Gypsum board cutting control method and system with fixed length

A fixed-length cutting and control system technology, which is applied to the program control, electrical program control, and feedback control in the sequence/logic controller, can solve the problem that the cutting can only be controlled at about 2‰, and achieve The effect of improving shearing accuracy, system stability, and meeting process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

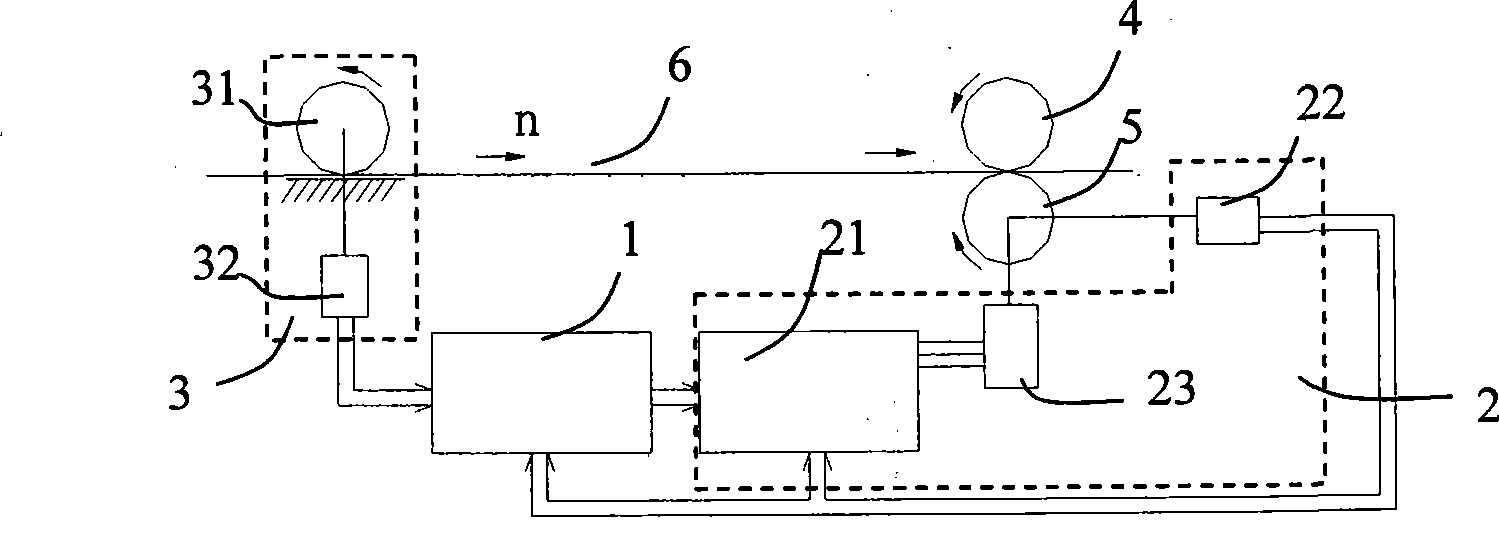

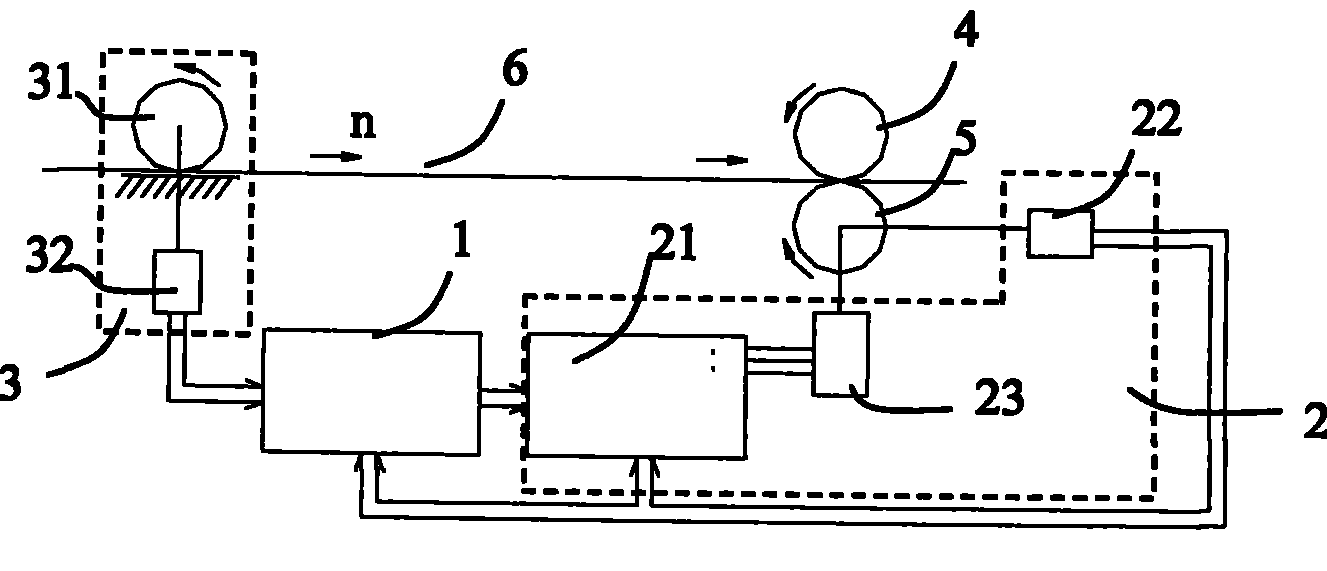

[0026] Such as figure 1 As shown, the present invention includes: a detection unit 3, a central processing unit 1 and a motor control unit 2, wherein,

[0027] The detection part 3 is used for online detection of the moving speed V of the gypsum board 6 l and length L;

[0028] The central processing unit 1 is used to process the data signal detected online by the detection unit 3, and output the control signal to the motor control unit 2;

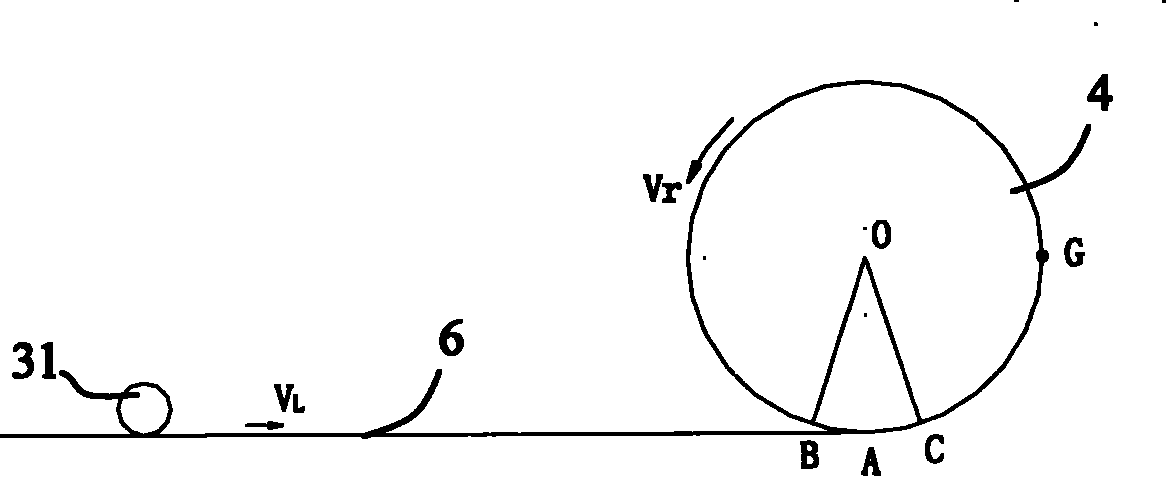

[0029] The motor control unit 2 is used to drive the knife rollers 4 and 5 to rotate in three speed zones: acceleration zone GB; synchronous zone BC; deceleration zone CG to rotate, such as figure 2 Shown, and make the speed of the knife edge of knife roller 4,5 meet in each district:

[0030] Acceleration zone GB: V r = V l · ( 1 ± ΔP N )

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com