Bottle burying machine

A bottle unscrambler and bottle feeding technology, which is applied in the field of bottle unscramblers for conveying old beer bottles, can solve the problems of high labor intensity, low production efficiency, and large manpower consumption, and achieve the effect of reducing production costs and improving the competitiveness of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

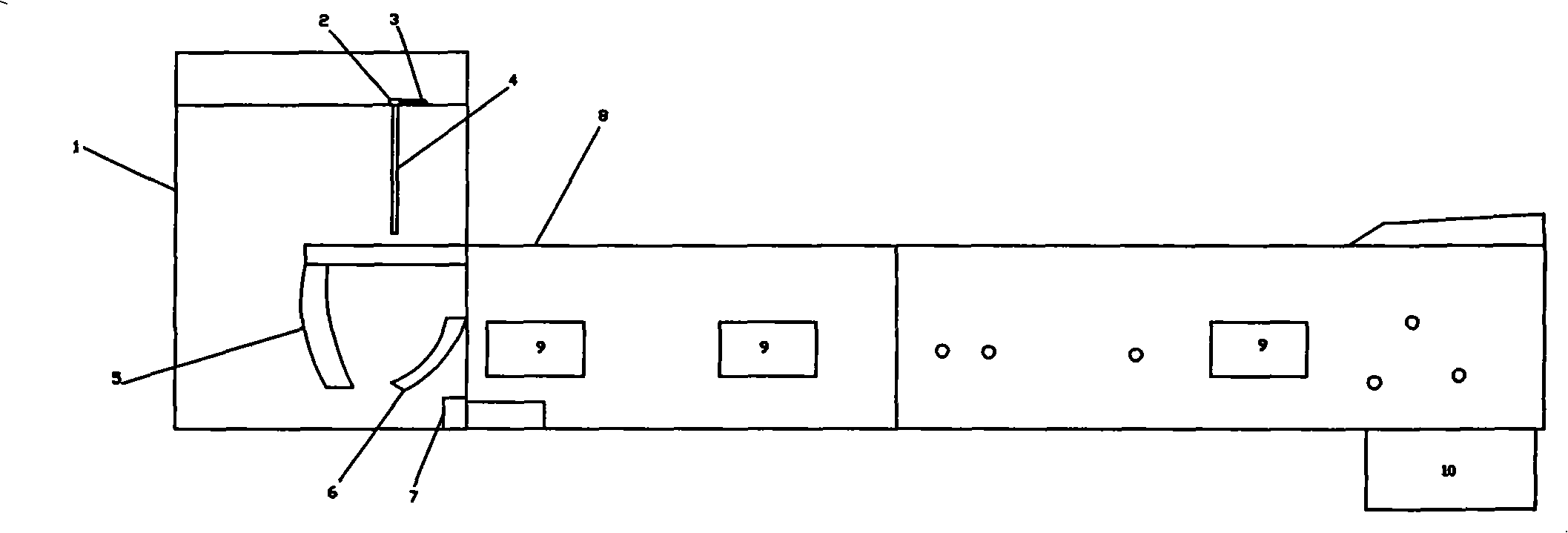

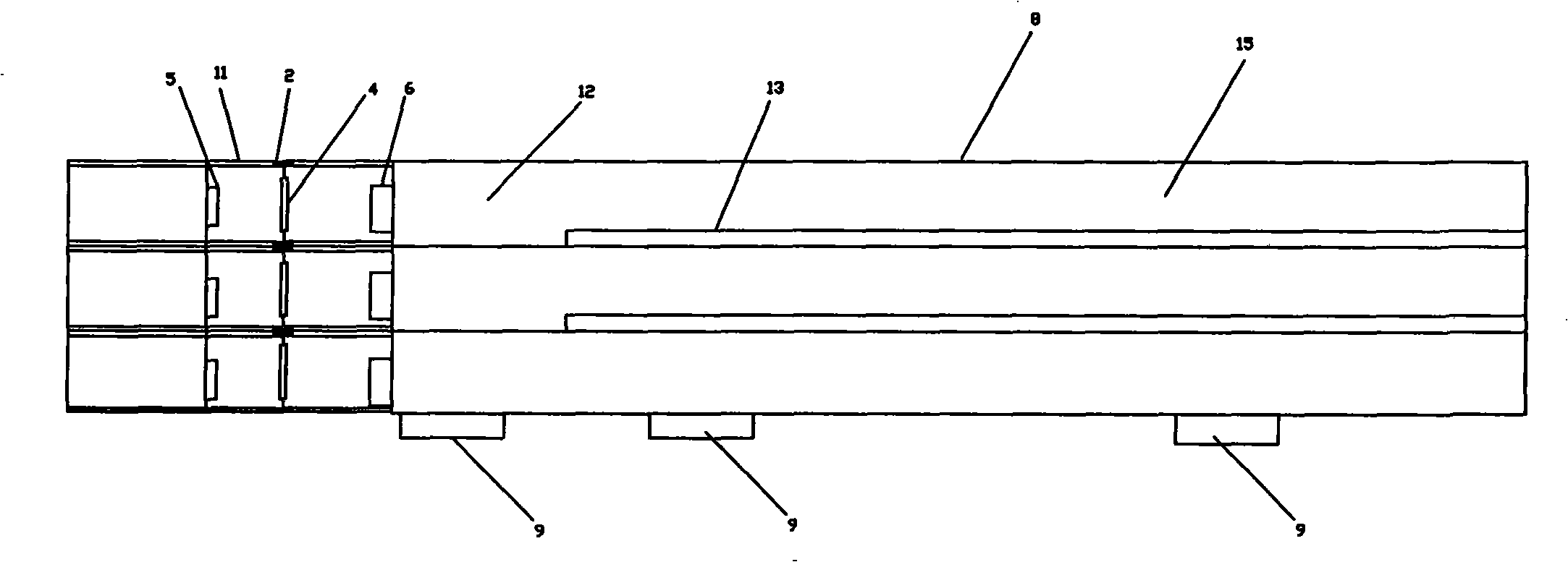

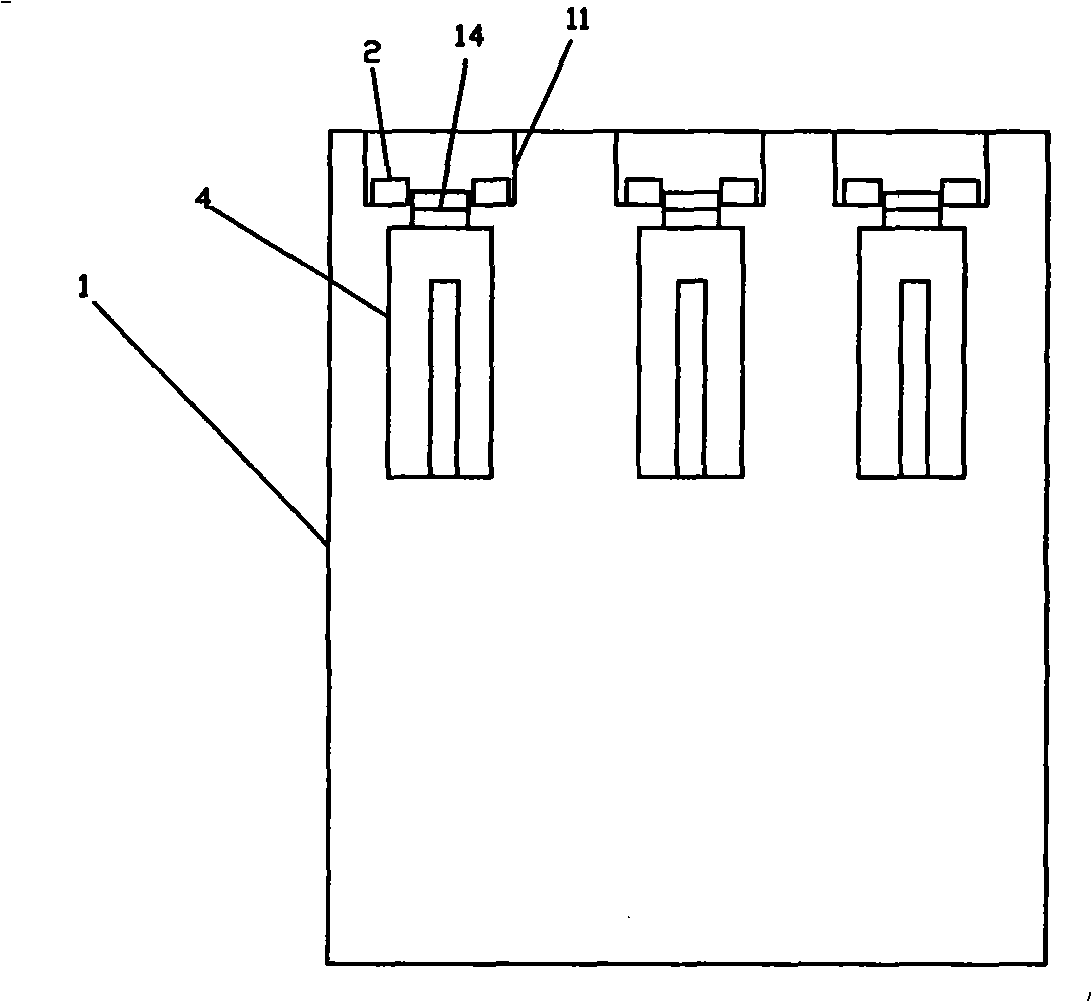

[0024] figure 1 , figure 2 , image 3 Among them, the bottle unscrambler includes a bottle feeding device, the lower part of the device is connected with the power unit, and the device is also connected with the speed regulating device; the running end of the bottle feeding device is connected with the bottle dropper, and the bottle dropper is connected with the bottle pushing device.

[0025] The bottle feeding device is a box body 8, three conveying troughs 12 are arranged at the bottom of the box body 8, and a conveying crawler 15 is arranged in each conveying trough 12, and the conveying crawler 15 is connected with a speed regulating device, and the speed regulating device is a speed regulating machine 9 . Both sides of the delivery tank 12 are provided with bottle position adjustment devices. The bottle position adjustment device is a pair of adjustment grooves 13, and the adjustment grooves 13 are installed on both sides of the delivery groove 12. Each adjustment gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com