Activation method for quickly generating phosphatic rock on titanium coating surface

An activation method, titanium coating technology, applied in coating, medical science, prosthesis, etc., can solve problems such as gaps, and achieve the effect of excellent biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The substantive characteristics and remarkable effects of the present invention are further illustrated below through the introduction of the embodiments. But in no way limit the invention.

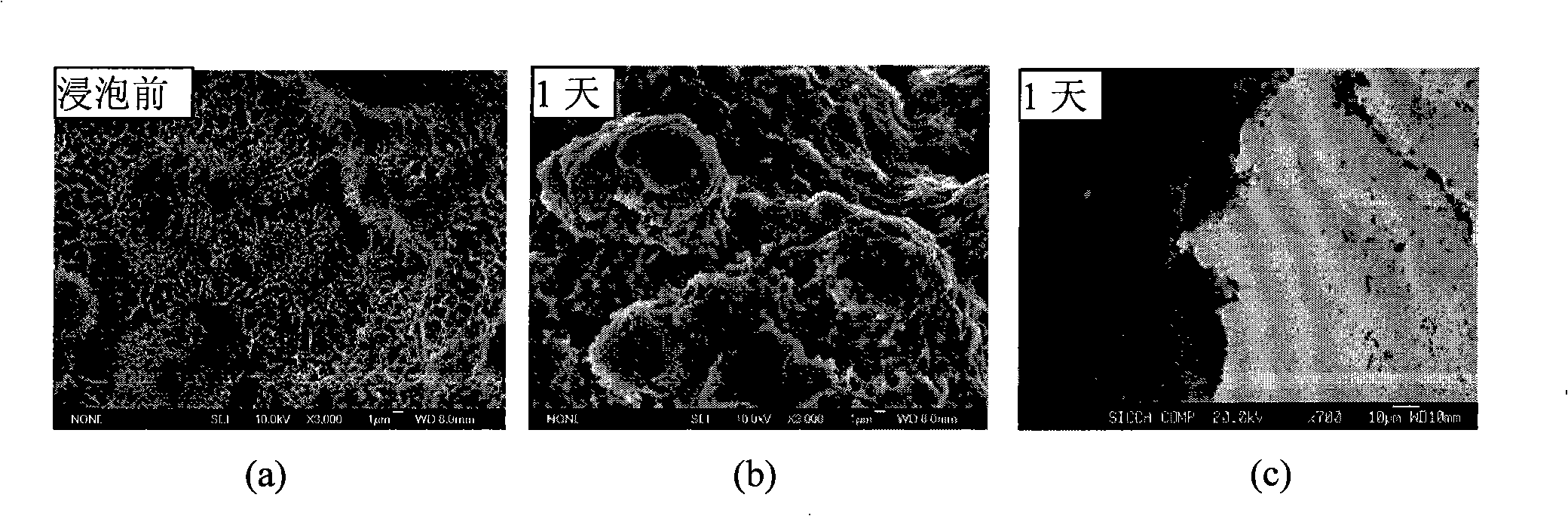

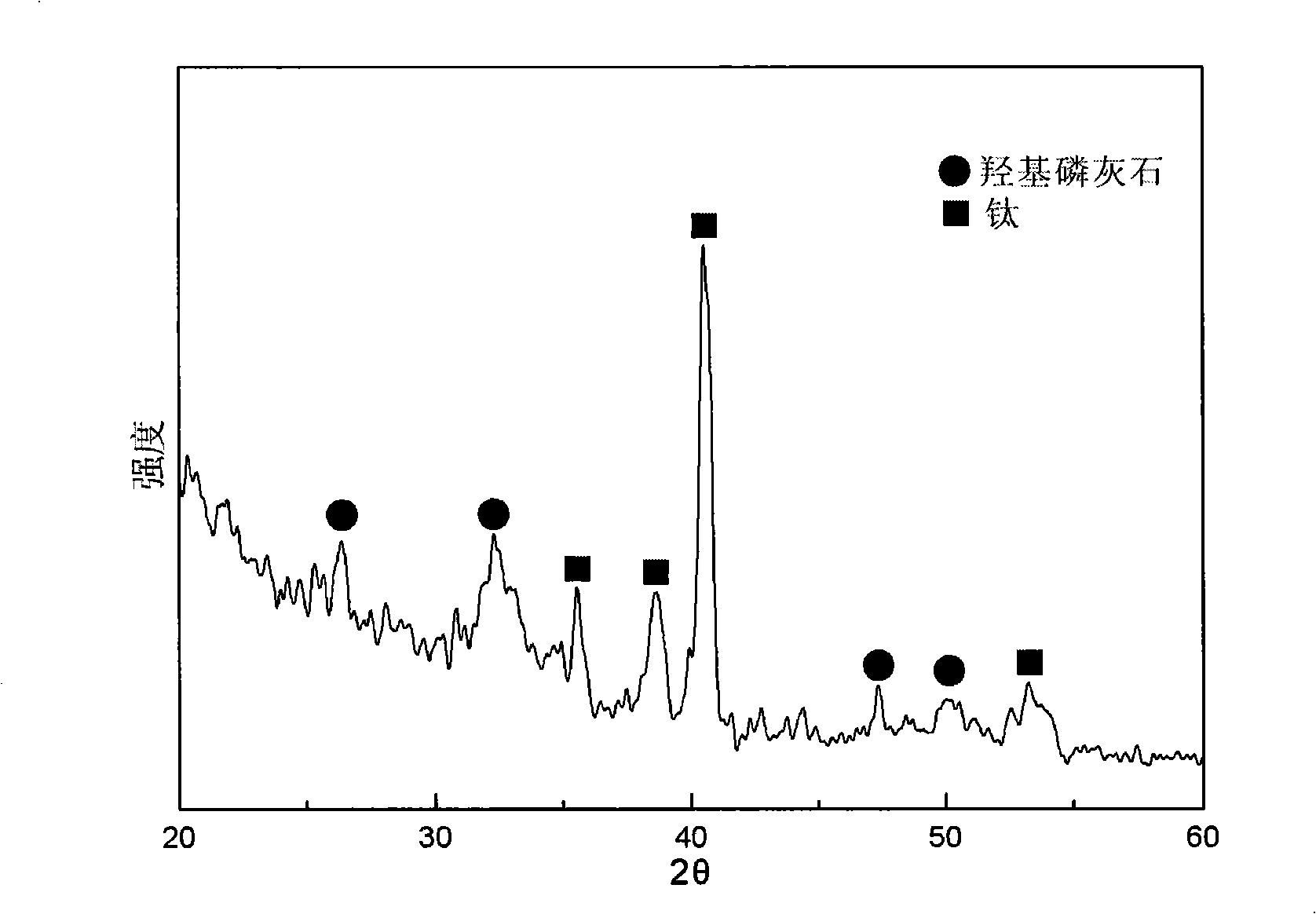

[0013] The titanium coating was prepared by vacuum plasma spraying technology. The prepared titanium coating was immersed in 5M NaOH solution and kept at 60°C for 24 hours. After taking it out, it was ultrasonically cleaned with deionized water for 3 times, each time for 5 minutes, and then immersed in deionized water. , kept at 40°C for 48h, then dried at 40°C for 24h, and the dried sample was heat-treated at 600°C for 1h. The heat-treated samples were immersed in a supersaturated calcium phosphate solution, kept at 25°C for 48 hours, and taken out to dry naturally. The preparation method of supersaturated calcium phosphate solution is as follows: Weigh 8.300g NaCl, 0.4162g CaCl 2 , 0.3423g K 2 HPO 4 ·3H 2 O was put into 1000ml deionized water, and the pH value of the solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap