Lateral bipolar transistor and method of production

A bipolar transistor, horizontal technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as increasing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

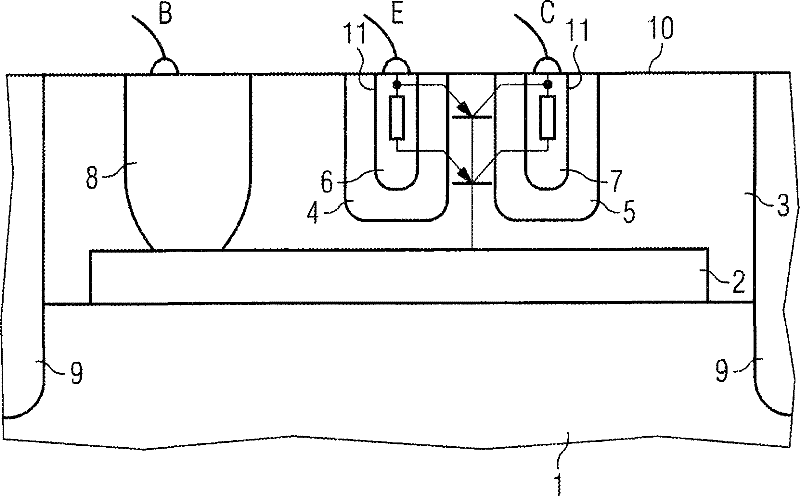

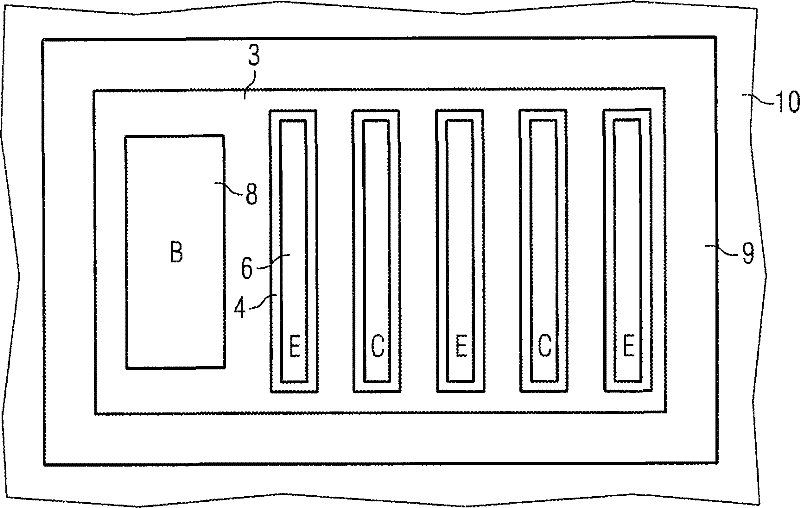

[0013] figure 1 A cross-section of an embodiment of a lateral bipolar transistor is shown. The transistor structure is located at the surface 10 of the semiconductor body 1 . The buried layer 2 of the first conductivity type can be arranged in a doped well 3 which is also of the first conductivity type but has a lower doping compared to the buried layer 2 . Separate doped regions 4 , 5 of a second conductivity type opposite to the first conductivity type are arranged in the well 3 . The conductive material 6, 7 is arranged in the trench 11 in contact with the doped regions 4, 5, so that one doped region 4 with the corresponding conductive material 6 forms an emitter, and the other doped region 5 with the corresponding conductive material 7 Forms the collector of the lateral bipolar transistor. Between the doped regions 4, 5 there is a doping material of the well 3 of opposite conductivity type. Therefore, there is a pn junction between the doped region and the well.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com