Drive pulley used on large-scale building mechanical equipment

A technology for construction machinery and transmission belts, applied in mechanical equipment, belts/chains/gears, components with teeth, etc., to achieve smooth transmission, obvious energy-saving effect, and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

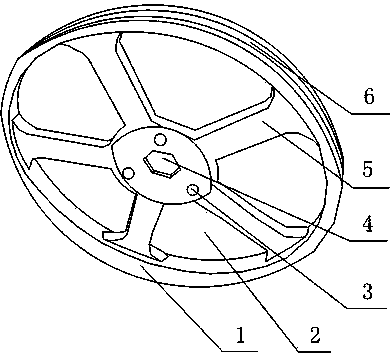

[0015] Such as figure 1 As shown, the transmission pulley used on large-scale construction machinery equipment includes a pulley body 1 , and several grooves 6 are arranged on the circumferential surface of the pulley body 1 . Groove 6 is for placing belt.

[0016] The center of the pulley body 1 is provided with a through hole 4 .

[0017] The shape of the through hole 4 is rhombus. By setting the through hole 4 as a rhombic hole, the connection between the pulley body 1 and the power element is more stable during the rotation process, and no slippage will occur.

[0018] The pulley body 1 is provided with several threaded through holes 3 .

[0019] The number of the threaded through holes 3 is three, and they are evenly distributed around the through holes 4 . The fixing degree between the pulley body 1 and other components is increased through the threaded through hole 3 .

[0020] Several cavities 2 are provided on the pulley body 1 , and the cavities 2 have the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com