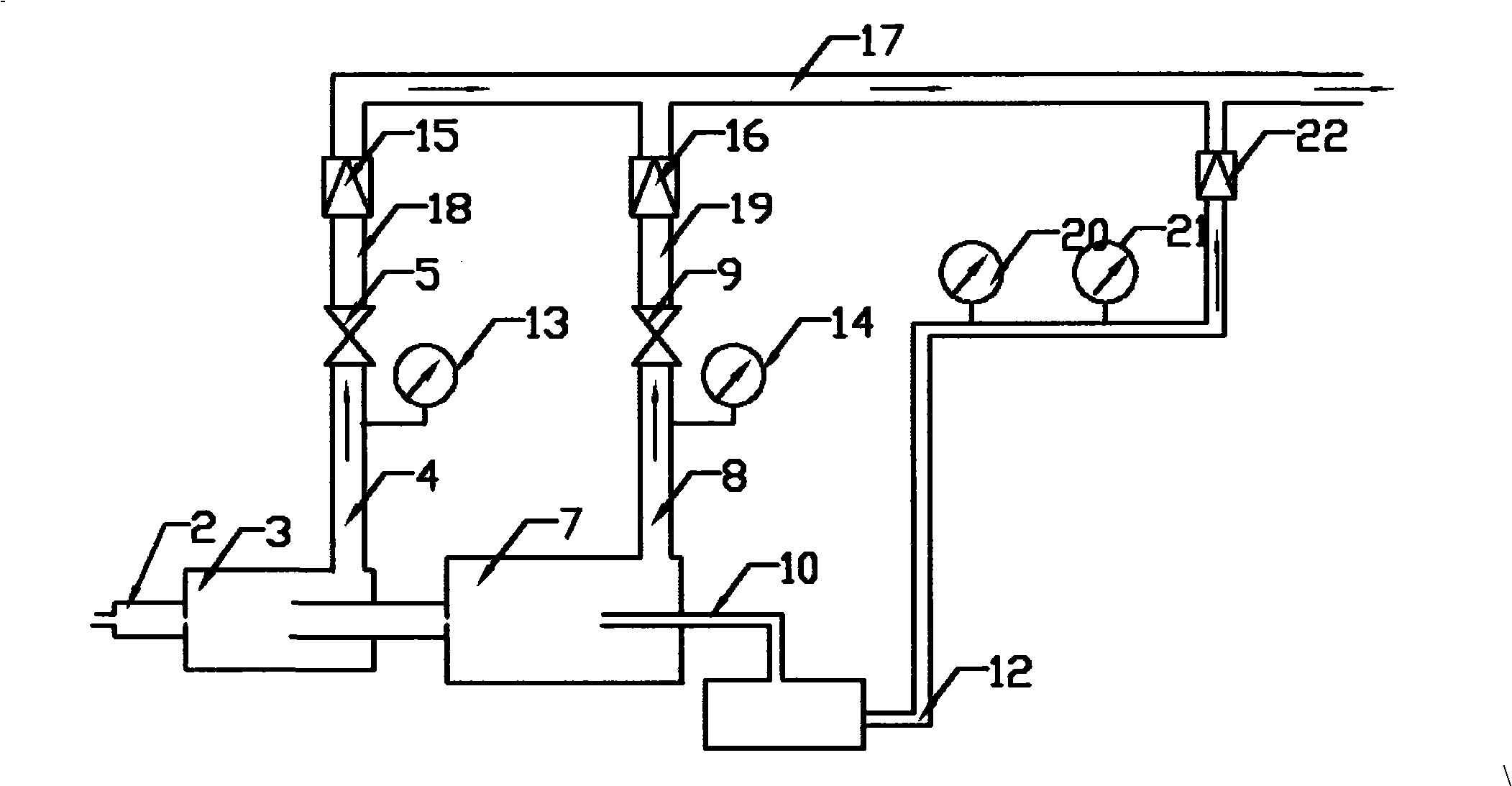

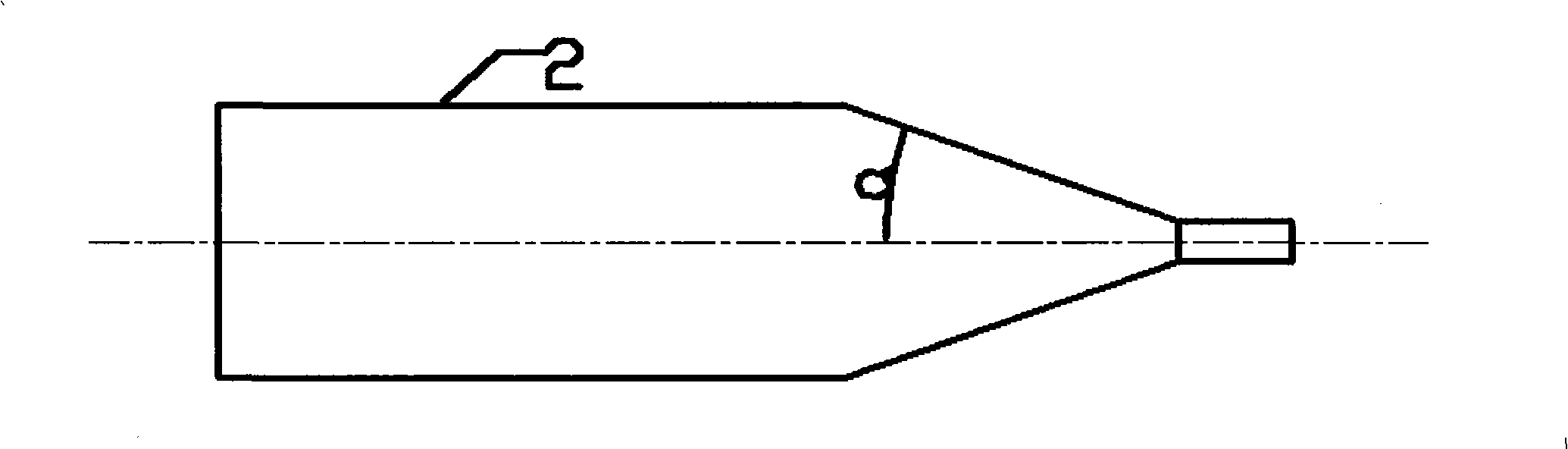

[0050] Embodiment. The specific embodiment of the present invention is described with this example and the present invention is described further. Its composition is as figure 1 - Figure 3. It consists of a primary sampling tube 1, a deceleration sampling tube 2, a primary expansion chamber 3, a primary discharge tube 4, a primary sample guide tube 6, a secondary expansion chamber 7, a secondary discharge tube 8 and a secondary sampling tube 10. . The front end of the primary expansion chamber 3 (with the deceleration sampling pipe 2 as the front) is connected to the deceleration sampling pipe 2, and a discharge port with a certain diameter is opened at the rear to connect with the primary discharge pipe 4 for discharging excess gas. The rear end of the primary expansion chamber 3 is connected to the primary sample guide tube 6 , and the primary sample guide tube 6 is inserted into the primary expansion chamber 3 to a certain depth. The front end of the secondary expansion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com