Exterior-mounted star wheel motorized driving pulley

A technology of electric drum and star wheel, which is applied in hoisting device, transmission device, transportation and packaging, etc. It can solve the problems of wasting oil, short maintenance period, inconvenient maintenance, etc., and achieves wide range of speed ratio, reliable performance and convenient maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

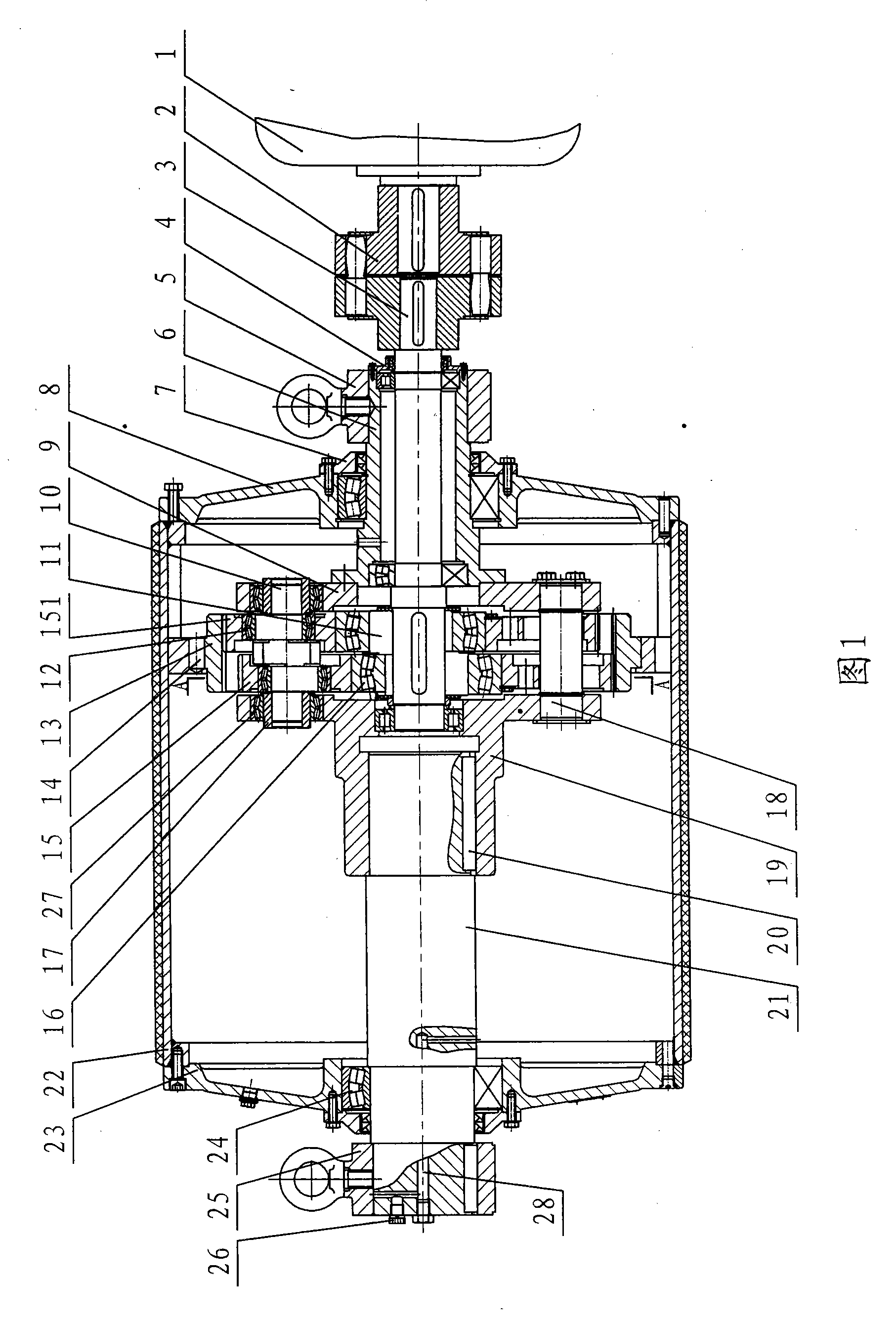

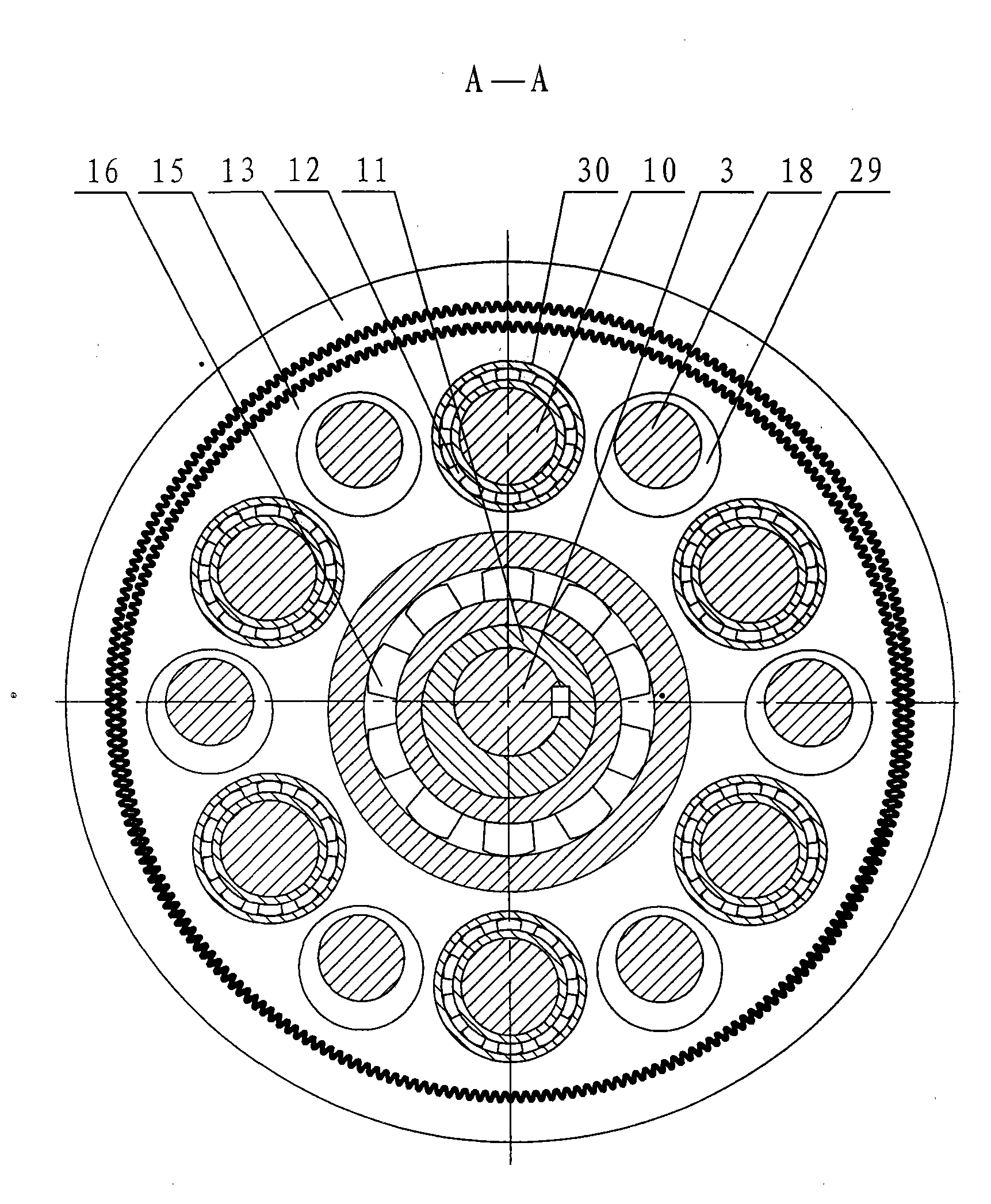

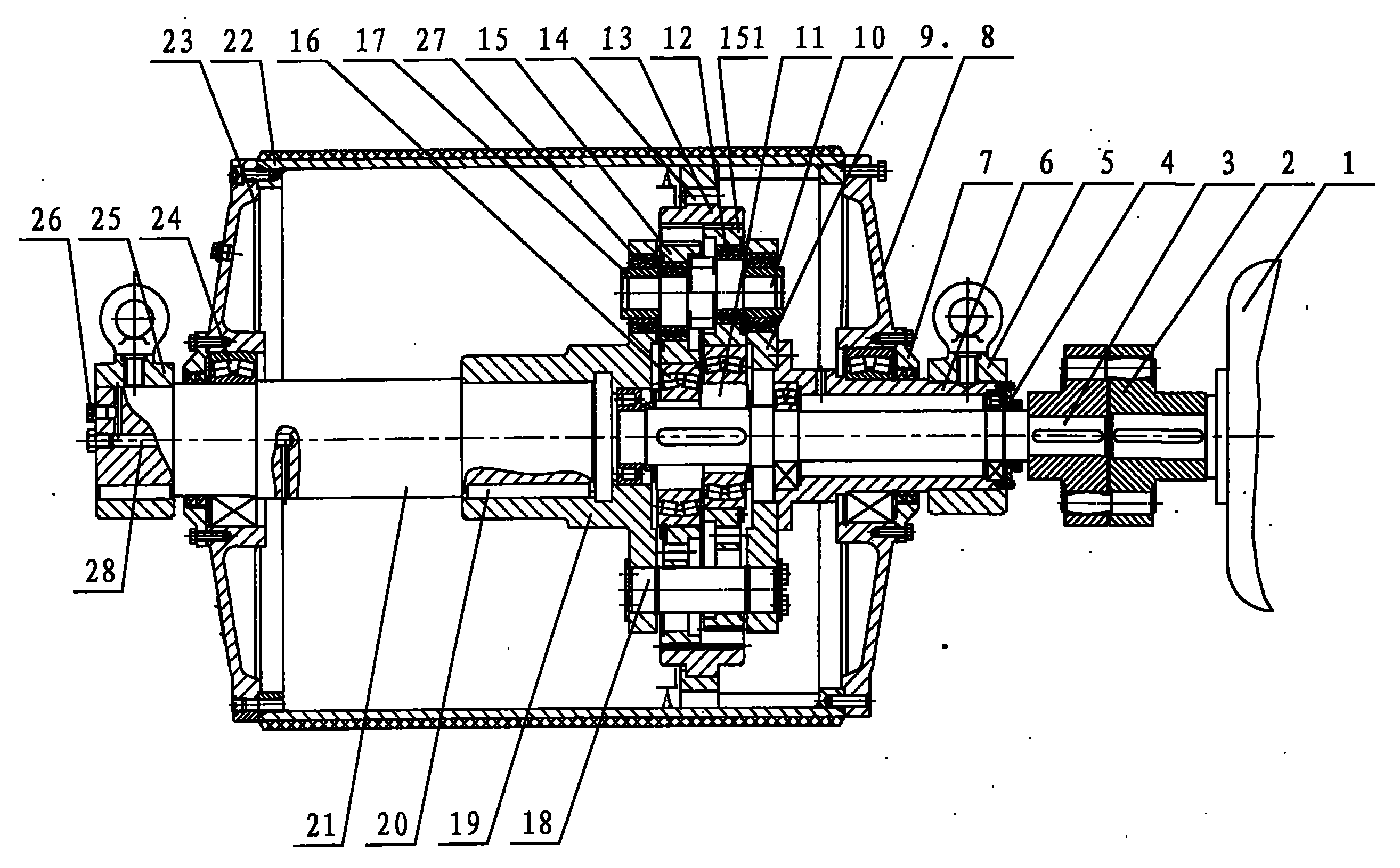

[0020] figure 1 , figure 2 An externally mounted star wheel electric drum shown in , the motor 1 is connected with the input shaft 3 through the coupling 2 (or hydraulic coupling), and the input shaft 3 is composed of the hollow shaft 6 and two short shafts in the hole of the left support plate 19. Cylindrical roller bearings and a spherical roller bearing support. The power is transmitted from the input shaft 3 to the eccentric sleeve 11 through the flat key. When the input shaft 3 rotates, the eccentric bearing 16 on the eccentric sleeve 11 pushes the two planetary brine wheels 15, 151 with identical technical parameters and 180° to each other to move. The rolling star wheel is composed of multiple eccentric star wheel shafts 10, bushes 17 installed at both ends and rolling bearings 27 on the bushings. The multiple eccentric star wheel shafts 10 respectively run through several eccentric star wheel shafts evenly distributed at concentric intervals on the planetary gear. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com