Desalination plant using residual heat of thermal superconductivity of heat pipe and engine high-temperature exhaust air

An engine and thermal superconducting technology, applied in seawater treatment, heating water/sewage treatment, general water supply saving, etc., can solve the problems of easy scaling and high energy consumption, and achieve the effect of lower cost and lower resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

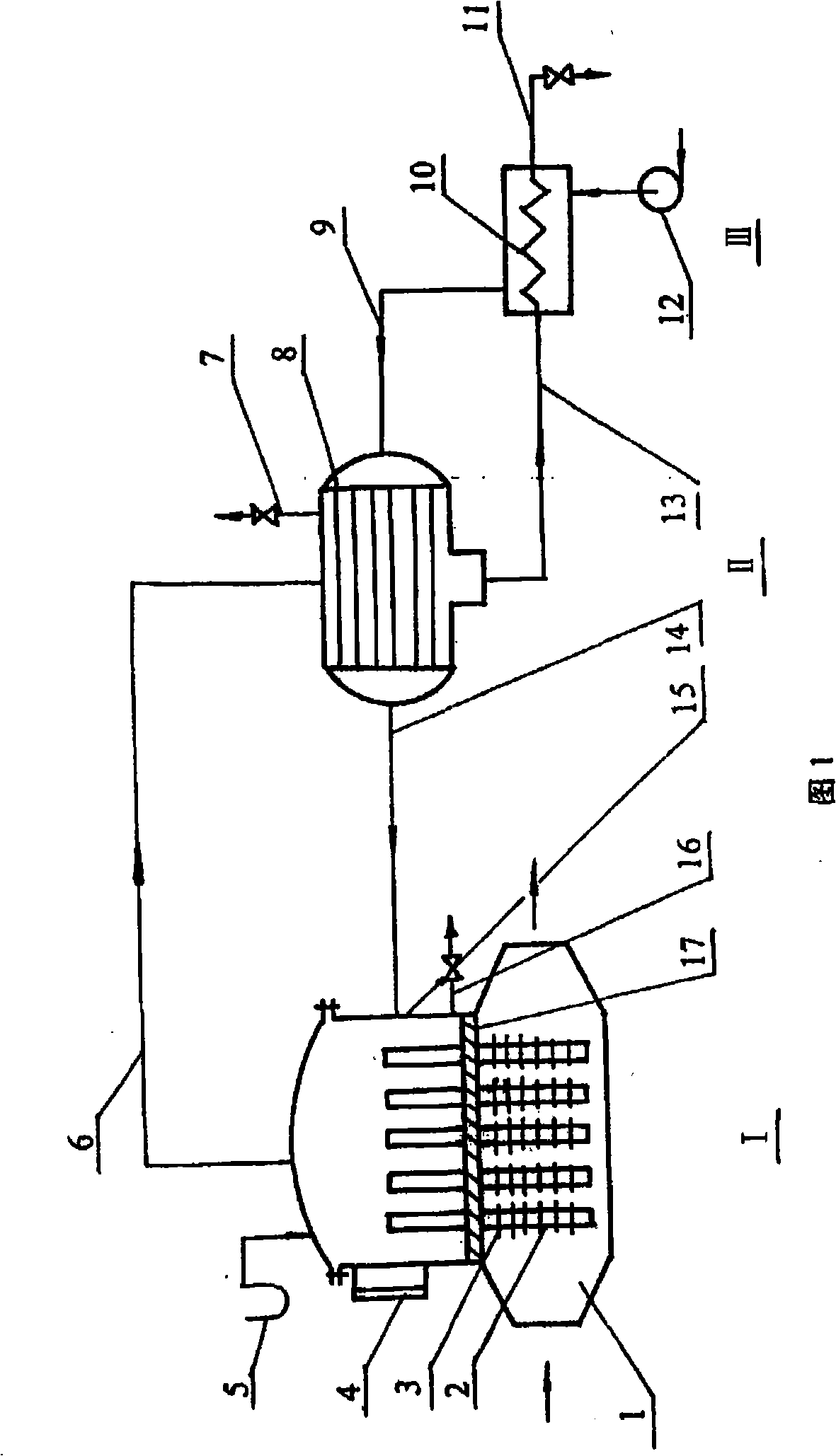

[0007] Embodiment: A waste heat seawater desalination device adopting heat pipe thermal superconductivity and engine high-temperature exhaust. The water pump 12 passes the seawater through the coil 10 of the preheater, and the heat exchange tube 8 of the steam condenser 11 enters the heat pipe evaporator , the heat pipe evaporator is installed on the exhaust pipe of the engine. After the high-temperature exhaust of the engine passes through the channel 1 arranged with heat pipes, the heat of the flue gas is quickly transferred to the seawater on the upper part of the evaporator inner partition 17 by the heat pipe 2. The temperature of the seawater rises rapidly, and a large amount of water vapor is generated, which enters the heat exchange tube 8 of the steam condenser 11 through the steam conduit 6, and is cooled by the seawater in the tube to become distilled water, and the distilled water enters the coil 10 of the preheater through the conduit 13 Inside, it is cooled by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com