Method and device for picking medlar from medlar tree

A technology of wolfberry and branches, which is applied in the fields of picking machines, agricultural machinery and implements, applications, etc., can solve the problems of no mechanical device for picking wolfberry fruit, difficulty in making machinery and equipment, and high labor costs, saving manpower, compact structure, and high labor cost. Inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

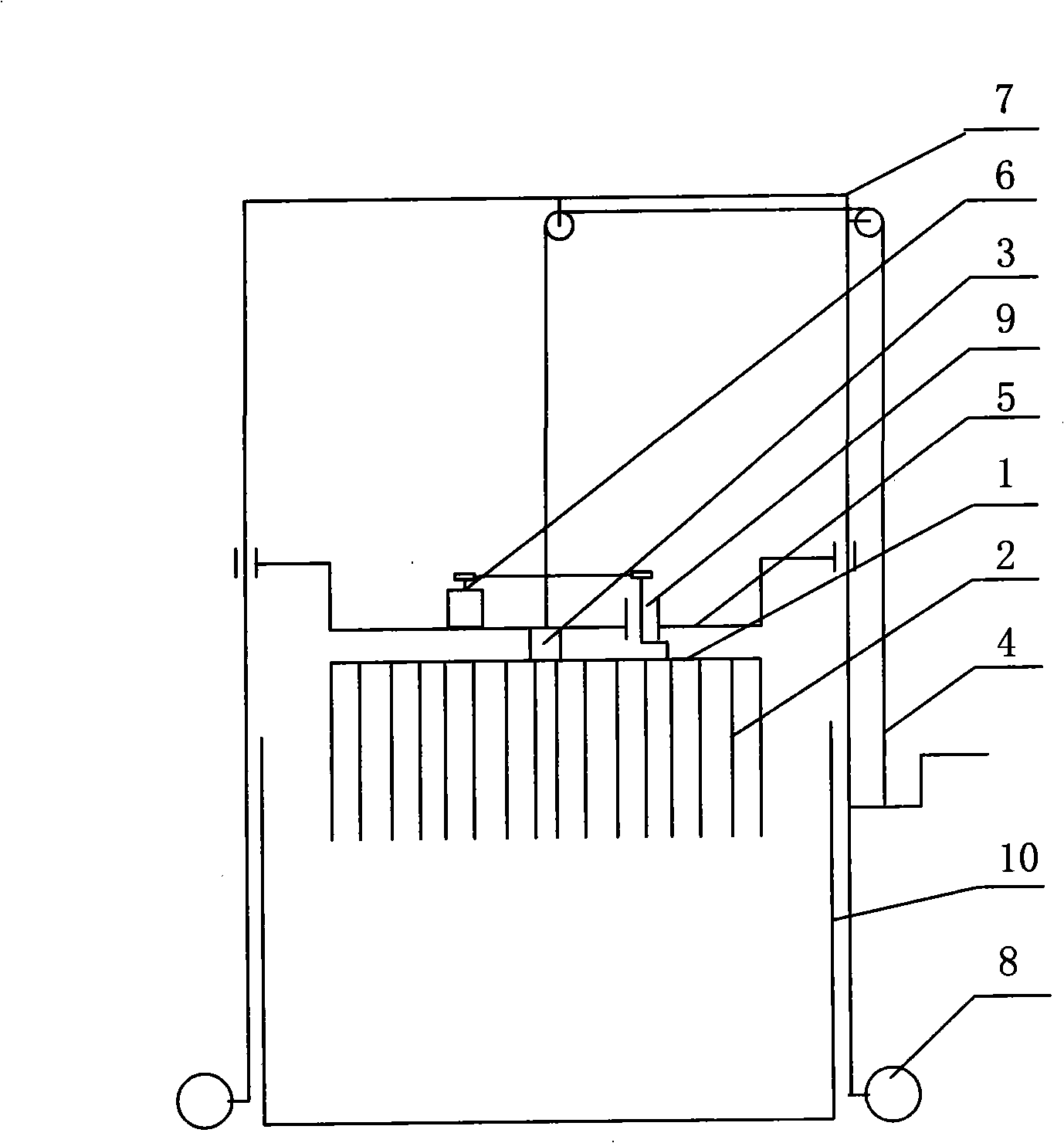

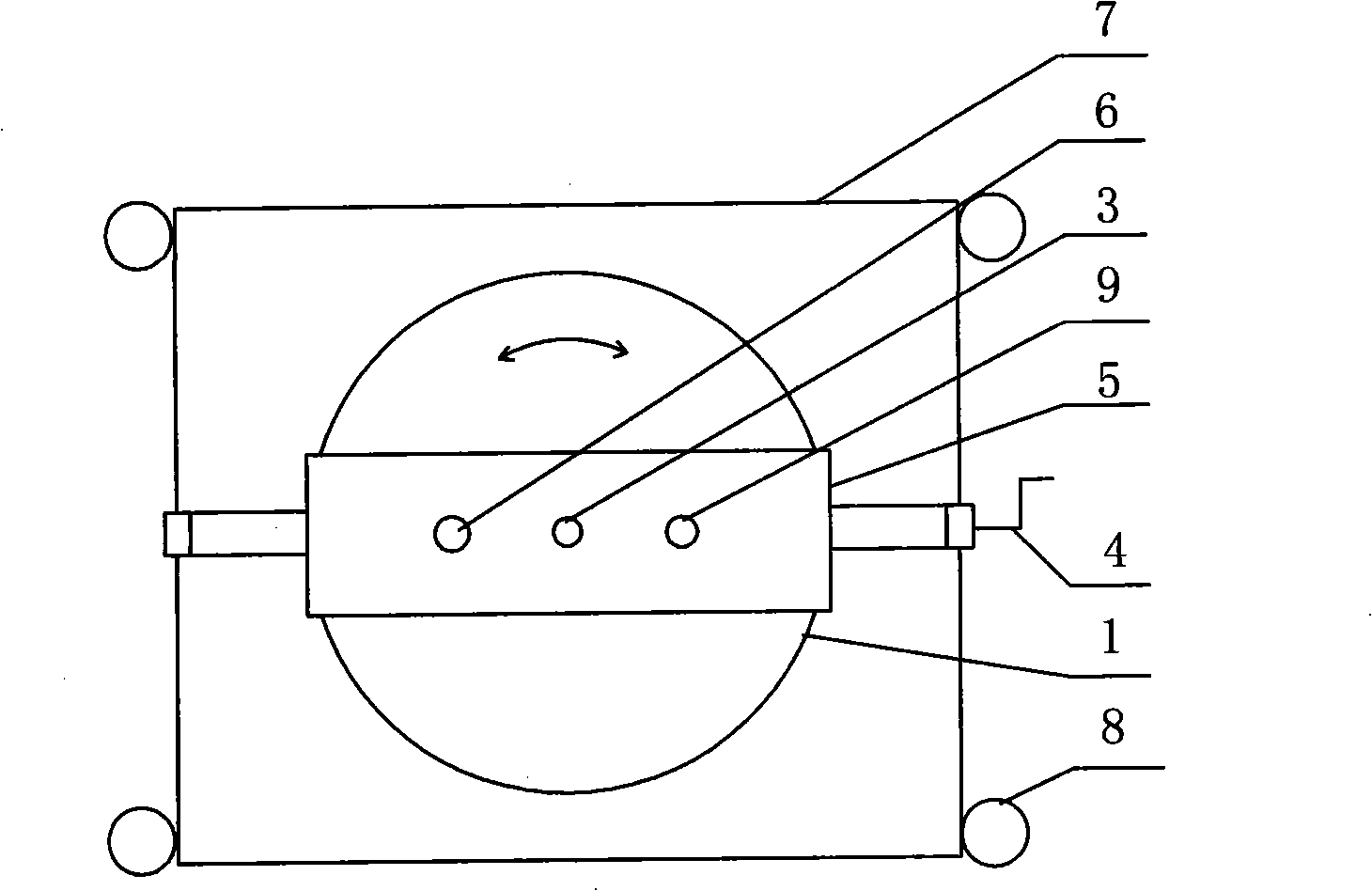

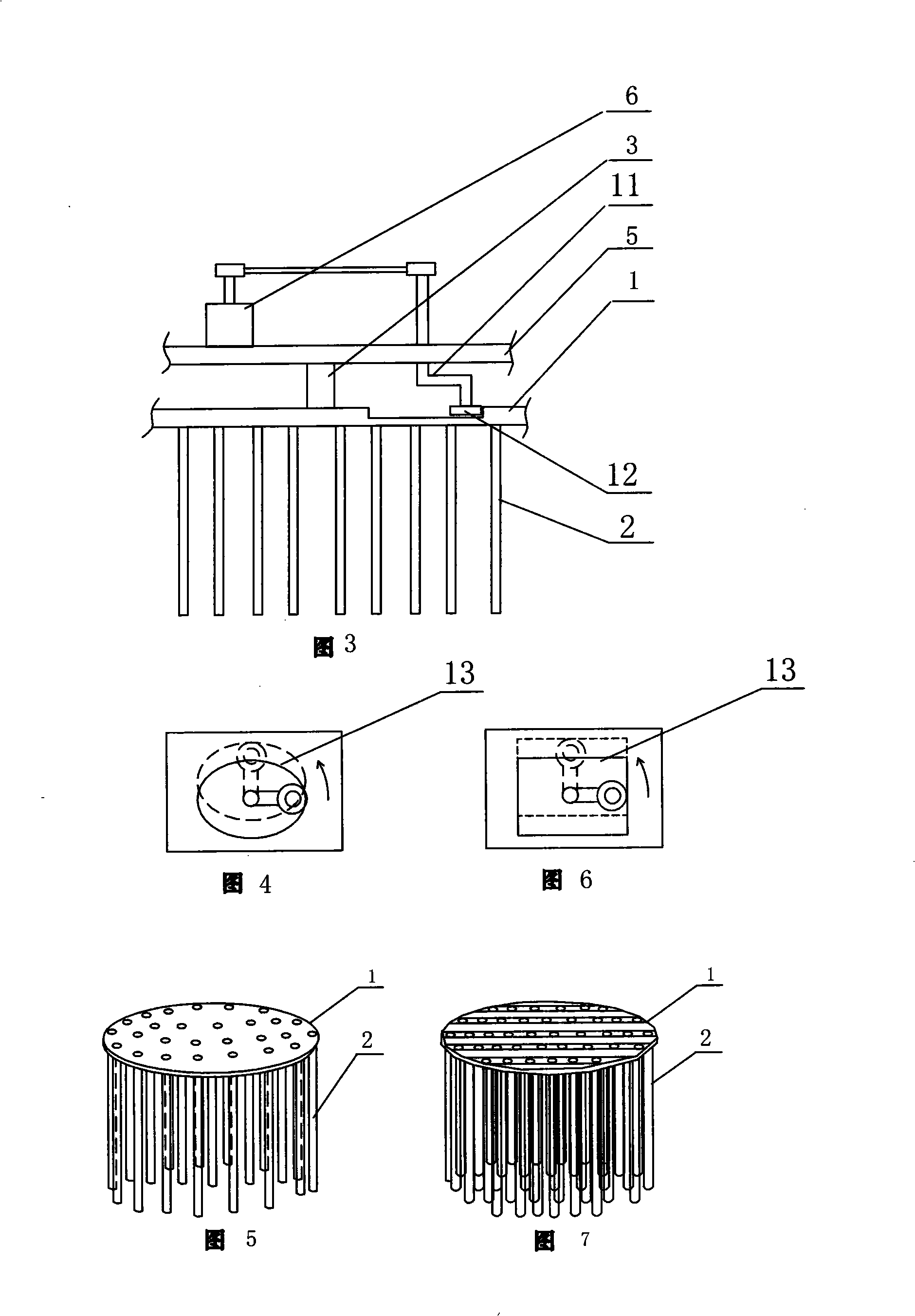

[0021] As shown in Figure 5, the vibrating plate 1 is vertically provided with a plurality of parallel vibrating rods 2, and the vibrating rods 2 are evenly arranged. Quantity, it is advisable to cover the crown of the tree and can be easily inserted into the crown of the tree. like figure 1 , 2 As shown in the picking device, the center of the vibrating plate 1 is provided with a rotary shaft 3, and the vibrating plate 1 is movably connected to the lifting frame 5 through the rotary shaft 3. The side is provided with the pulley connection mechanism 4 that can make the lifting frame 5 and the vibrating plate 1 and the vibrating rod 2 on it rise and fall up and down connected with the lifting frame 5, and jointly constitutes a lifting mechanism. Bracing frame 7 one side establishes hand rocker, shakes hand rocker, drives the wire rope on the pulley to pull up or puts down lifting frame 5, locates hand rocking bar or lifting frame 5 by positioning pin. Steering wheels 8 are s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com