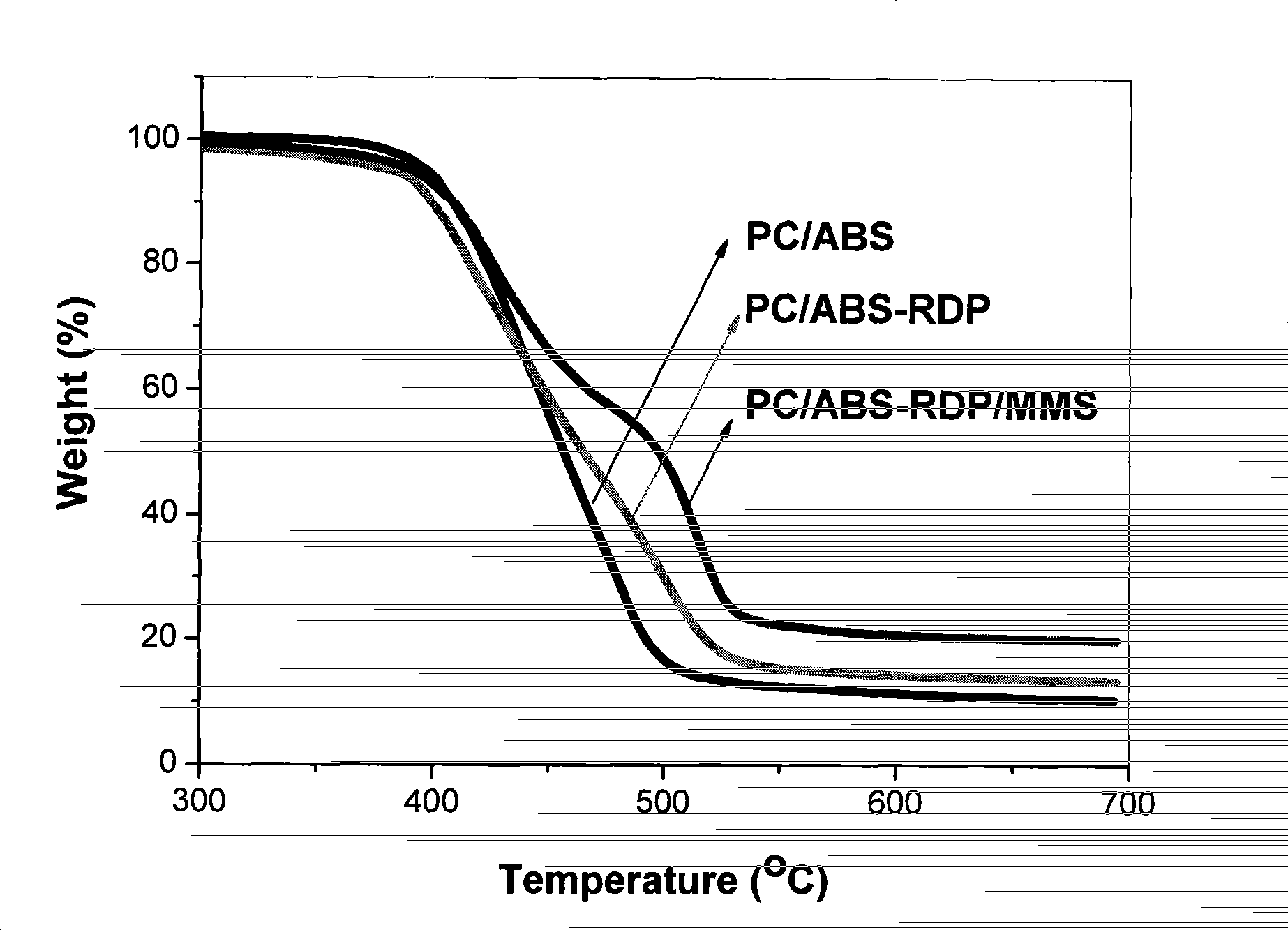

Organic-inorganic composite flame retardants with mesoporous molecular sieve and method for preparing same

A mesoporous molecular sieve and inorganic composite technology, applied in the field of polymers, to achieve the effects of improved thermal stability, huge specific surface area, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

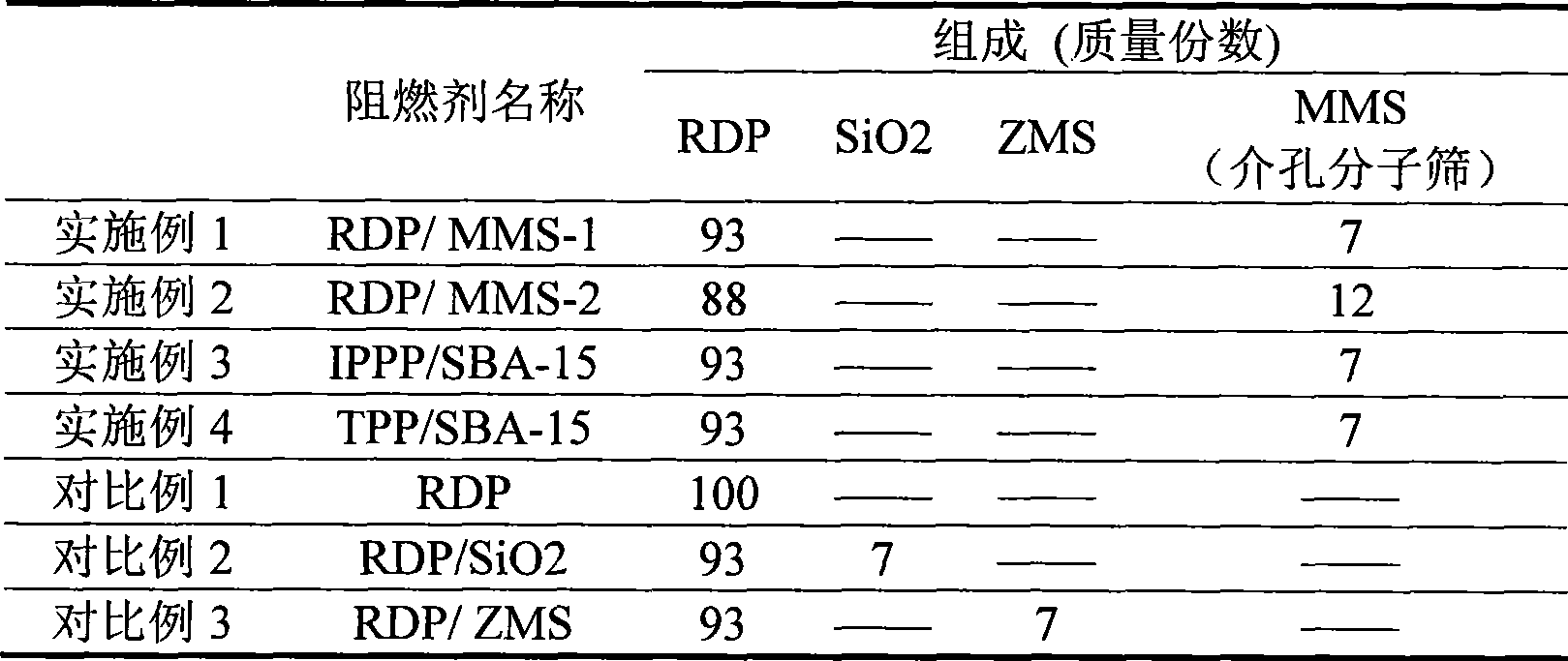

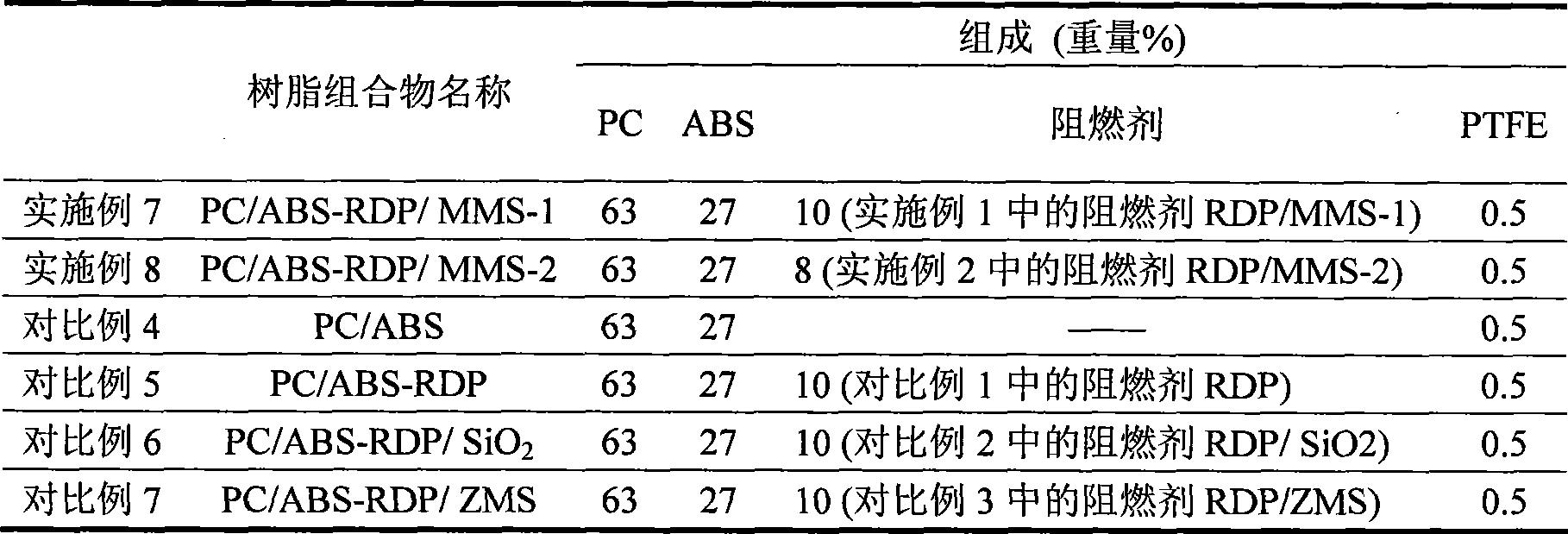

Embodiment 1

[0067] Drying of mesoporous molecular sieves: Dry 21g of MCM-41 mesoporous molecular sieves at 250°C for 2 hours under a vacuum condition with a pressure less than 0.1MPa to remove moisture and small air molecules in the pores of the molecular sieves;

[0068] Flame retardant pretreatment: Thin the viscosity of 279g liquid RDP flame retardant at 100°C to obtain a flame retardant liquid with better fluidity;

[0069] Immersion of mesoporous molecular sieve powder and flame retardant: In vacuum conditions with a pressure less than 0.1MPa, introduce the pretreated RDP flame retardant liquid into the dried MCM-41 mesoporous molecular sieve, so that the flame retardant liquid and the medium Porous molecular sieves are fully soaked, soaked at 100°C for 3 hours, and at room temperature for 20 hours;

[0070] Post-treatment of the flame retardant: the obtained flame retardant vacuum-soaked mesoporous molecular sieve system was ultrasonically oscillated at a frequency of 59kHz for 1h, ...

Embodiment 2

[0072] Drying of mesoporous molecular sieves: Dry 36g of MCM-41 mesoporous molecular sieves at 250°C for 2 hours under vacuum conditions with a pressure less than 0.1MPa to remove moisture and small air molecules in the pores of the molecular sieves;

[0073] Flame retardant pretreatment: Thin the viscosity of 264g liquid RDP flame retardant at 100°C to obtain a flame retardant liquid with better fluidity;

[0074] Immersion of mesoporous molecular sieve powder and flame retardant: In vacuum conditions with a pressure less than 0.1MPa, introduce the pretreated RDP flame retardant liquid into the dried MCM-41 mesoporous molecular sieve, so that the flame retardant liquid and the medium Porous molecular sieves are fully soaked, soaked at 100°C for 3 hours, and at room temperature for 20 hours;

[0075]Post-treatment of the flame retardant: the obtained flame retardant vacuum-soaked mesoporous molecular sieve system was ultrasonically oscillated at a frequency of 59kHz for 1h, an...

Embodiment 3

[0077] Drying of mesoporous molecular sieves: Dry 21g of SBA-15 mesoporous molecular sieves at 220°C for 5 hours under vacuum conditions with a pressure less than 0.1MPa to remove moisture and small air molecules in the pores of the molecular sieves;

[0078] Flame retardant pretreatment: Thin the viscosity of 279g of liquid IPPP flame retardant at 100°C to obtain a flame retardant liquid with better fluidity;

[0079] Immersion of mesoporous molecular sieve powder and flame retardant: In vacuum conditions with a pressure less than 0.1MPa, introduce the pretreated IPPP flame retardant liquid into the dried SBA-15 mesoporous molecular sieve, so that the flame retardant liquid and the medium Porous molecular sieves are fully soaked, soaked at 90°C for 2 hours, and at room temperature for 25 hours;

[0080] Post-treatment of the flame retardant: the obtained flame retardant vacuum-soaked mesoporous molecular sieve system was oscillated with ultrasonic waves at a frequency of 100k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com