Movable washing sterilizer

A mobile and decontamination technology, which is applied in the direction of valve devices, engine components, cleaning methods and appliances, etc., can solve the problem of inconvenient operation of continuous supply of water decontaminants, the inconvenient operation of continuous supply of water decontamination agents, etc. Solve problems such as single release mode, achieve the effect of protection safety, convenient operation and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

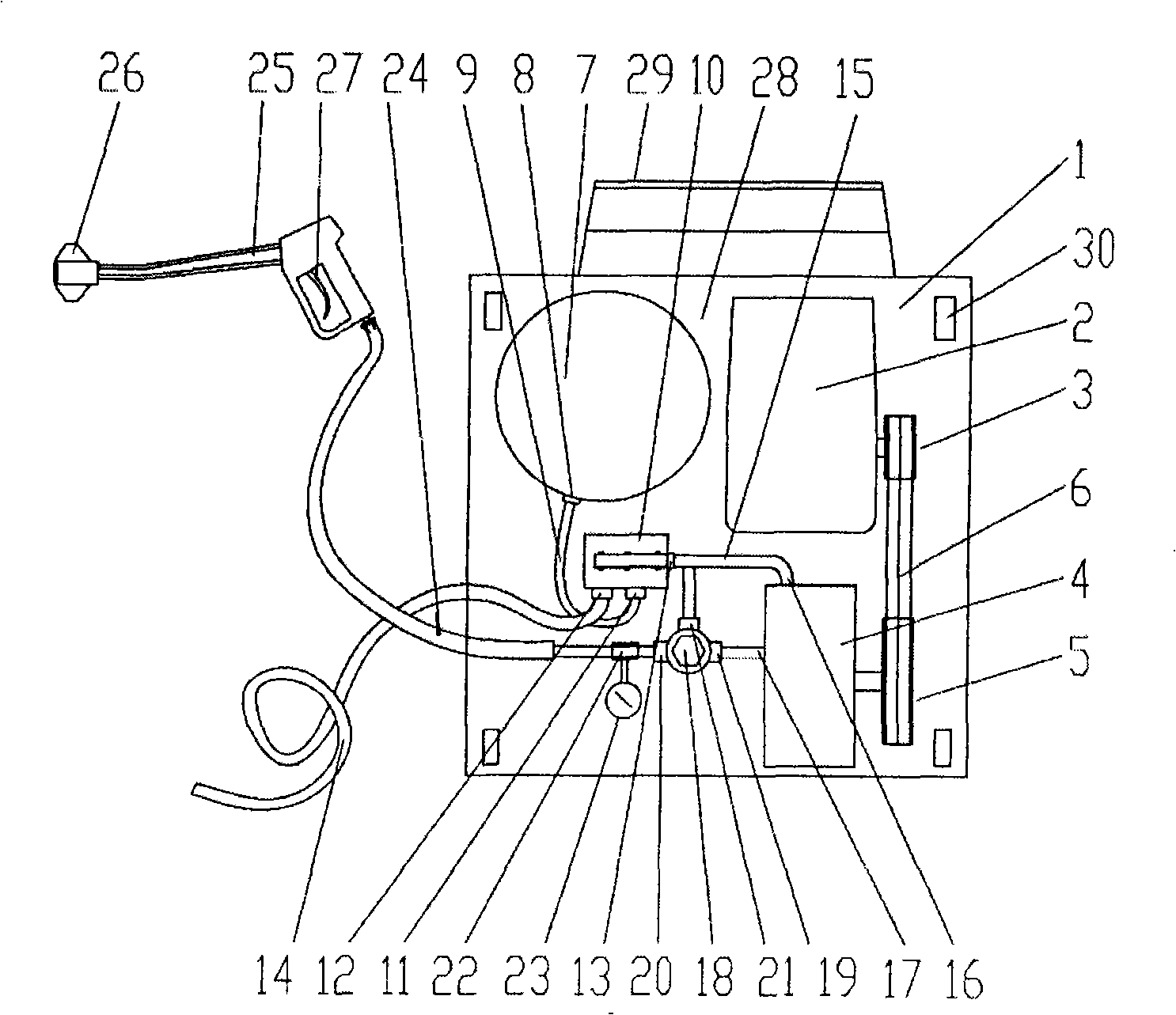

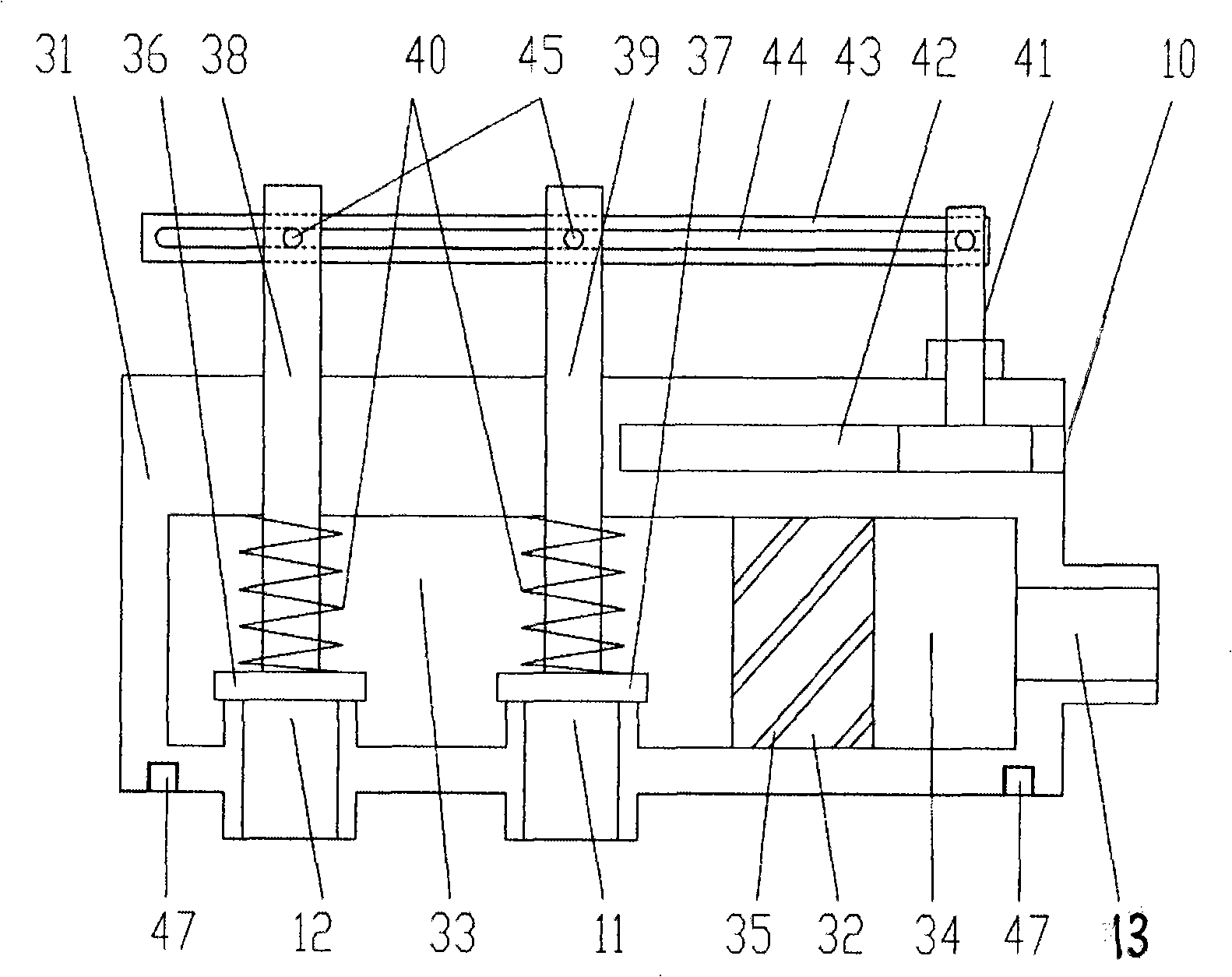

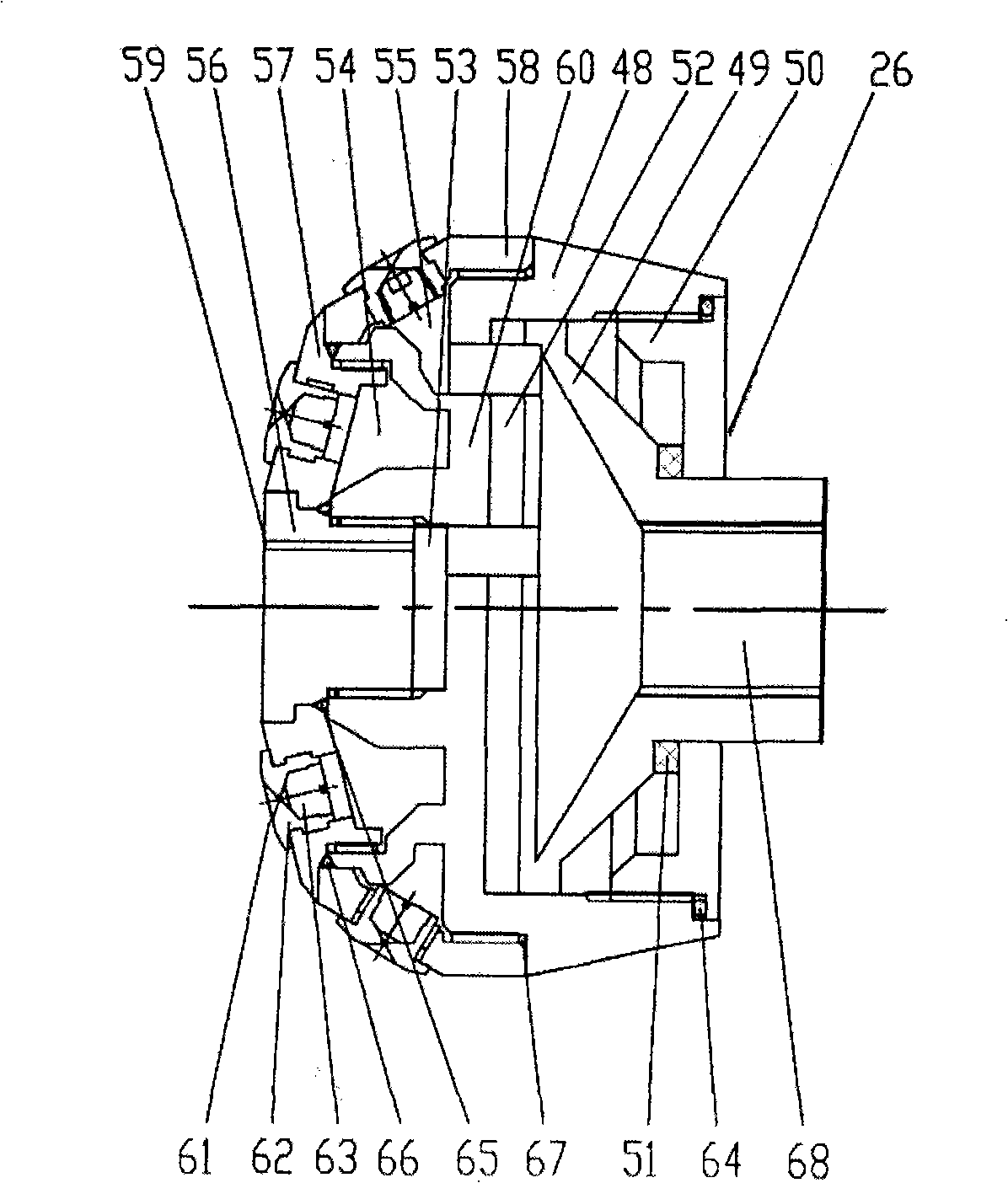

[0018] figure 1 A schematic top view of the structure of the mobile decontamination device of this embodiment is given. The power in the present embodiment adopts gasoline engine 2, also can adopt other power devices such as electric motor, diesel engine according to needs, and it and high-pressure pump 4 are all fixedly installed on the frame 1 with bolt; V is housed on the output shaft of gasoline engine 2 The pulley 3 and the power input shaft of the high-pressure pump 4 are equipped with a V-belt pulley 5, and the gasoline engine 2 and the high-pressure pump 4 are driven by a V-belt 6. The decontaminant storage tank 7 is fixedly installed on the frame 1, and the decontaminant storage tank outlet 8 located at the bottom of the decontaminant storage tank 7 is connected to the right inlet 11 of the proportional mixing valve through the decontaminant storage tank outlet pipe 9. The left inlet 12 of the mixing valve is connected with a water pipe 14, and the mixed liquid outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com