Manual plate cold-bending forming machine

A technology of cold bending forming machine and manual plate, which is applied in the field of manual plate cold forming machine, and can solve the problems of poor adaptability of manual plate cold forming machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific structure and working principle of the present invention will be further described below in conjunction with the accompanying drawings.

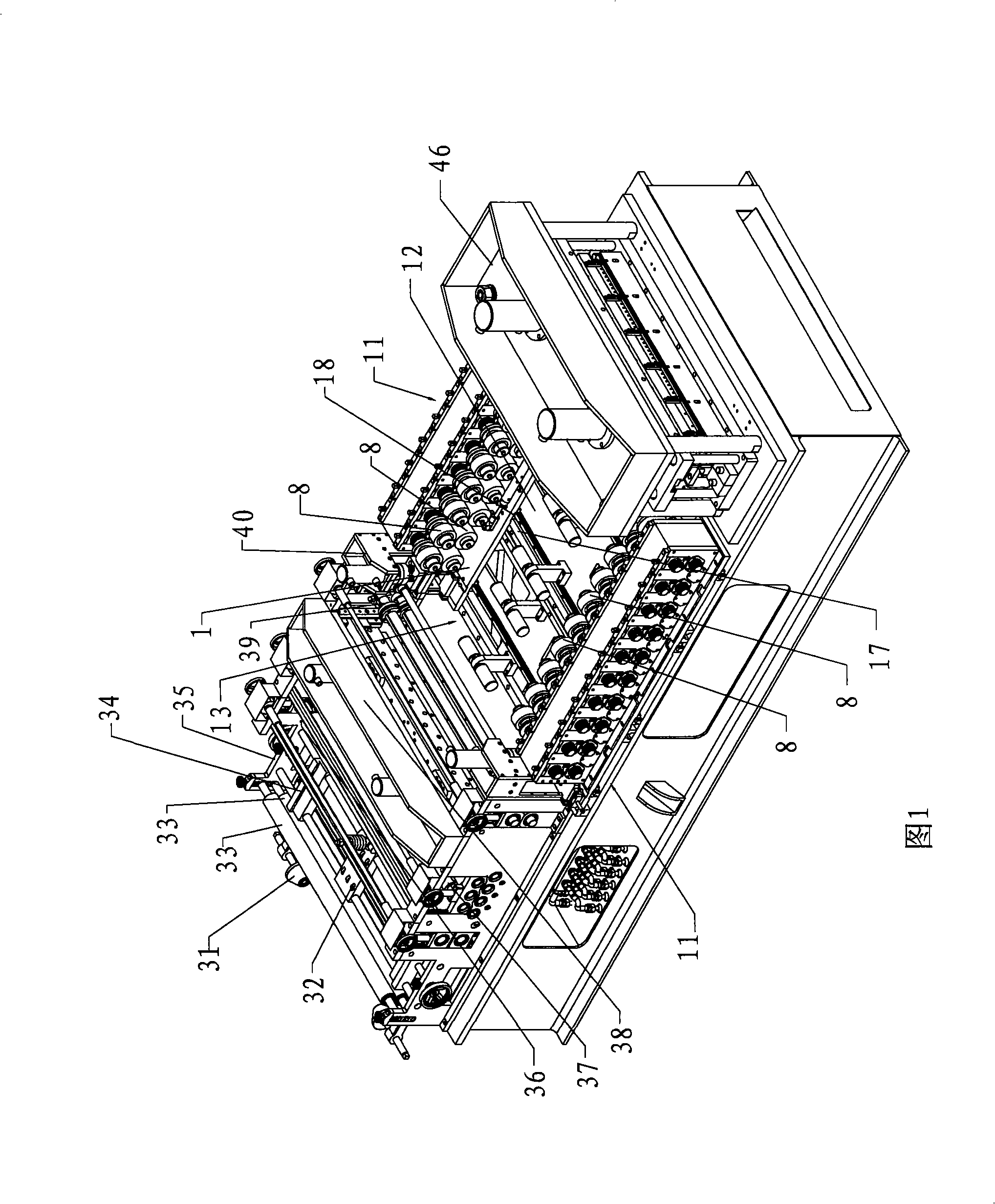

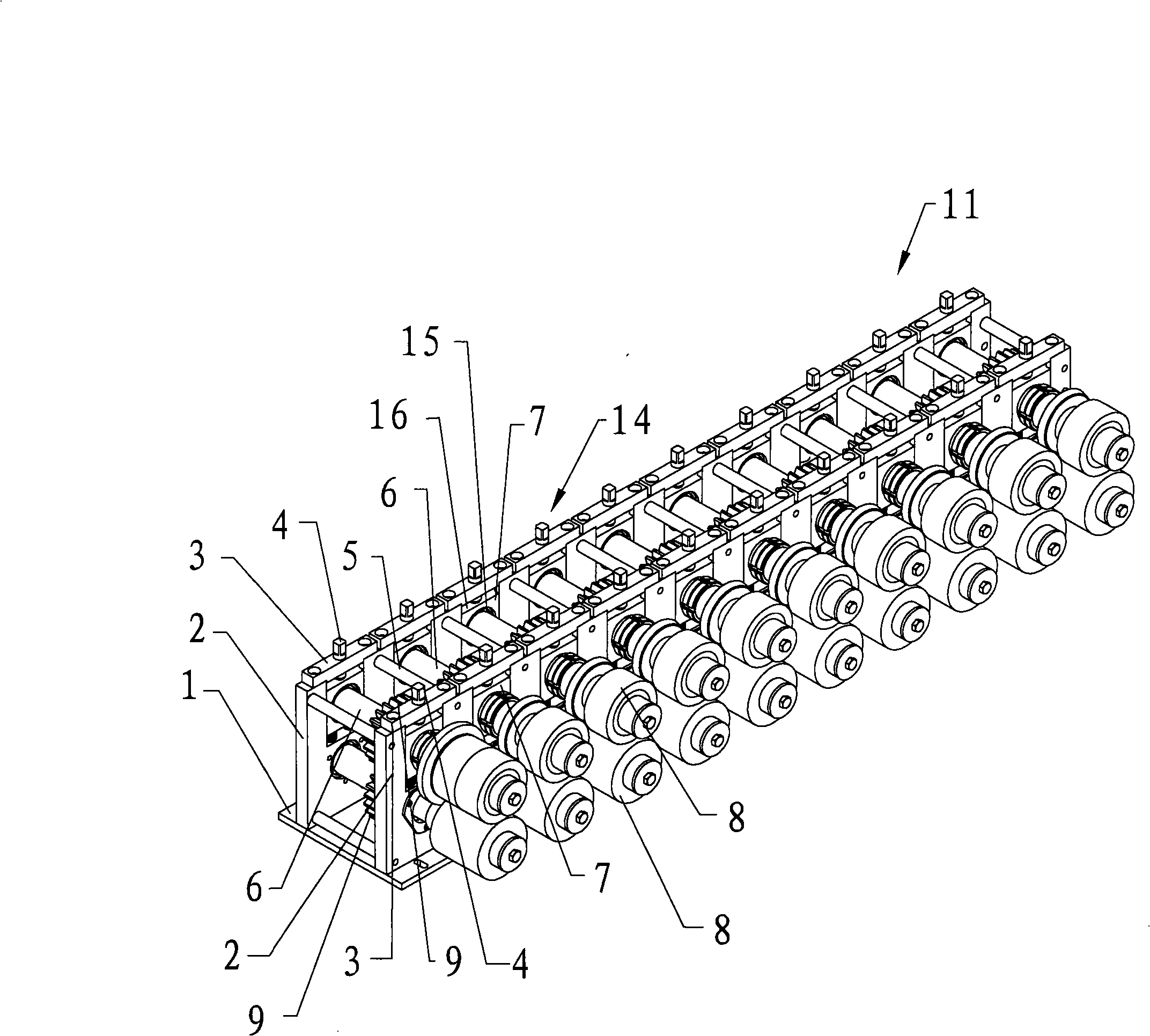

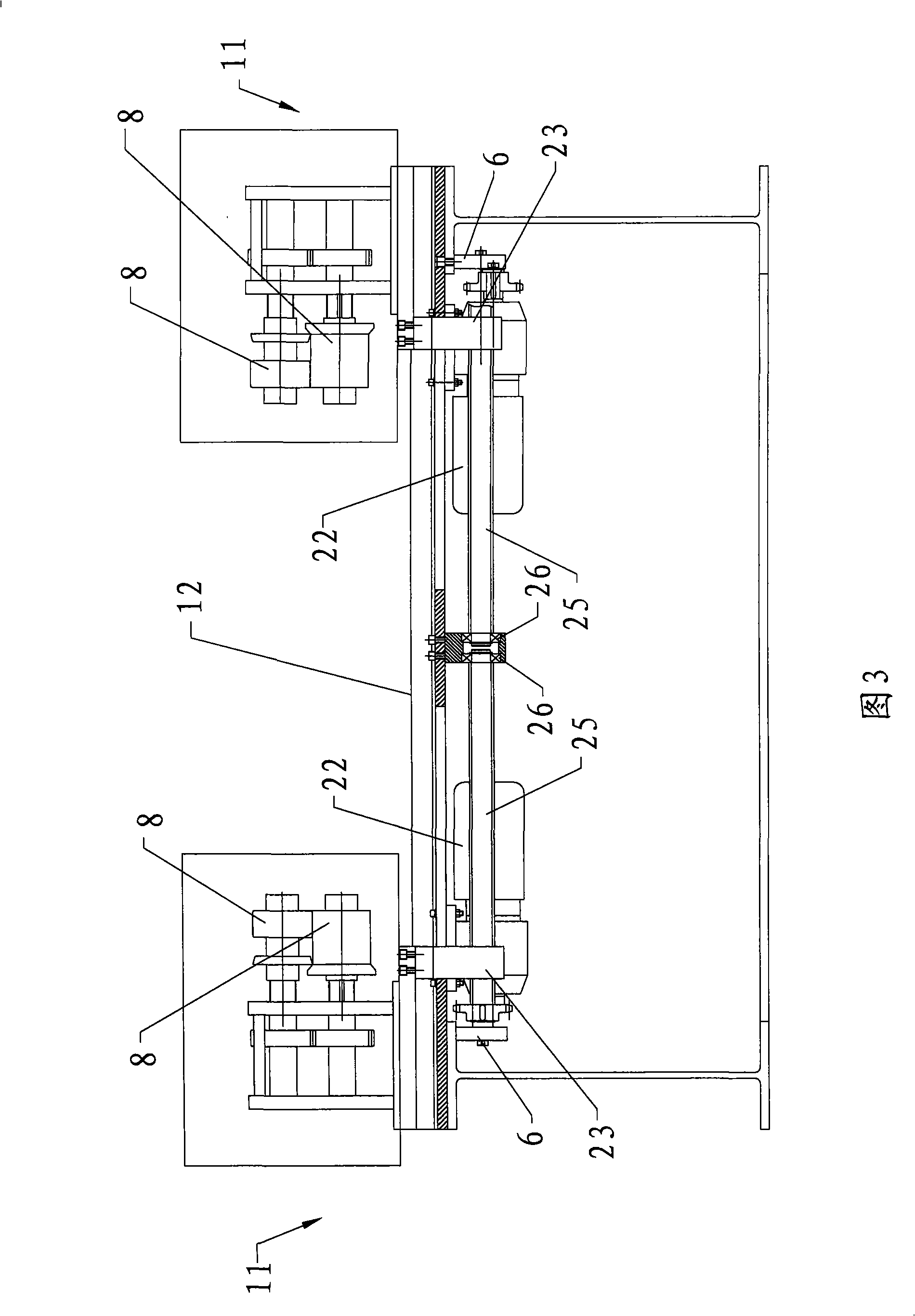

[0014] As shown in accompanying drawings 1-3, a kind of manual plate cold-bending forming machine comprises forming box body 11, and forming box body 11 is provided with the rolling wheel 8 that is used for extruding thin plate, and metal sheet is along the longitudinal direction of machine tool 12 automatic The feed material enters the forming structure after the flattening process and the shearing process, passes through the middle of the two rows of rolling wheels 8, and is extruded under the action of the rolling wheels 8. The main function of the forming box 11 is to transmit the power provided by the motor to the rolling wheel 8, and then realize the cold bending forming of the thin metal plate. The forming box 11 is detachably connected with the machine tool 12 of the cold roll forming machine. When the forming box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com